Automatic wooden handle tip planing machine

A technology of automatic turning and cutting machine, which is applied in the direction of woodworking lathes, wood processing equipment, manufacturing tools, etc. It can solve the problems of increasing labor intensity of workers, error of cutting length, and rising of defective products, so as to avoid the trouble of cutting materials for workers , reduce the workload, and ensure the effect of smooth use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

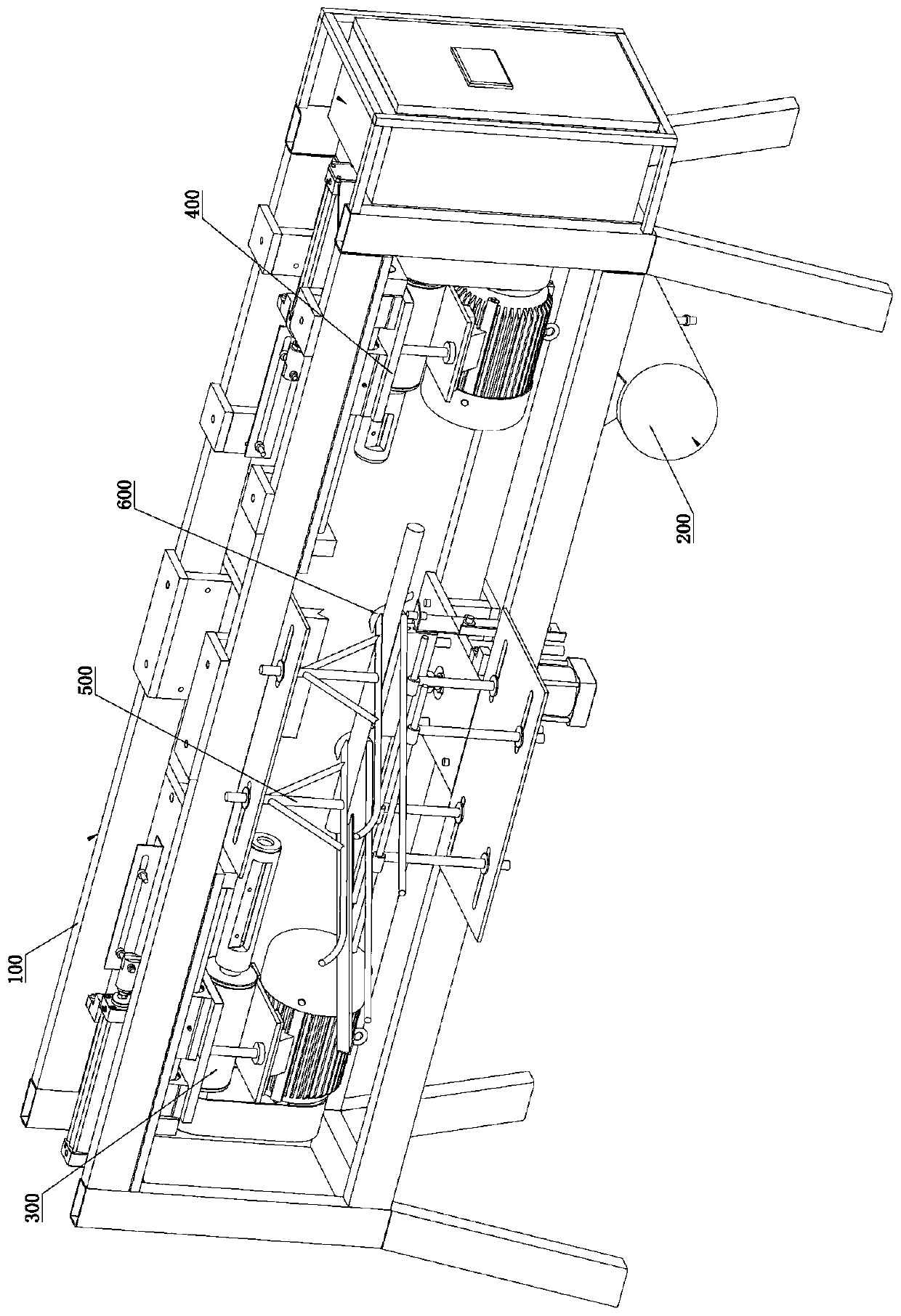

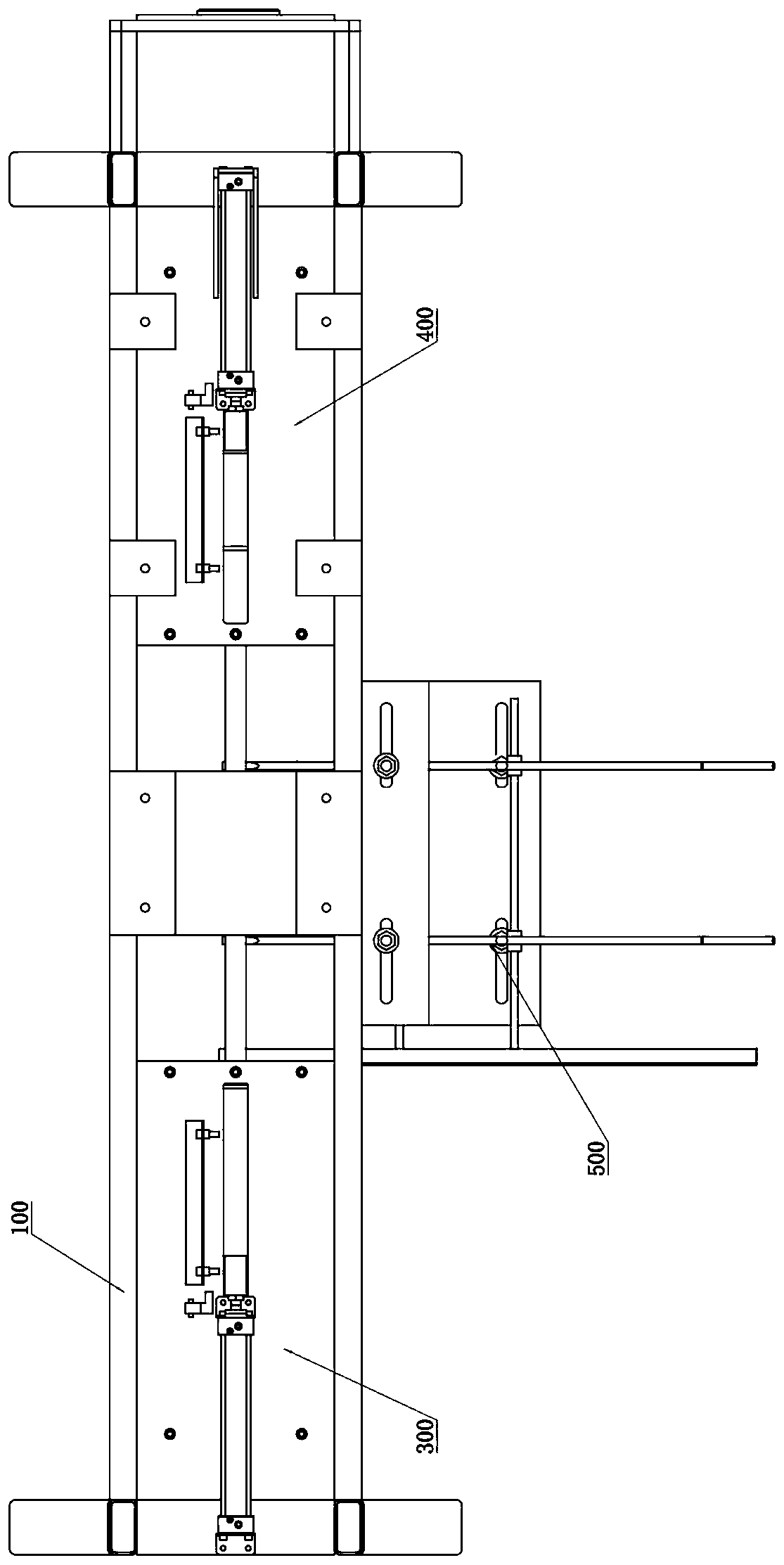

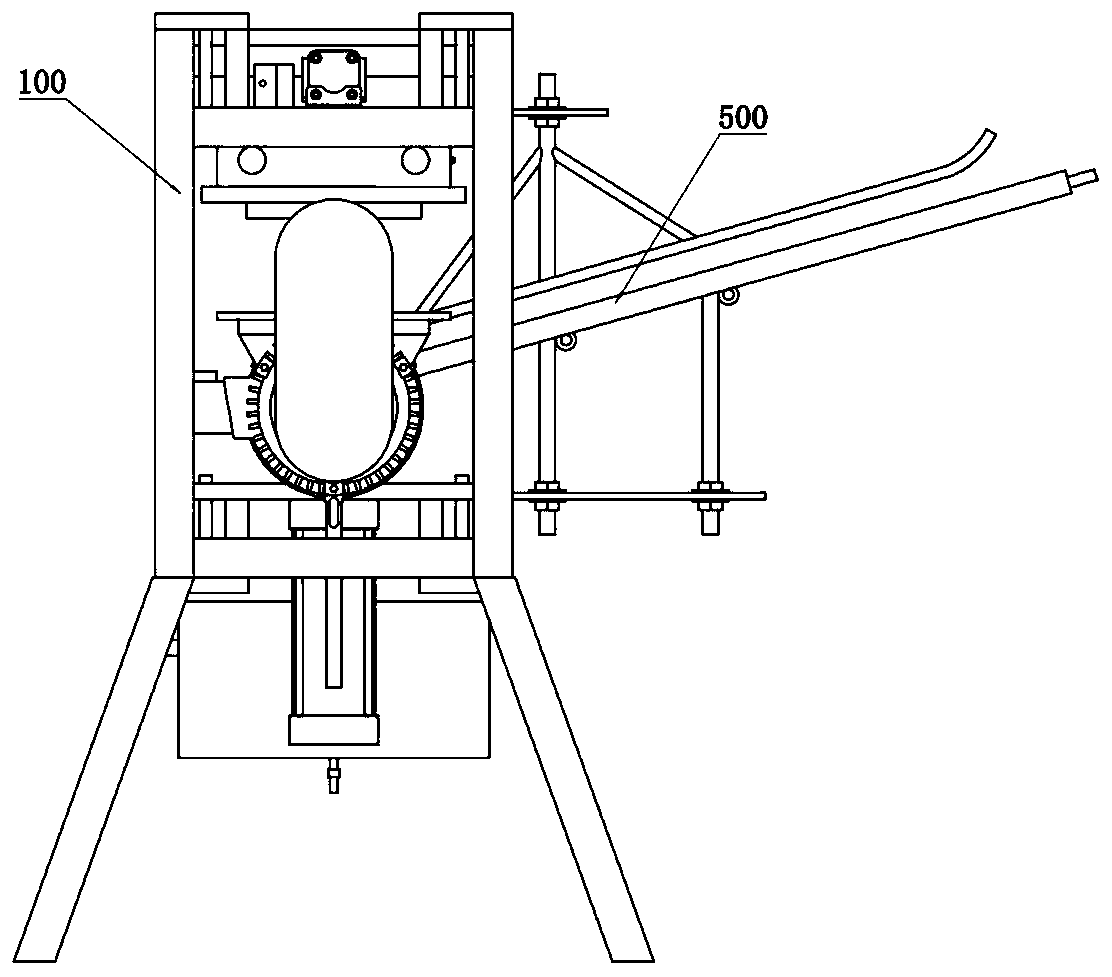

[0026] Such as Figure 1 to Figure 3 As shown, this specific embodiment adopts the following technical solutions: a wooden pole automatic turning machine, including a main body frame 100, an air storage tank 200, a turning part 300, a car shell part 400, a clamp part 500 and a stripping part 600; The lower right side of the main body frame 100 is fixedly connected with an air storage tank 200; the tail part 300 is fixedly connected to the upper left side inside the main body frame 100; The shell part 400 is fixedly connected to the upper right side inside the main frame 100; the clamp part 500 is located in the center between the tip part 300 and the car shell part 400, and the clamp part 500 is fixedly connected to the center of the main frame 100; the stripper The part 600 is provided on the lower rear side of the jig part 500 .

[0027] Such as Figure 4As shown, the specific structure of the tip part 300 includes a motor-4, a transmission shaft-5, a tip planer 6, a shiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com