Fabrication method of terahertz metal-coated hollow rectangular waveguide combination

A technology of metal plating and rectangular waveguide, which is applied to waveguides, waveguide devices, circuits, etc., can solve the problems of gold plating layer and cast copper layer damage, difficult removal of dissolved products, deformation, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the content of the present invention easier to understand, the present invention will be further explained in detail below based on a manufacturing verification example of a "concave" cavity combined with the accompanying drawings.

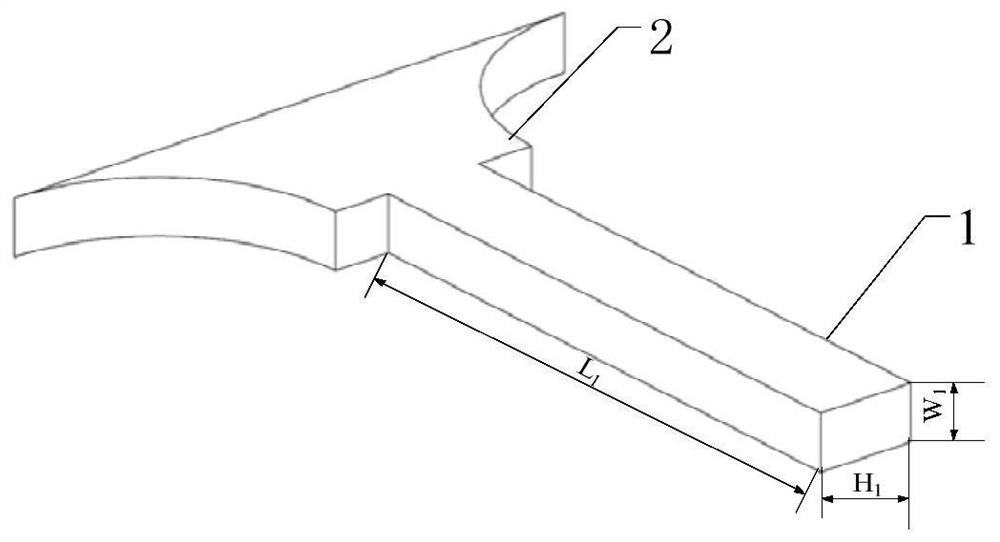

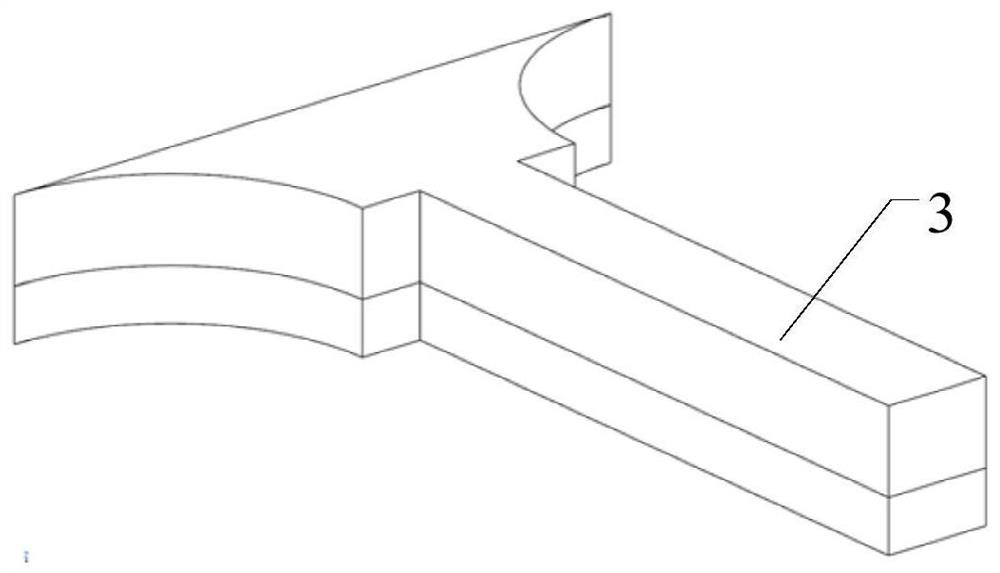

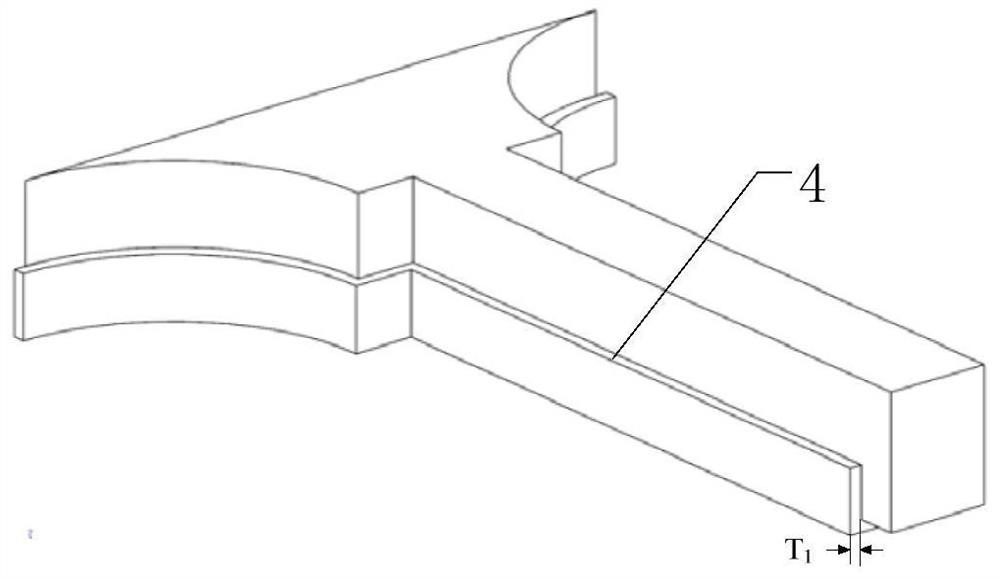

[0047] Figure 1-1 to Figure 1-8 The "concave" cavity fabrication process is illustrated. like Picture 1-1 , Figure 1-2 As shown, after the fine electrolytic wire cutting of the first rectangular sacrificial mandrel is completed, since the width of the rectangular sacrificial mandrel is greater than its height, generally one surface is selected in the width direction and insulated with insulating glue. like Figure 1-3 , Figure 1-4 As shown, the three non-insulated surfaces of the rectangular sacrificial mandrel after one-sided insulation are electroplated with gold layer and electroformed copper layer in sequence. like Figure 1-5 , Figure 1-6 As shown in Fig. 1, the insulating glue is removed and the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com