Component surface explosion load distribution rule analysis method

An analysis method and load distribution technology, applied in the direction of instruments, calculations, electrical digital data processing, etc., can solve problems such as failure to consider the coupling between explosion and structure, damage assessment work, and wrong research results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

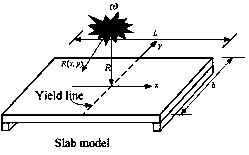

[0057] The present invention is described in conjunction with accompanying drawing and specific embodiment:

[0058] An analytical method for the distribution of explosive loads on the surface of a steel component, the specific steps of the analytical method are as follows:

[0059] 1) Firstly, calculate the peak pressure and forward impulse of the center of the blast surface; use the least squares curve fitting method to establish the fitting formula of the peak pressure of the regular reflection and the forward impulse; the fitting formula of the peak pressure of the regular reflection is:

[0060]

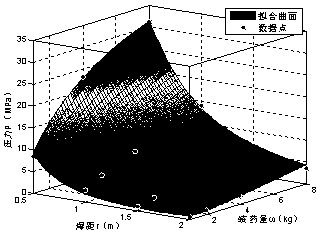

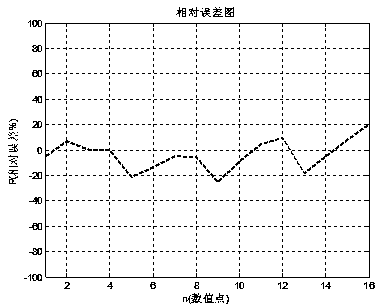

[0061] In the formula, P is the peak value of positive reflection overpressure, and the unit is MPa, r is the burst distance, the unit is m, Z is the proportional distance in m / kg 1 / 3 ; figure 2 The relationship between the peak pressure of the regular reflection, the charge and the detonation distance, and the relationship between the fitting surface and the numerical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com