Eccentric block provided with movable counterweight block, vibrator and vibration screen

A technology of counterweight and eccentric block, which is used in filter screens, chemical instruments and methods, solid separation, etc., can solve the problems of high strength requirements of suspension columns, high cost of vibration-absorbing chassis, and rotation and wear of suspension columns. Compact, resonance amplitude reduction, stiffness and small compression effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

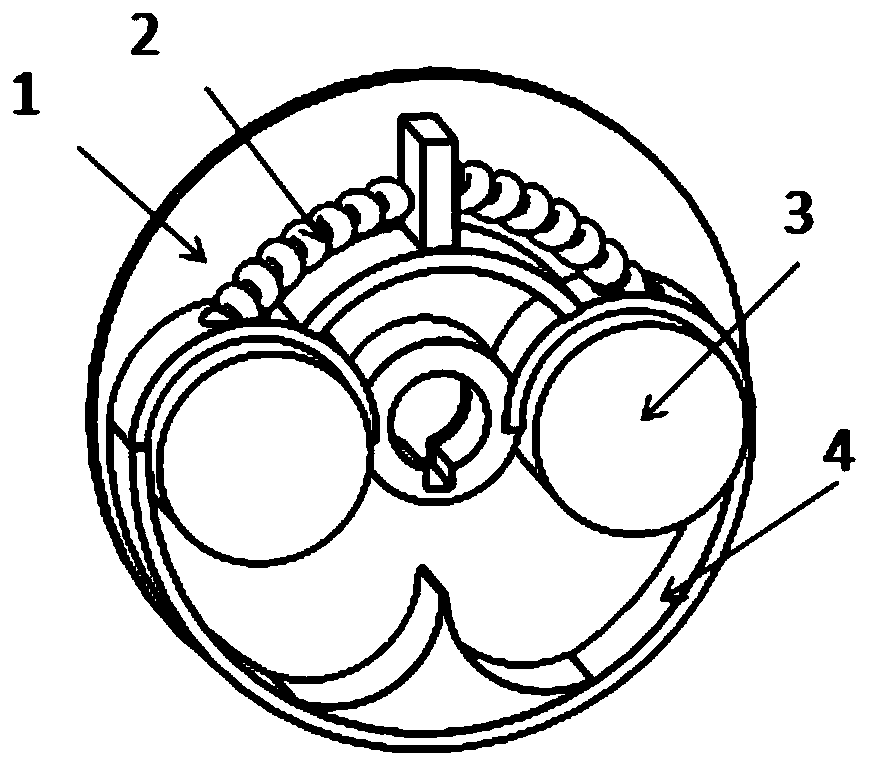

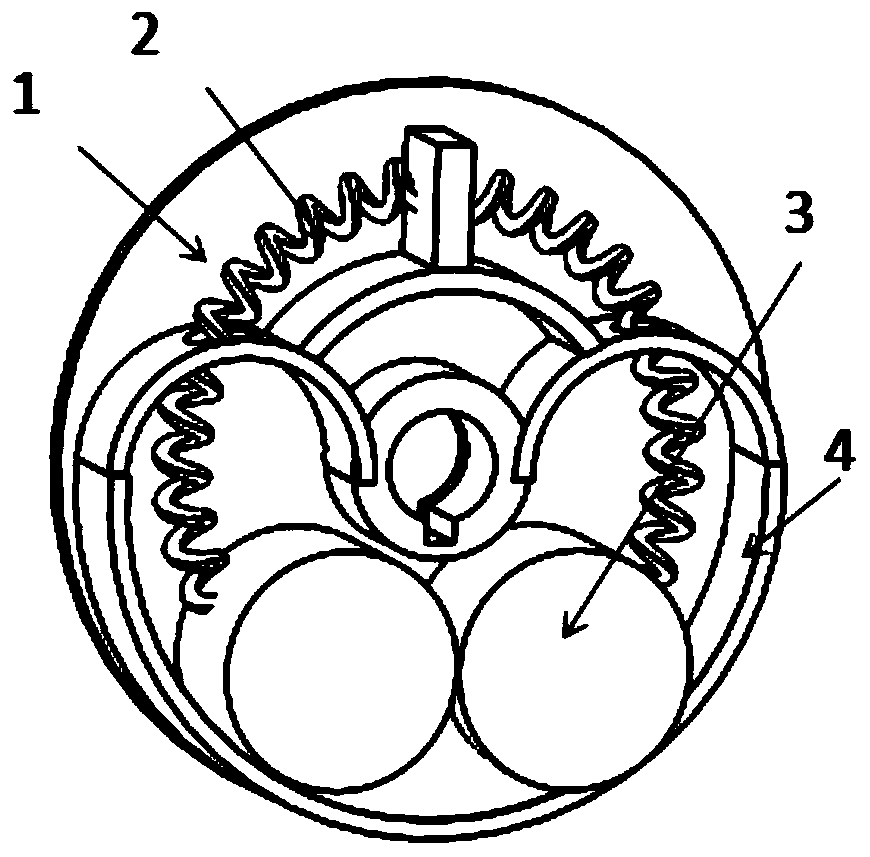

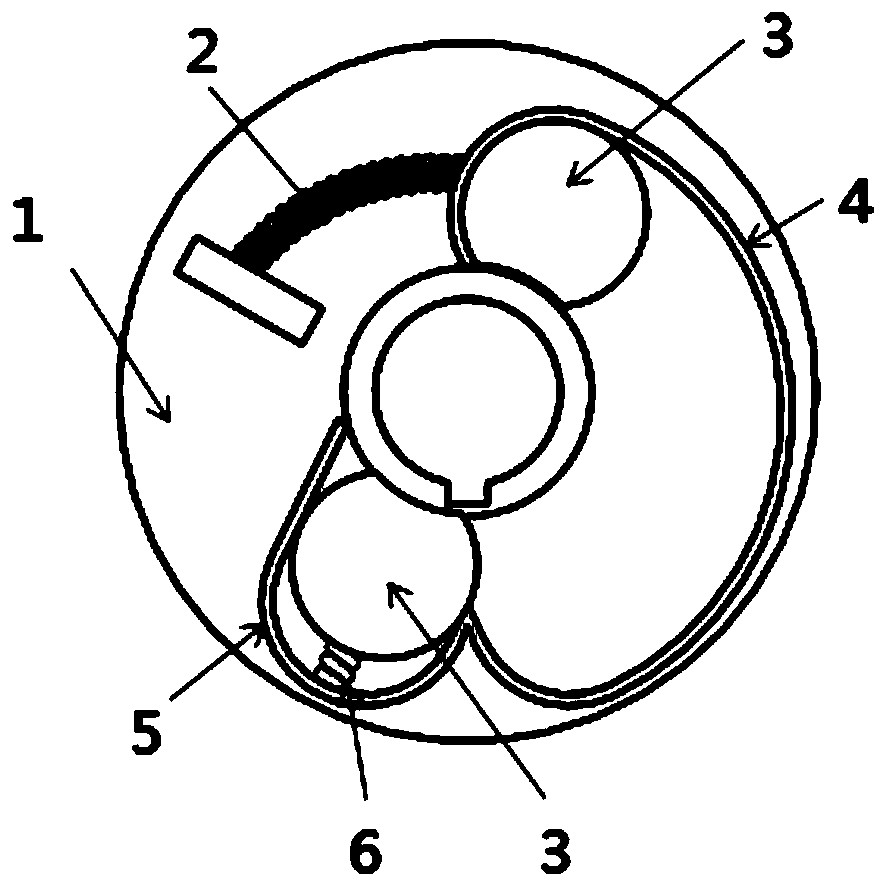

[0044] figure 1 It is a static schematic diagram of the first embodiment of the eccentric mass of the present invention. figure 1 Among them, two involute-like rails 4 are symmetrically opened on the eccentric block chassis 1, and the involute-like rails 4 are divided into at least three sections, including a semicircular orbit near the center of the axis, which serves as the near-center positioning of the live counterweight 3 The track includes the involute-like outer track as the moving track of the living counterweight 3, the semicircular track at the far-axis position, the telecentric positioning track of the living counterweight 3, and the inner track. A live counterweight 3 is arranged in each involute-like track 4, and a spring fixing sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com