Punching and blanking equipment modified based on layout scheme and operation method thereof

A blanking and equipment technology, applied in the field of stamping technology, can solve the problems of low material utilization, cost impact, and cost rise, and achieve the effects of convenient operation, cost saving, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

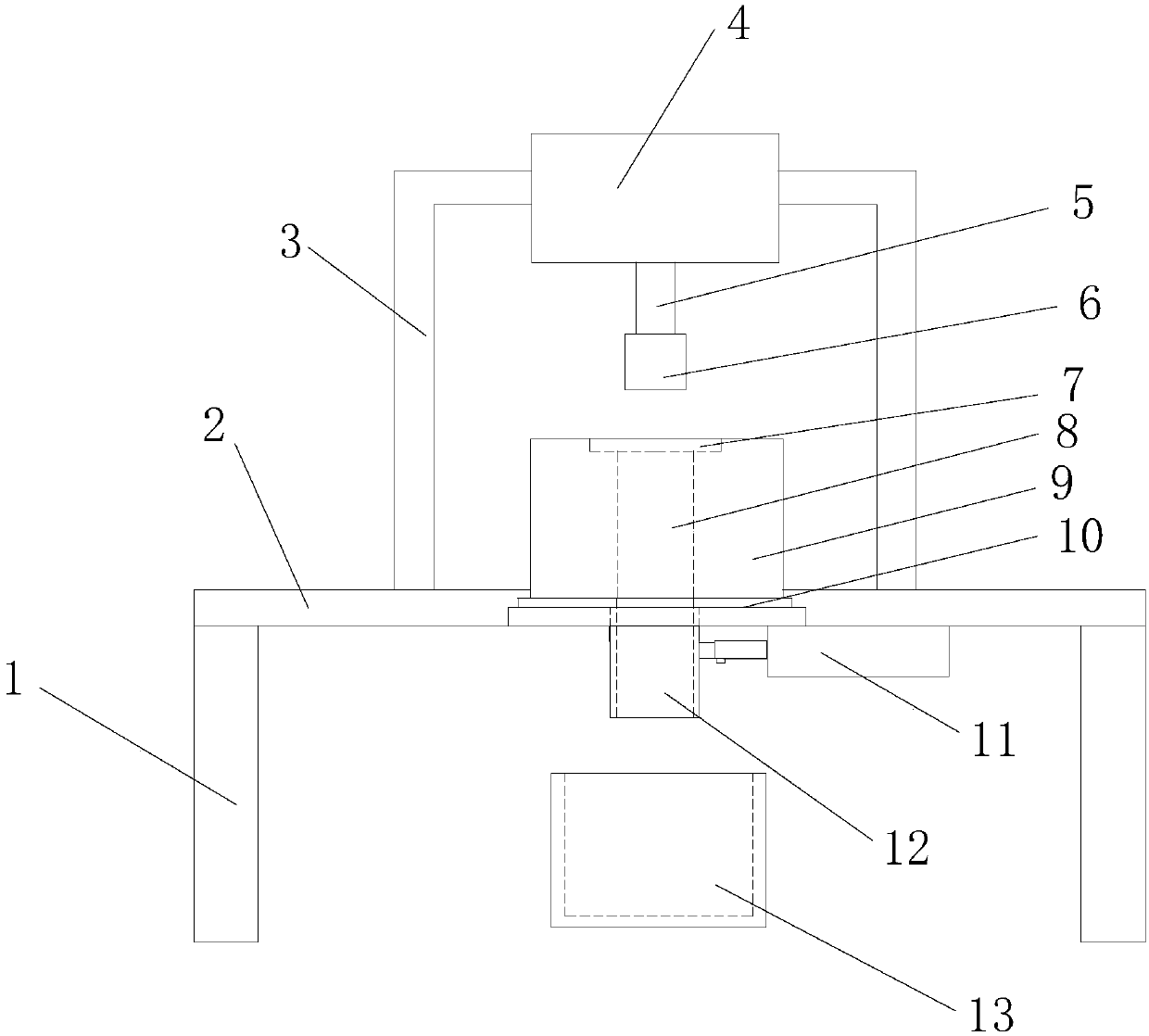

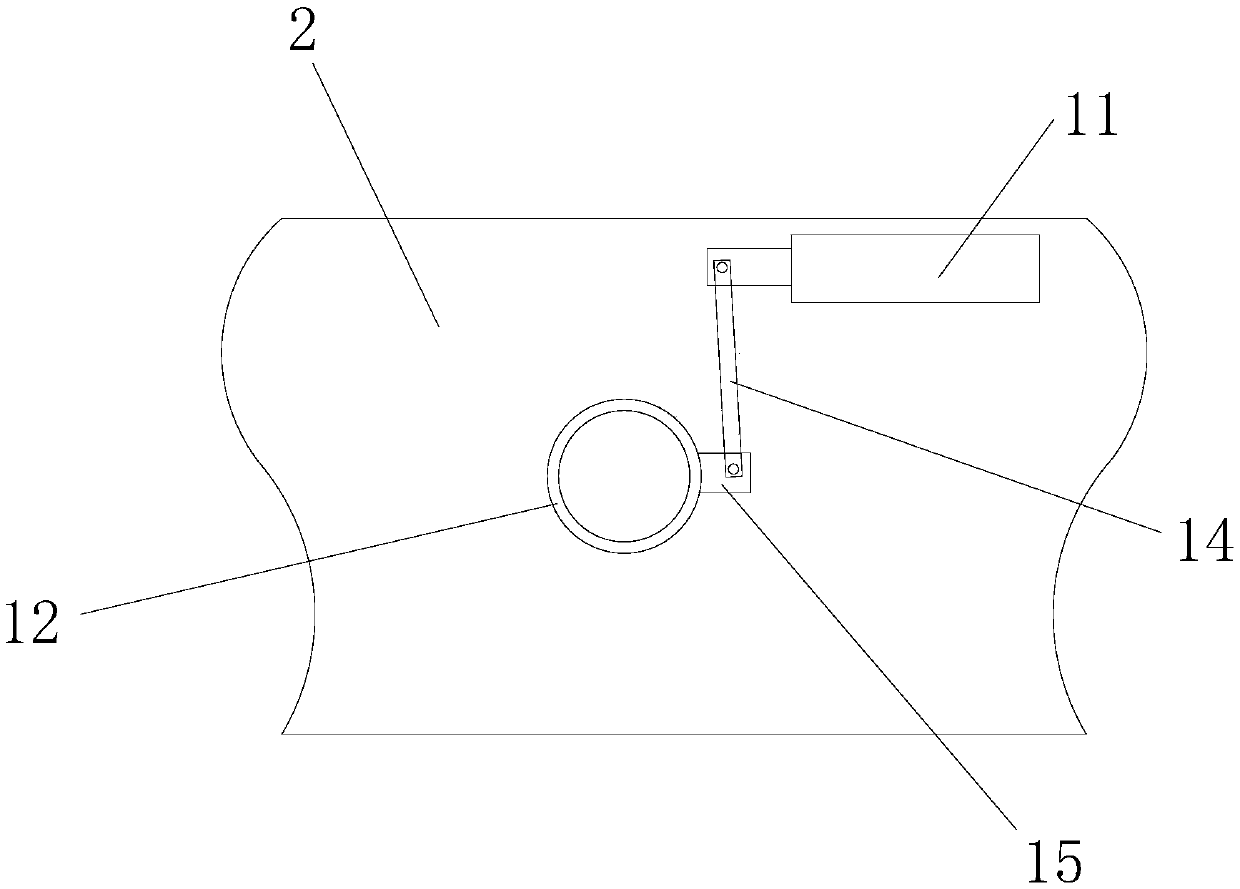

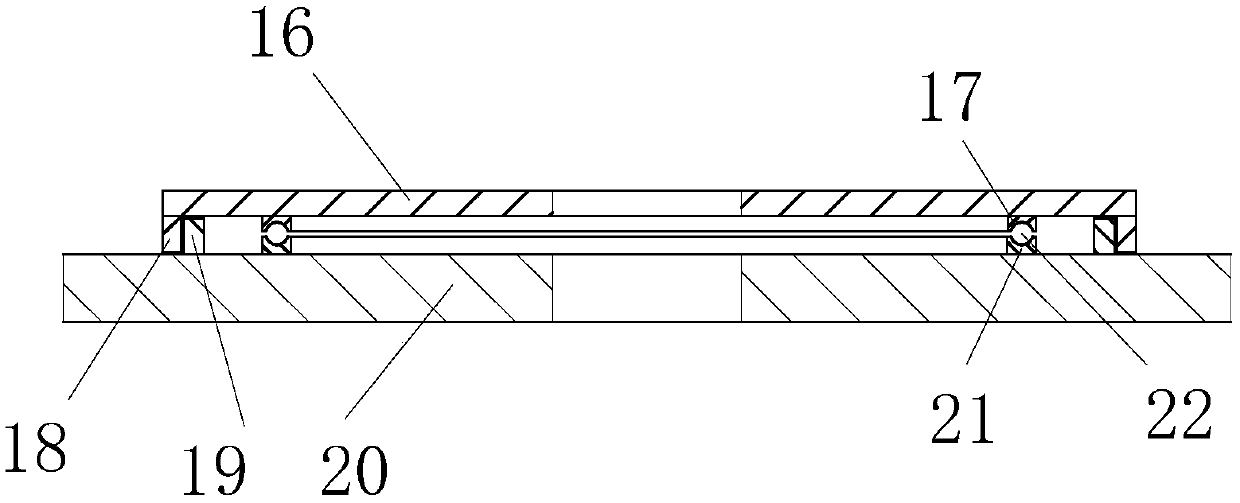

[0026] Such as figure 1 , 2As shown in , 5 and 6, a stamping and blanking equipment modified based on the layout plan includes a workbench 2, the bottom of the workbench 2 is provided with an outrigger 1, and the workbench 2 is supported on the ground by the outrigger 1, and the workbench 2 is fixed with a press 4 through a bracket 3, and the punch 5 of the press 4 is connected with a blanking punch 6, which can drive the blanking punch 6 to move through the press 4, and the corresponding blanking punch 6 on the workbench 2 A blanking die 9 is provided, and the blanking die 6 cooperates with the blanking die 9 to punch out a blanking part with a certain shape and size. The upper surface of the blanking die 9 is provided with a The discharge groove 7 of the processed blank 24, the blank 24 is placed in the discharge groove 7, can prevent the blank 24 from moving during the operation, the bottom of the blanking die 9 is connected with a rotating device 10, and the blanking die ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com