Automatic grain storage equipment

An equipment and grain technology, applied in the field of equipment that can automate grain storage, can solve the problems of damage, grain pollution, and high grain storage costs, and achieve the effects of less wear, energy saving, and grain storage costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

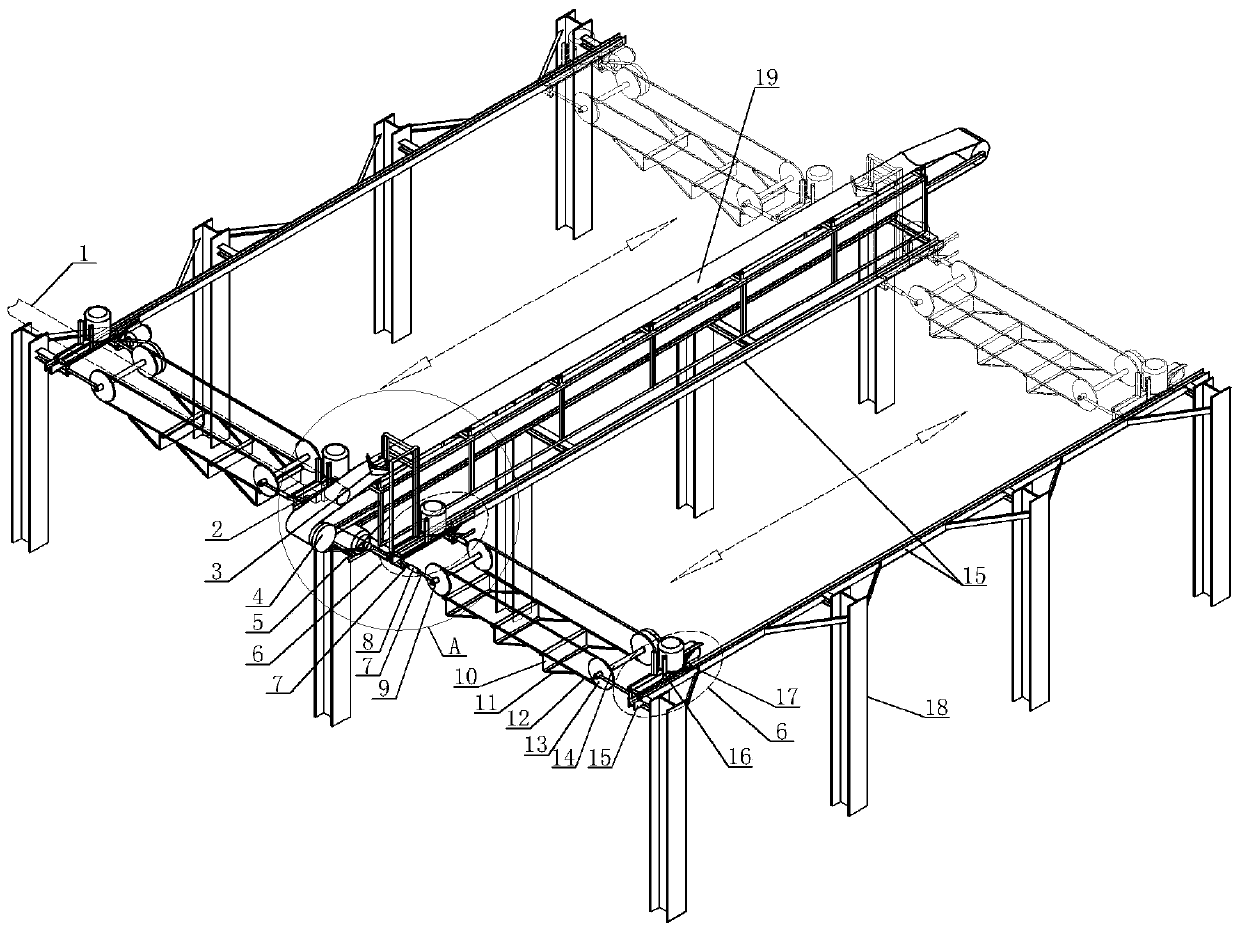

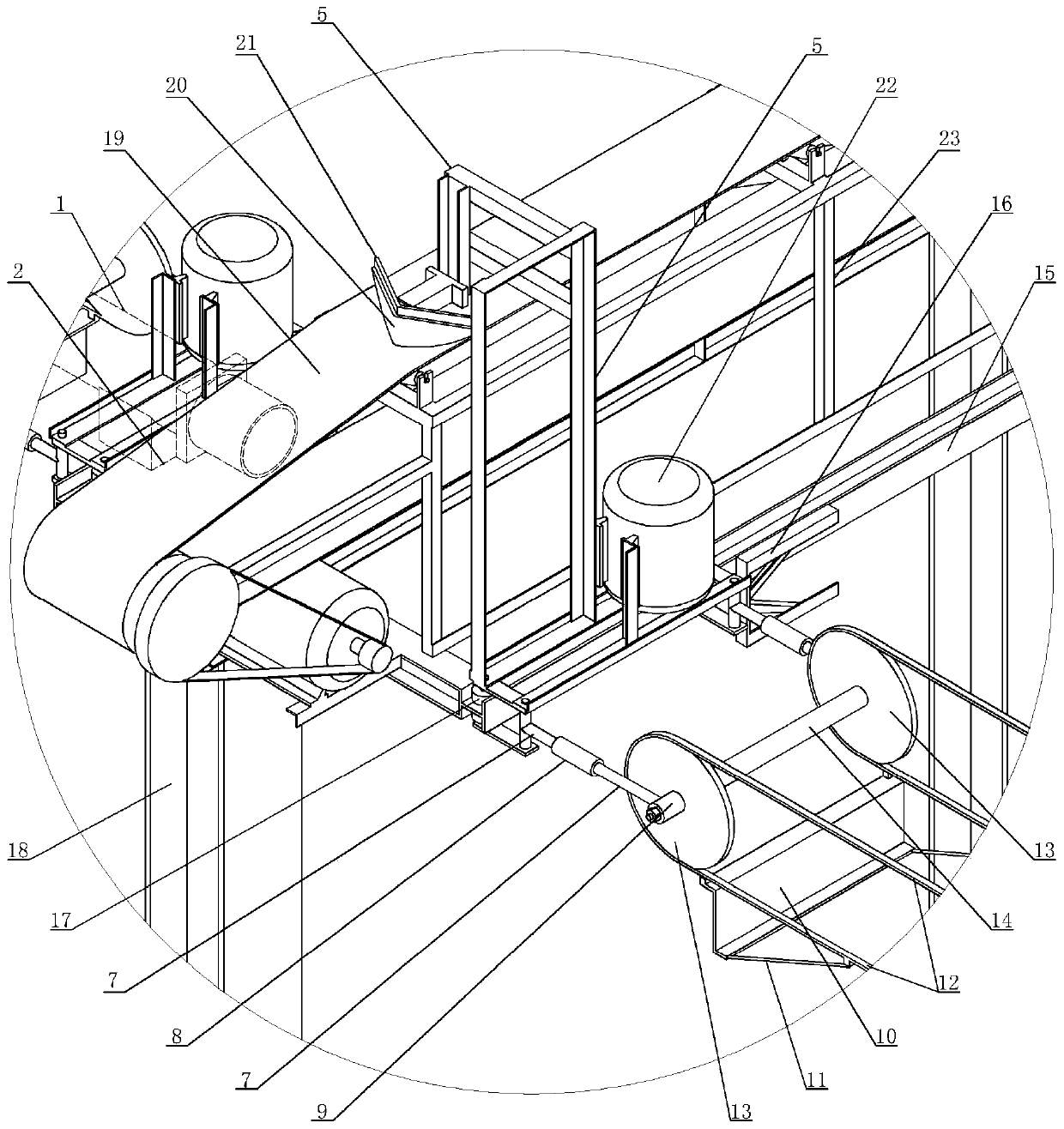

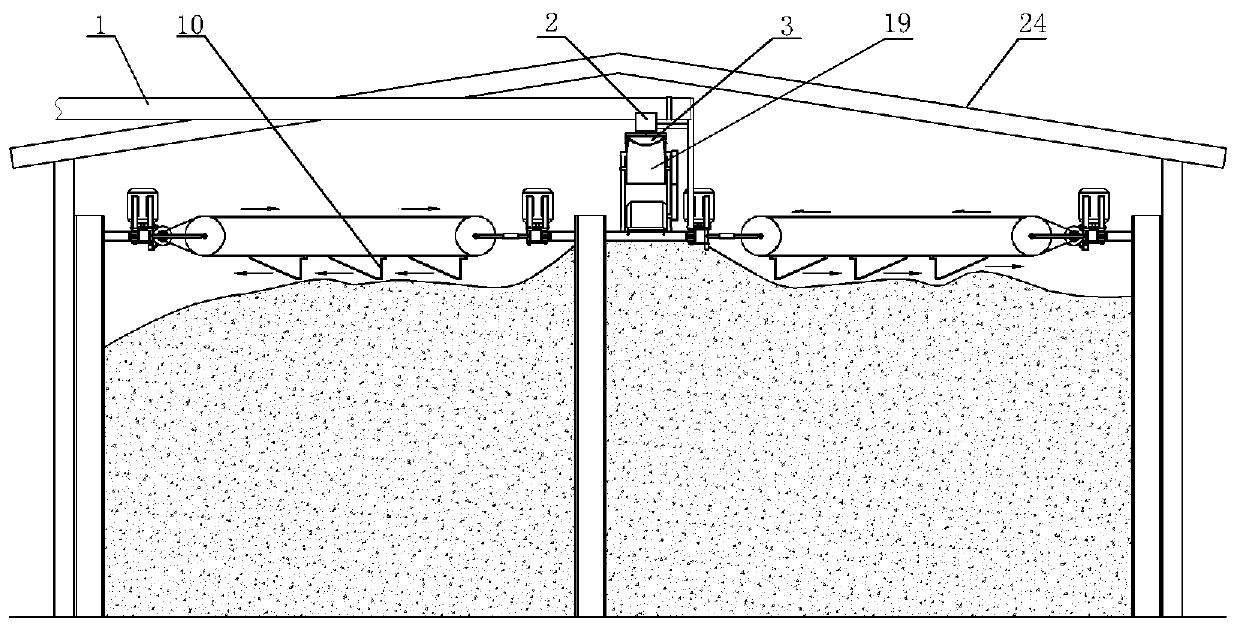

[0028] Automated grain storage equipment, such as figure 1 and figure 2 Shown structure, it has belt conveyor 4, raking grain mechanism, inclined scraper 3; Described raking grain mechanism has two tracks 15, and two tracks are arranged in parallel with the conveyor belt 19 of belt conveyor, and two tracks Each is equipped with a power rail car 6, and the vehicle frame 16 of each power rail car walks on the corresponding track through the track wheel 17. Two sprocket shafts 14 are arranged between the two tracks, and one of the sprocket shafts is connected to one of the power rails in rotation. On the frame of the rail car, another sprocket shaft is rotatably connected to the frame of another power rail car. One of the sprocket shafts is a power shaft. The two ends of the two sprocket shafts are respectively fixed with sprocket wheels 13, and the two chains The two sprockets on the same side of the wheel shaft are linked by a chain 12, and a plurality of grain raking plates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com