Assembly supporting floating body crossed splicing type water surface photovoltaic power generation system

A photovoltaic power generation system and support system technology, applied in the photovoltaic field, can solve the problems of difficulty in forming a floating water surface photovoltaic overall power generation scheme, difficulty in ensuring the stability and safety of the power station, and inability to provide electrical equipment support, etc., so as to save aisle floating body , The overall stability is excellent, the effect of reducing the shadow spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

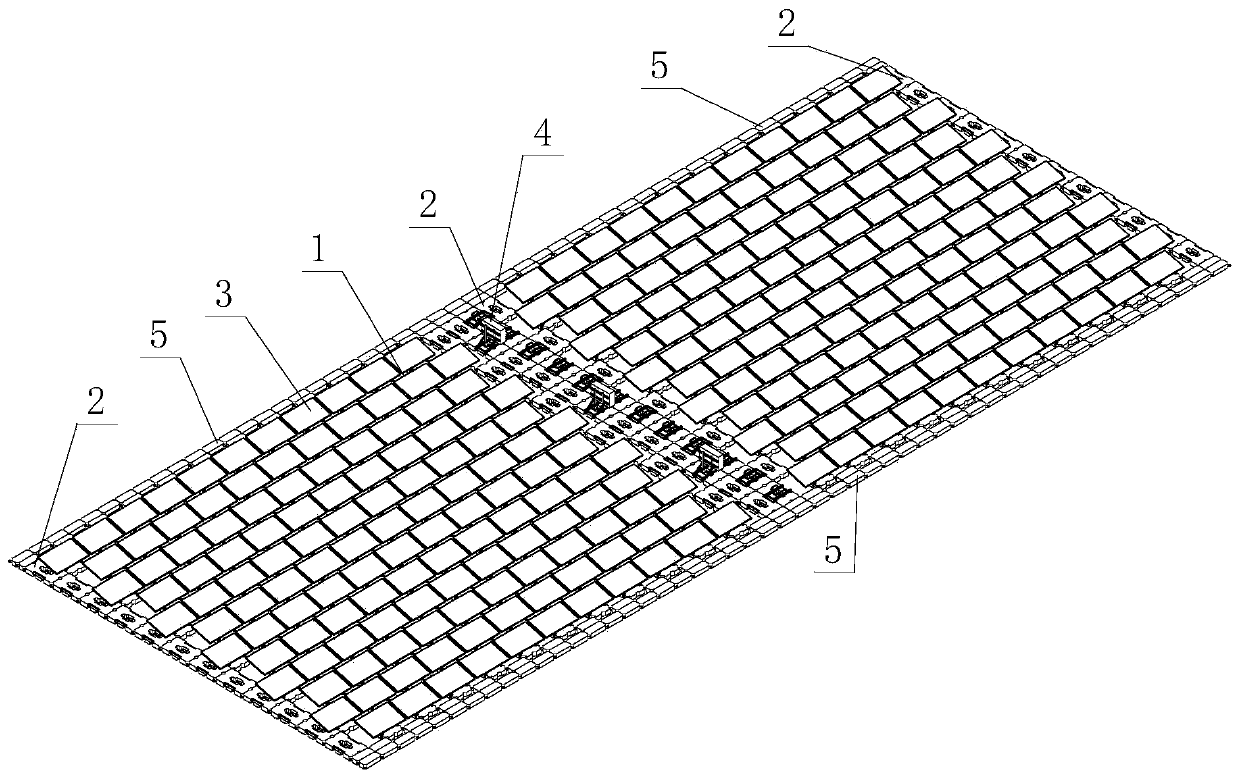

[0053] Such as figure 1 As shown, a component-supported floating body cross-splicing water surface photovoltaic power generation system of the present invention includes a component-supported floating body device and an equipment floating body device. The component-supported floating body device is used to install and support photovoltaic modules 3, and electrical equipment 4, cables and anchoring systems are fixed Installed on the equipment floating body device; the component support floating body device and the equipment floating body device are spliced together.

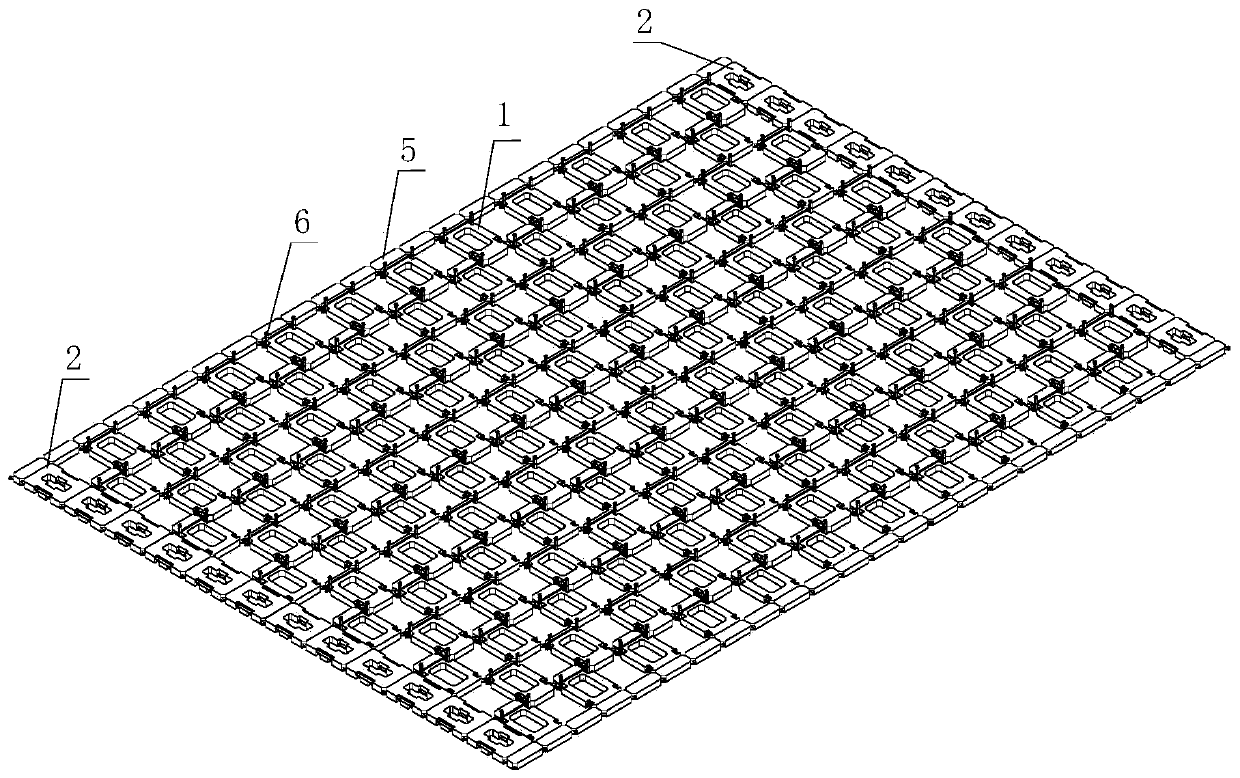

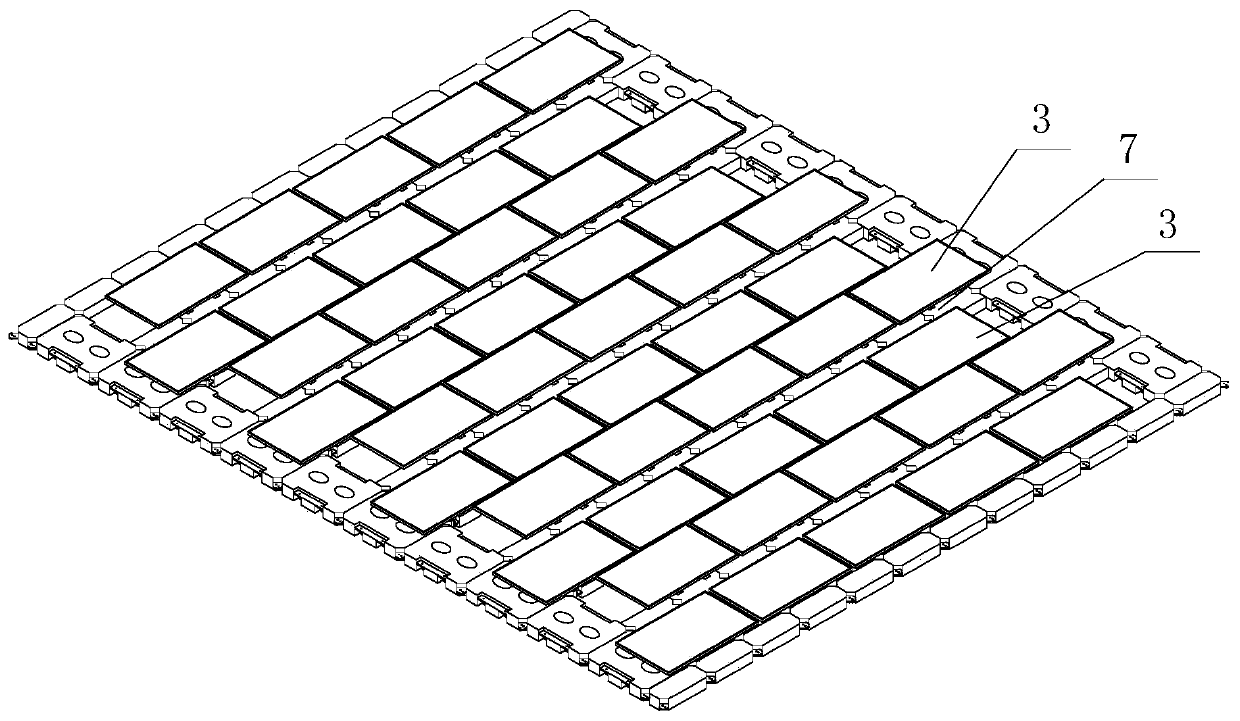

[0054] Such as Figure 2-4 As shown, in this embodiment, the module supporting floating body device includes multiple rows of module supporting floating bodies 1 that are spliced together crosswise, and each row of module supporting floating bodies 1 includes a plurality of mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com