Non-destructive dismantling method of negative ring segments after shield machine passes through intermediate air shaft

A negative ring segment and shield machine technology, which is applied in wellbore lining, shaft equipment, earth-moving drilling, etc., can solve the problems of low demolition efficiency, small demolition space, and segment damage, so as to improve demolition efficiency and ensure personal safety. Safety and the effect of reducing the breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in combination with specific embodiments.

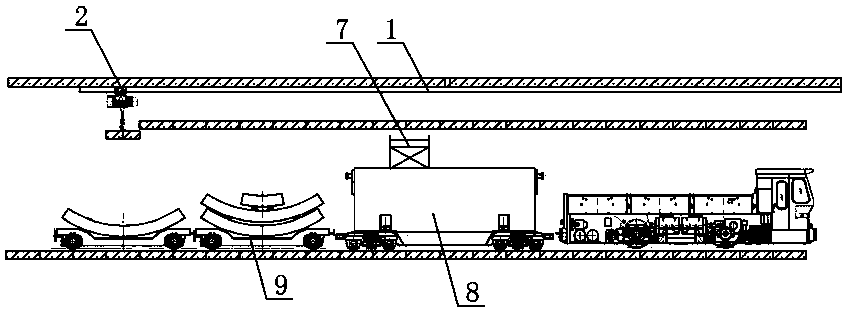

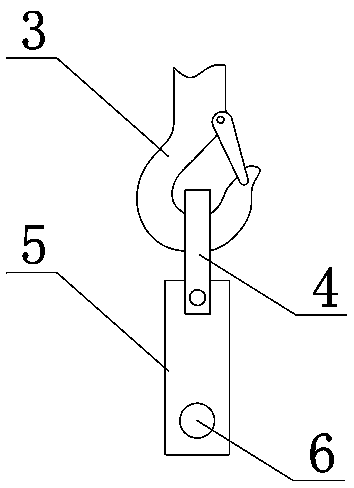

[0015] Such as figure 1 , figure 2 As shown, the present invention provides a special demolition hoist for negative ring segments, including a track 1 (the track 1 is I-shaped steel) fixedly connected to the middle plate of the wind shaft and an electric hoist 2 slidably arranged on the track 1. The hook 3 of the electric hoist 2 is hooked with a suspension ring assembly composed of a suspension ring 4 and a connecting steel plate 5. The lower part of the connecting steel plate 5 is provided with a mounting hole 6, and the segment to be removed can be removed by connecting the segment with the mounting hole 6 with bolts. The hook is hung on the electric hoist 2, and there is no need to repeatedly disassemble the suspension ring 4, which improves the dismantling efficiency.

[0016] The non-destructive removal method of the negative ring segment after the shield machine p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com