High-sound pressure microphone-oriented amplitude- and frequency-adjustable calibrator with traceability

A microphone and calibrator technology, applied in the measurement of ultrasonic/sonic/infrasonic waves, instruments, measuring devices, etc., can solve the problems of single frequency, high sound pressure standard microphones that cannot be traced, and achieve the effect of fast and convenient installation and solving traceability problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

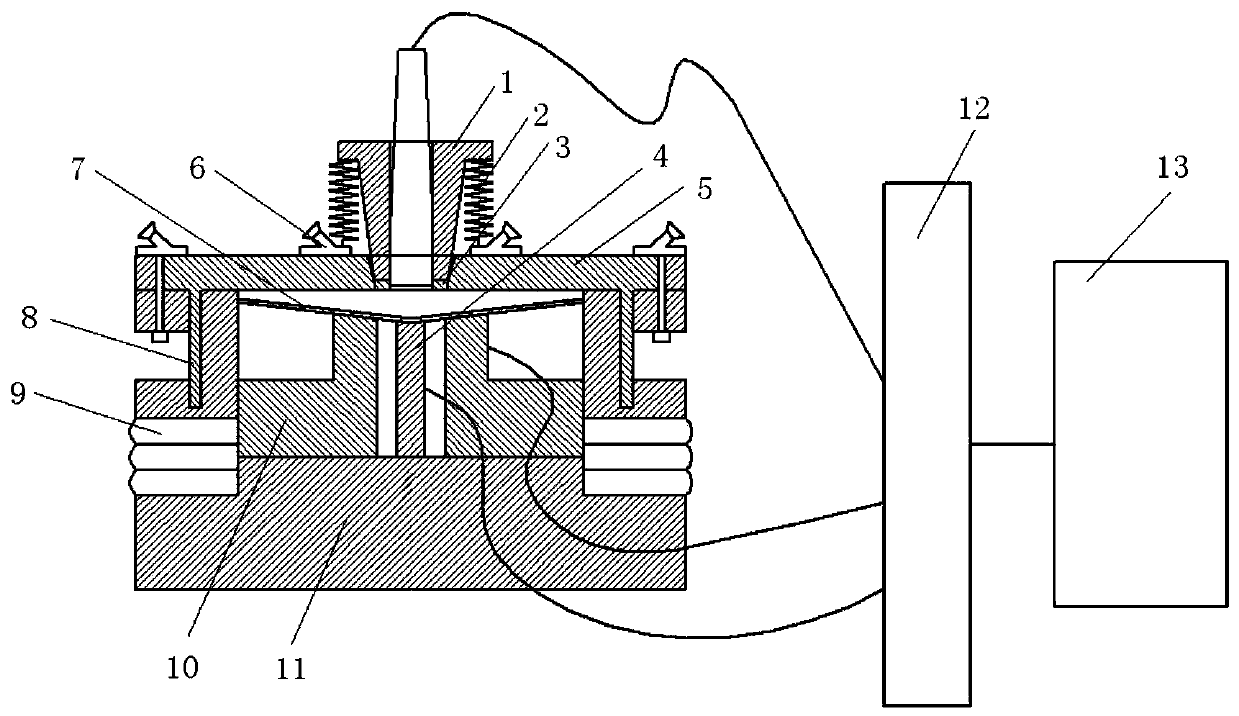

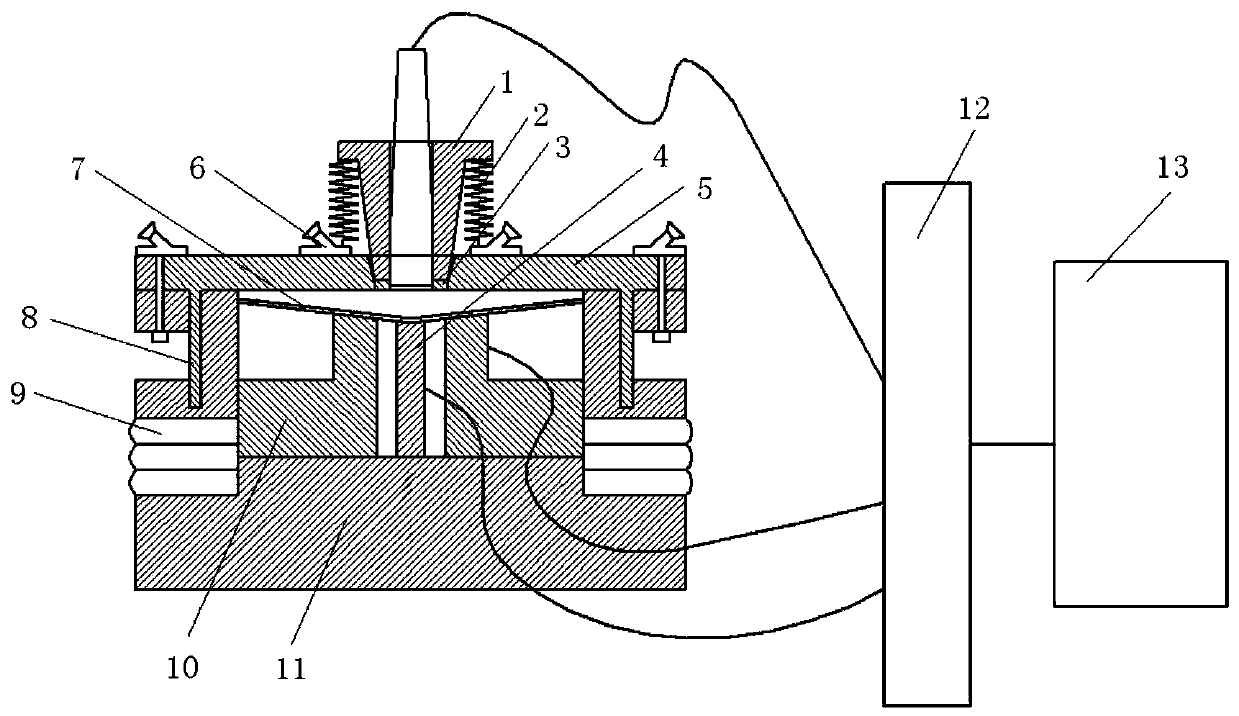

[0041] Such as figure 1 As shown, this embodiment discloses a traceable high sound pressure microphone calibrator with adjustable amplitude and frequency, and the calibration object is any high sound pressure microphone. This embodiment includes a microphone installation structure, a microphone pretension structure, a high sound pressure absolute method closed-loop real-time feedback measurement and control system 12 and a diaphragm 7 system for generating high sound pressure. The diaphragm 7 system for generating high sound pressure includes a replaceable coupling cavity 5 , a diaphragm 7 , and a driver 10 .

[0042] The gland 1 is used to compress the calibrated high sound pressure microphone 4 to tightly couple with the coupling cavity 5;

[0043] The pre-tightening spring 2 is used to adjust the pre-tightening force of the gland 1 to ensure that there will be no sound leakage;

[0044] The trapezoidal rubber ring 3 is used to realize air sealing and compression of the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com