Unmanned-aerial-vehicle-and-oblique-photography-camera-combined aircraft-body upper surface checking method

A technology of oblique photography and aircraft fuselage, applied in the direction of aircraft component testing, etc., can solve the problems of time delay and manpower consumption, manpower and time consumption, and poor versatility, and achieve the goal of improving efficiency, strong versatility, and significant economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

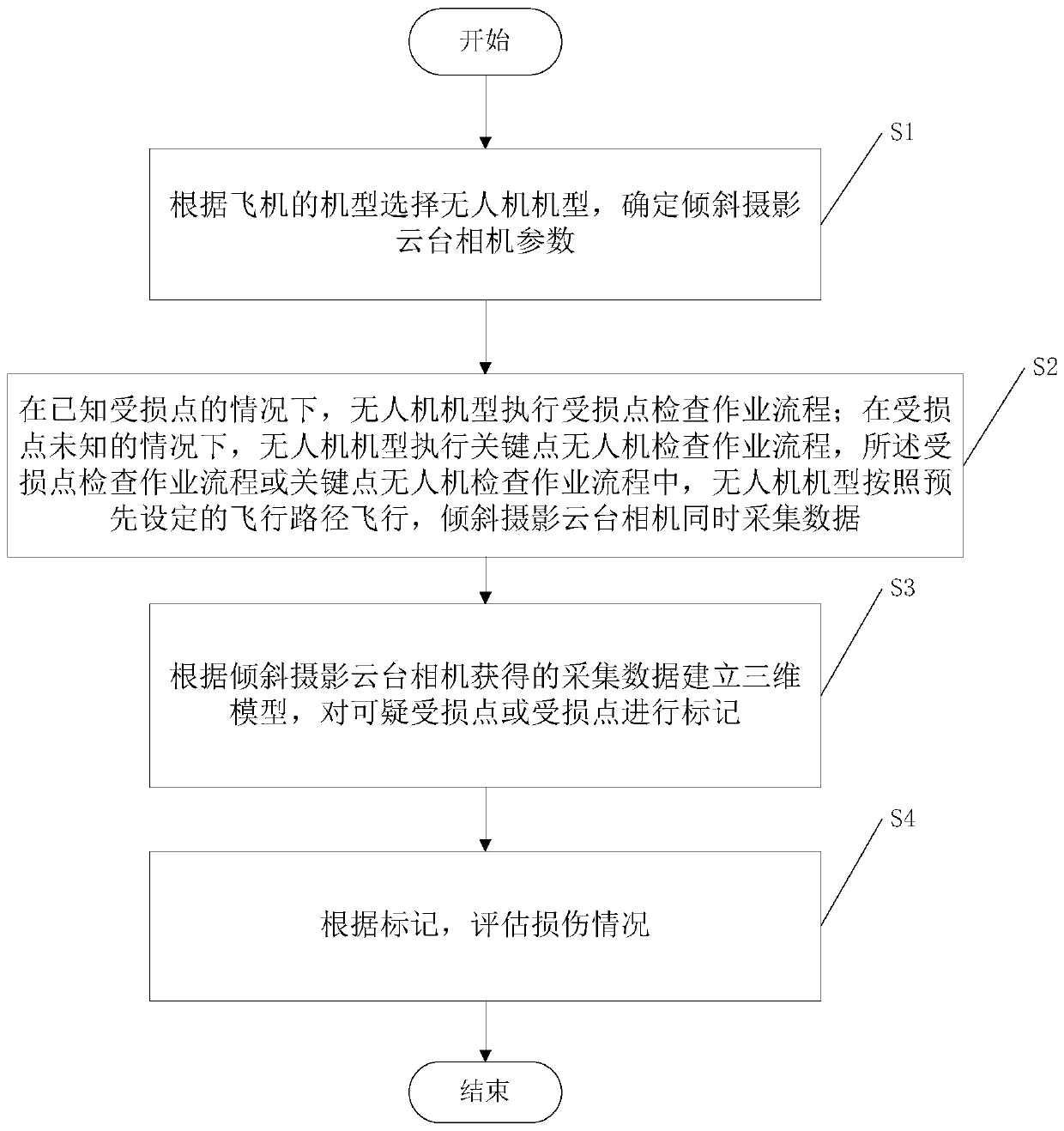

[0048] A method for inspecting the upper surface of an aircraft fuselage combined with an unmanned aerial vehicle tilting camera. The scope of inspection involves the upper half of the line between the nose and the center line of the wing and the three points of the tail, the wing, and the tail. The flow chart is as follows figure 1 shown, including the following steps:

[0049] S1, select the UAV model according to the model of the aircraft, and determine the camera parameters of the tilt photography pan / tilt.

[0050] The length of the wingspan and the length of the aircraft will directly affect the path length of the UAV operation. The longer the path length is, the larger the battery capacity of the UAV is required. Estimate the flight distance of the UAV, so as to estimate the minimum value of the battery capacity of the UAV. Considering the cost, when the battery capacity of the UAV model is greater than or equal to the minimum value of the battery capacity, it is consid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com