Automatic falling device of wine bottle bracket

A rack device and bracket technology, which is applied in the field of automatic cutting, can solve the problems of time-consuming, labor-intensive and low-efficiency, and achieve the effects of noise reduction, high efficiency and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] After the produced wine bottle brackets are transported out, the wine bottle brackets need to be manually rearranged before returning to the spraying room for the next batch of spraying, which is time-consuming and laborious, and the efficiency is low. Therefore, it is necessary to provide a device capable of automatically sorting and collecting wine bottle brackets to improve production efficiency.

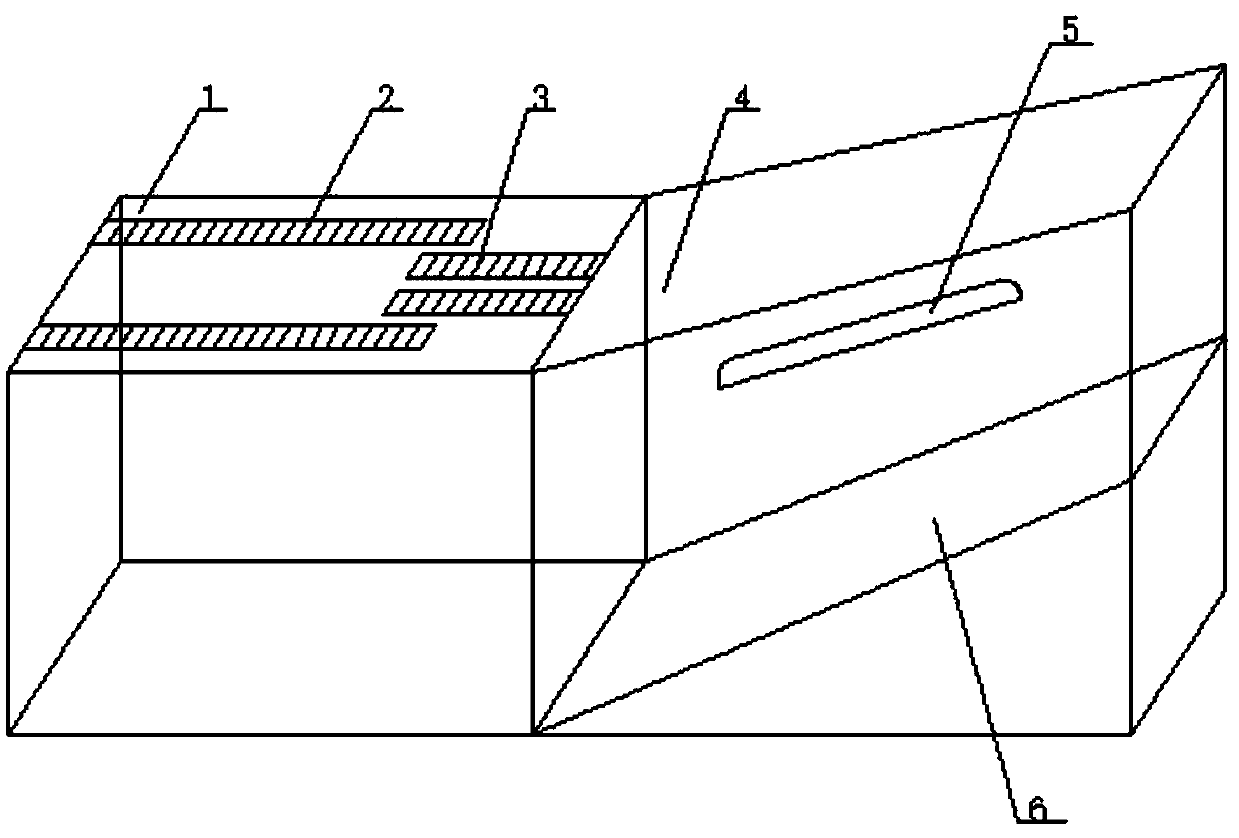

[0026] In order to solve the above technical problems, the present invention provides an automatic unloading device for wine bottle brackets. refer to figure 2 As shown, the automatic unloading device of the wine bottle bracket includes a transfer box 1 and a pick-up box 4, the pick-up box 4 is connected to the transfer box 1 at an angle, and the connecting end of the pick-up box 4 Lower than the non-connecting end; the transmission box 1 is provided with a first transmission assembly and a second transmission assembly that move in the same direction and can be adjusted ...

Embodiment 2

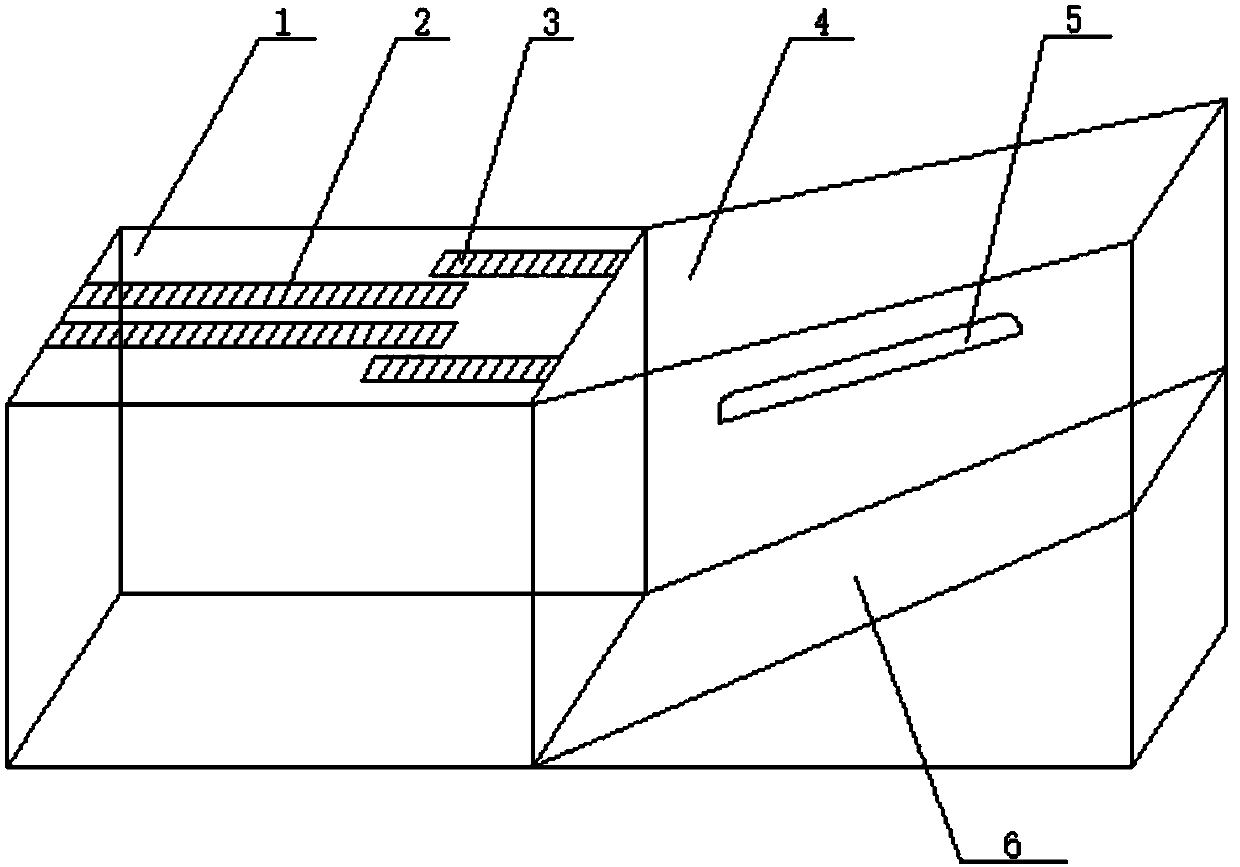

[0035] refer to image 3 As shown, different from Embodiment 1, this embodiment provides an installation diagram of another mutual positional relationship between the first transmission assembly and the second transmission assembly, and the second transmission chain 3 is arranged on the first The outside of the transmission chain 2.

Embodiment 3

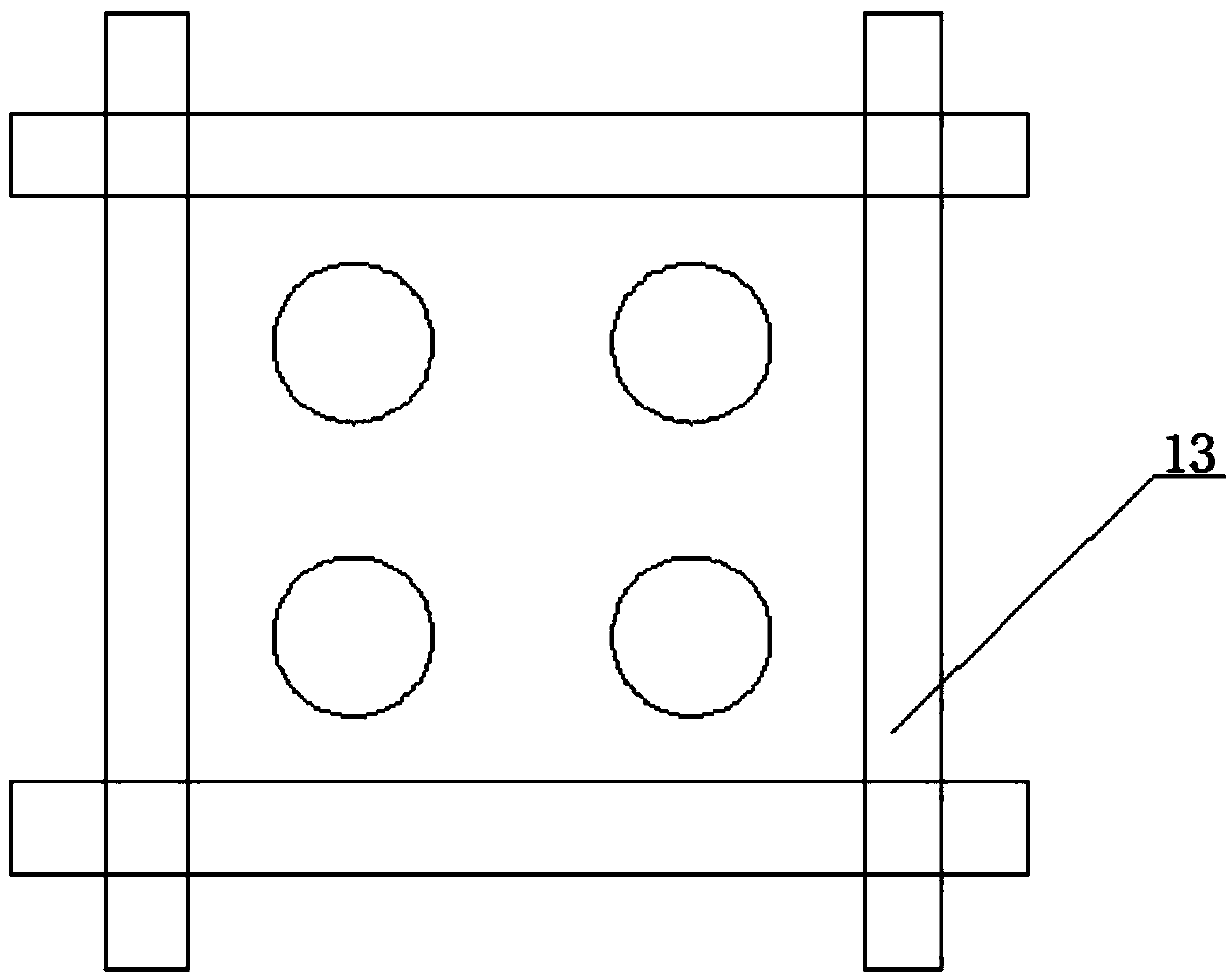

[0037] The difference between this embodiment and Embodiment 1 is that this embodiment provides another connection method between the receiving guide rail 5 and the receiving box 4, refer to Figure 5 As shown, the receiving guide rail 5 includes a connection side wing and a support frame 9, the support frame 9 is welded on the connection side wing, and the connection side wing includes a first side wing 7 and a second side wing that are symmetrically arranged relative to the support frame 9. Two side wings 10, the first side wing 7 and the second side wing 10 respectively have through holes 8. The same through hole is also arranged on the said receiving box 4, and the through hole 8 on the said first side wing 7 and the second side wing 10 is passed through the screw to cooperate with the through hole on the said receiving box 4, and the said receiving box 4 The receiving guide rail 5 is fixed on the receiving box 4 . The receiving guide rail 5 can slide on the through hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com