A tissue engineering scaffold suitable for the construction of human organs and its preparation method

A technology for tissue engineering scaffolds and organs, applied in prosthetics, medical science, etc., can solve the problems of material pore size, poor smoothness, poor biological and histocompatibility, and mismatched cell growth conditions, and achieve superior application value , Uniform pore size and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

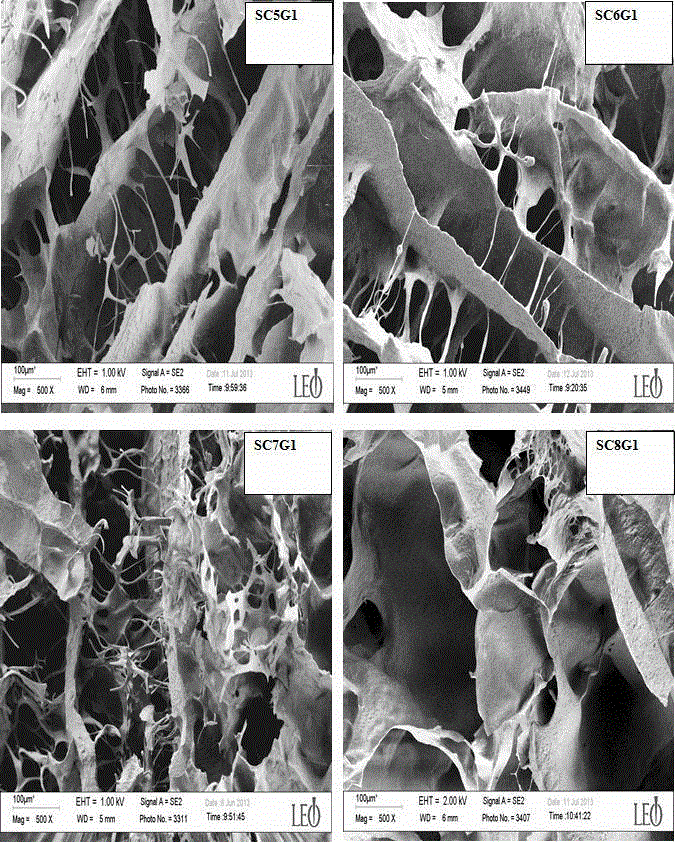

Embodiment 1

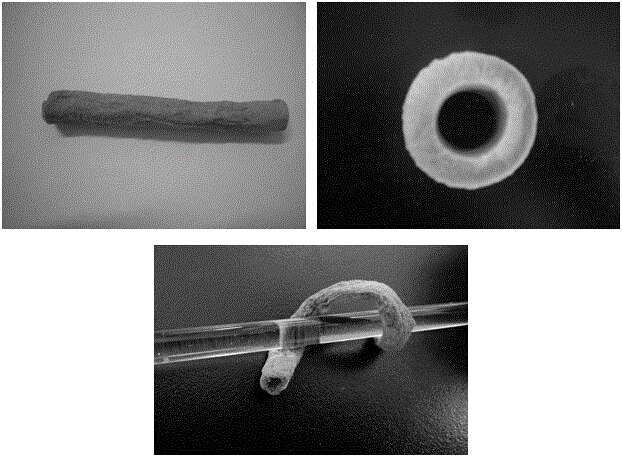

[0037] A preparation method for a tissue engineering scaffold suitable for human organ construction, specifically comprising the following steps:

[0038] (1) Dissolve sericin powder in deionized water to prepare a sericin solution with a concentration of 5.0% (W / V);

[0039] Chitosan is dissolved in the dilute hydrochloric acid solution that concentration is 0.1mol / L, is made into the chitosan solution that concentration is 2% (W / V);

[0040] Dissolve sodium glycerophosphate in deionized water to prepare a sodium glycerophosphate solution with a concentration of 50% (W / V);

[0041] (2) Below 20°C, weigh 0.68ml of the sericin solution obtained in step (1) and 5ml of the chitosan solution, stir and mix evenly, then add 1ml of the sodium glycerophosphate solution obtained in step (1) dropwise, and stir 30min;

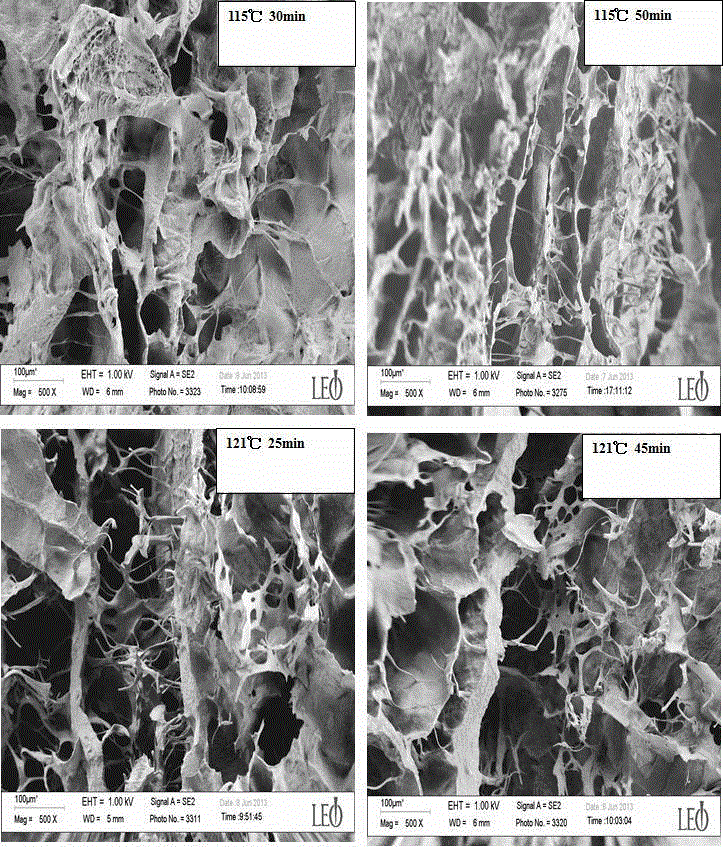

[0042] Put the mixed solution into the mold, control the temperature of the mold at 37°C, and make the mixed solution gel into shape; then place the molded material at -2...

Embodiment 2

[0044] A preparation method for a tissue engineering scaffold suitable for human organ construction, specifically comprising the following steps:

[0045] (1) Dissolve sericin powder in deionized water to prepare a sericin solution with a concentration of 5.0% (W / V);

[0046] Chitosan is dissolved in the dilute hydrochloric acid solution that concentration is 0.1mol / L, is made into the chitosan solution that concentration is 2% (W / V);

[0047] Dissolve sodium glycerophosphate in deionized water to prepare a sodium glycerophosphate solution with a concentration of 50% (W / V);

[0048] (2) Below 20°C, weigh 0.68ml of the sericin solution obtained in step (1) and 6ml of the chitosan solution, stir and mix evenly, then add 1ml of the sodium glycerophosphate solution obtained in step (1) dropwise, and stir 30min;

[0049] Put the mixed solution into the mold, control the temperature of the mold at 37°C, and make the mixed solution gel into shape; then place the molded material at ...

Embodiment 3

[0051] A preparation method for a tissue engineering scaffold suitable for human organ construction, specifically comprising the following steps:

[0052] (1) Dissolve sericin powder in deionized water to prepare a sericin solution with a concentration of 5.0% (W / V);

[0053] Chitosan is dissolved in the dilute hydrochloric acid solution that concentration is 0.1mol / L, is made into the chitosan solution that concentration is 2% (W / V);

[0054] Dissolve sodium glycerophosphate in deionized water to prepare a sodium glycerophosphate solution with a concentration of 50% (W / V);

[0055] (2) Below 20°C, weigh 0.68ml of the sericin solution obtained in step (1) and 7ml of the chitosan solution, stir and mix evenly, then add 1ml of the sodium glycerophosphate solution obtained in step (1) dropwise, and stir 30min;

[0056] Put the mixed solution into the mold, control the temperature of the mold at 37°C, and gel the mixed solution into shape; then place the molded material at -20°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com