Adhesive composition

A composition and adhesion technology, applied in the directions of adhesive additives, conductive adhesives, non-polymer adhesive additives, etc., can solve the problems of the decrease of the adhesion between the conductive carbon film and the substrate, and the peeling of the conductive carbon film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

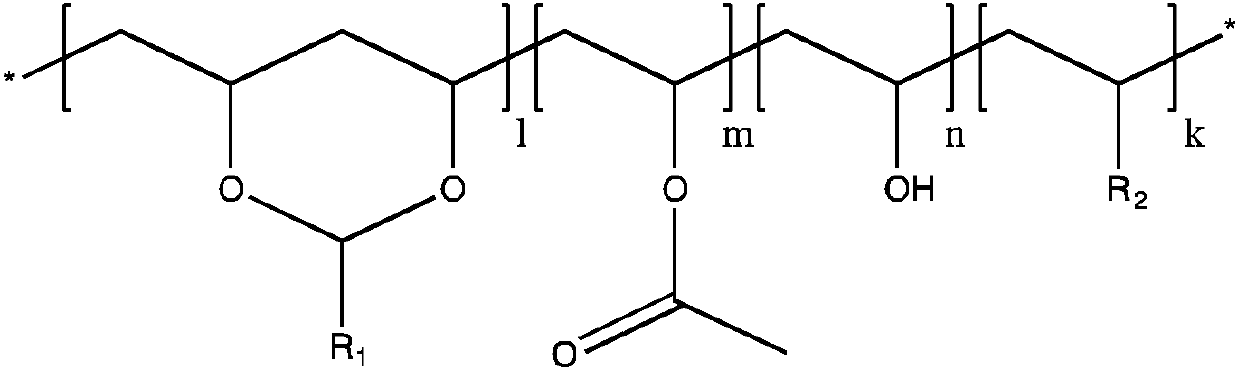

Method used

Image

Examples

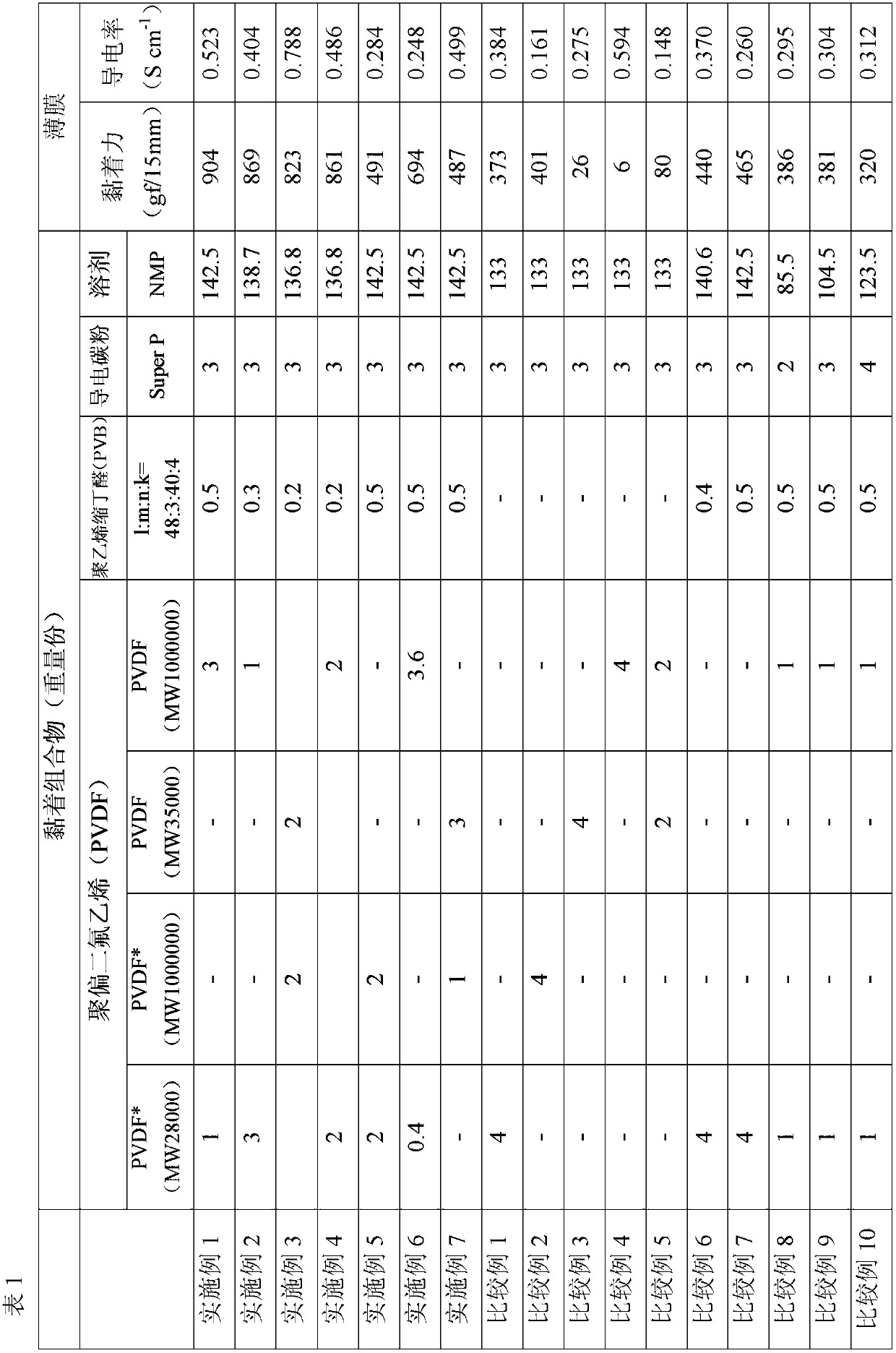

Embodiment 1~7 and comparative example 1~10

[0029] Preparation of Adhesive Compositions - Tests of Different Component Ratio

[0030] According to the weight ratio shown in Table 1, PVDF* (MW28000) with carboxyl group, PVDF* (MW1000000) with carboxyl group, PVDF (MW35000) without carboxyl group, PVDF (MW1000000) without carboxyl group, PVB (MW100000; purchased from Sekisui Chemical), conductive carbon powder (Super P; purchased from Timcal) were added to the solvent N-methylpyrrolidone (NMP), mixed and fully stirred at room temperature (about 25°C) to form an adhesive with a solid content of 5%. combination.

[0031] Film preparation

[0032] The adhesive compositions obtained in Examples 1-7 and Comparative Examples 1-10 were coated on an aluminum foil substrate having a thickness of 20 μm using a wire bar. Next, drying treatment was carried out at 110° C. for 30 minutes to obtain a film with a thickness of about 1 μm.

[0033] Next, the adhesion test between the film and the substrate and the conductivity test of t...

Embodiment 5

[0039] The adhesive composition of Example 5 includes two kinds of PVDF with different weight average molecular weights, wherein the PVDF used both have carboxyl groups, and the adhesive composition also includes PVB. In Example 5, the weight of PVDF* having a carboxyl group accounted for 100% of the weight of the entire PVDF. It can be seen from the results in Table 1 that the adhesive force of the formed film is good.

Embodiment 6

[0040] The adhesive composition of Example 6 includes two PVDFs with different weight average molecular weights, one of the used PVDFs has carboxyl groups, and PVB is also included in the adhesive composition. In Example 6, the weight of PVDF* having carboxyl groups accounted for only 10% by weight of the total PVDF. It can be seen from the results in Table 1 that the adhesive force of the formed film is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap