A heat dissipation system of a full-frequency loudspeaker

A technology of a cooling system and a loudspeaker, applied in the field of loudspeakers, can solve the problems of poor heat dissipation, burnt out loudspeakers, and high loudspeaker temperature, and achieve the effects of accelerating the exchange of cold and hot air, increasing the radiation heat dissipation area, and improving the radiation heat dissipation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be further described in detail below. It should be understood that the description of the embodiments of the present invention here is not intended to limit the protection scope of the present invention.

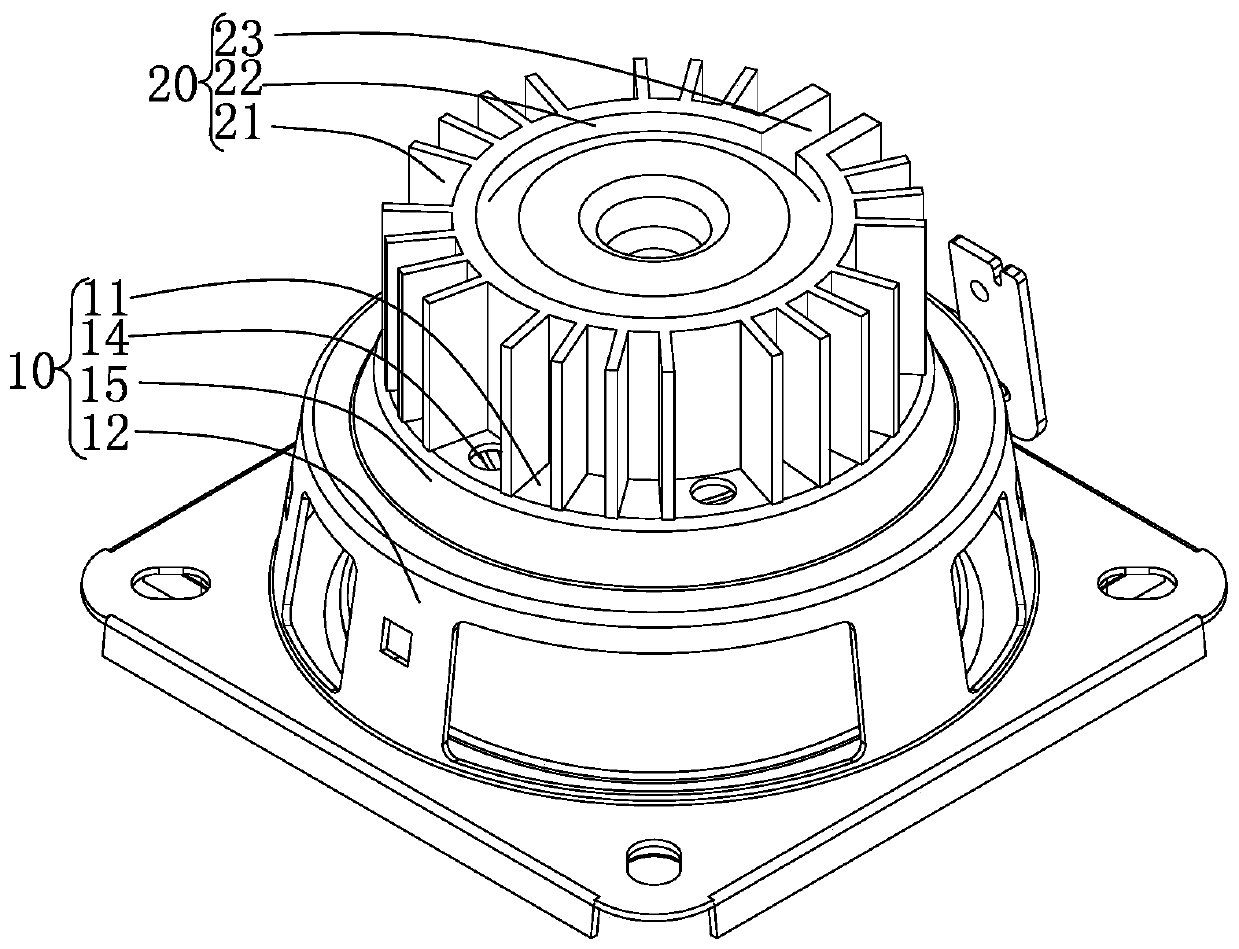

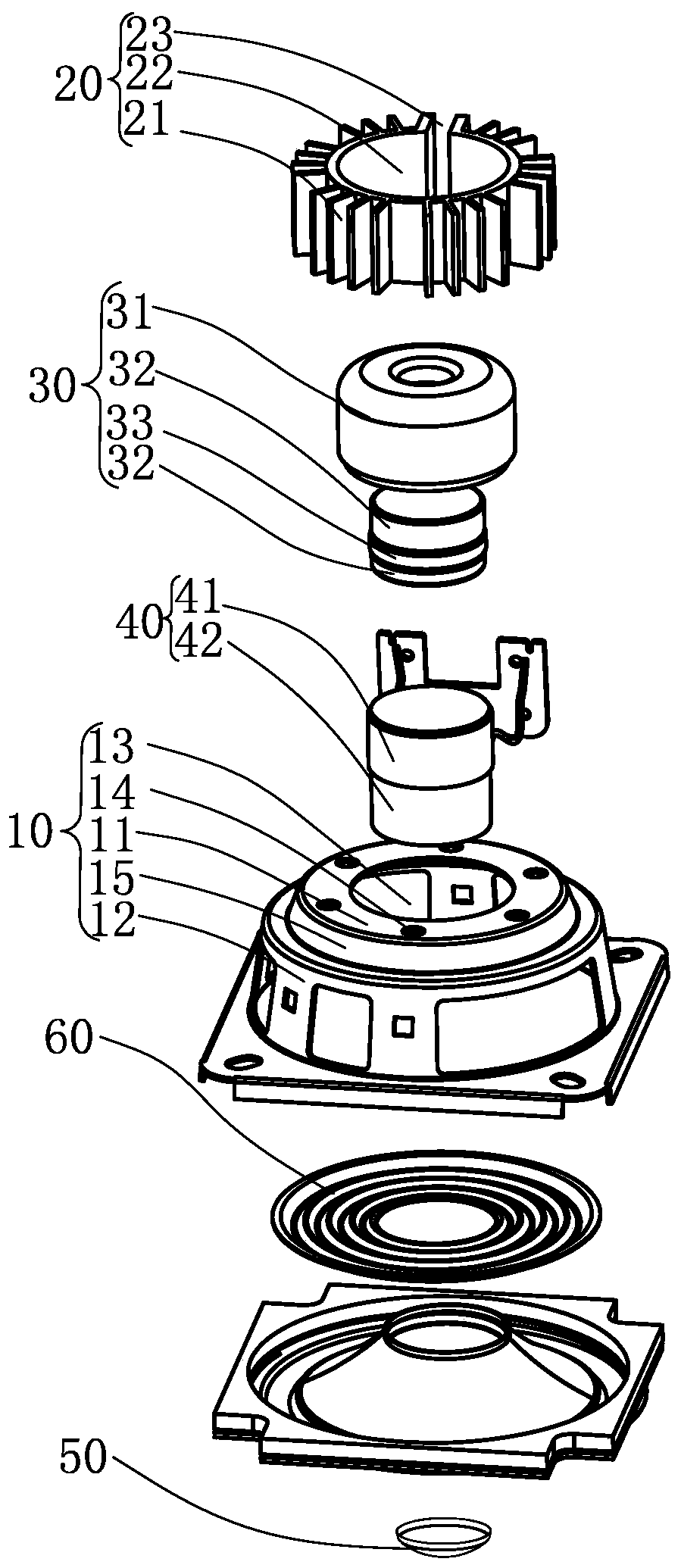

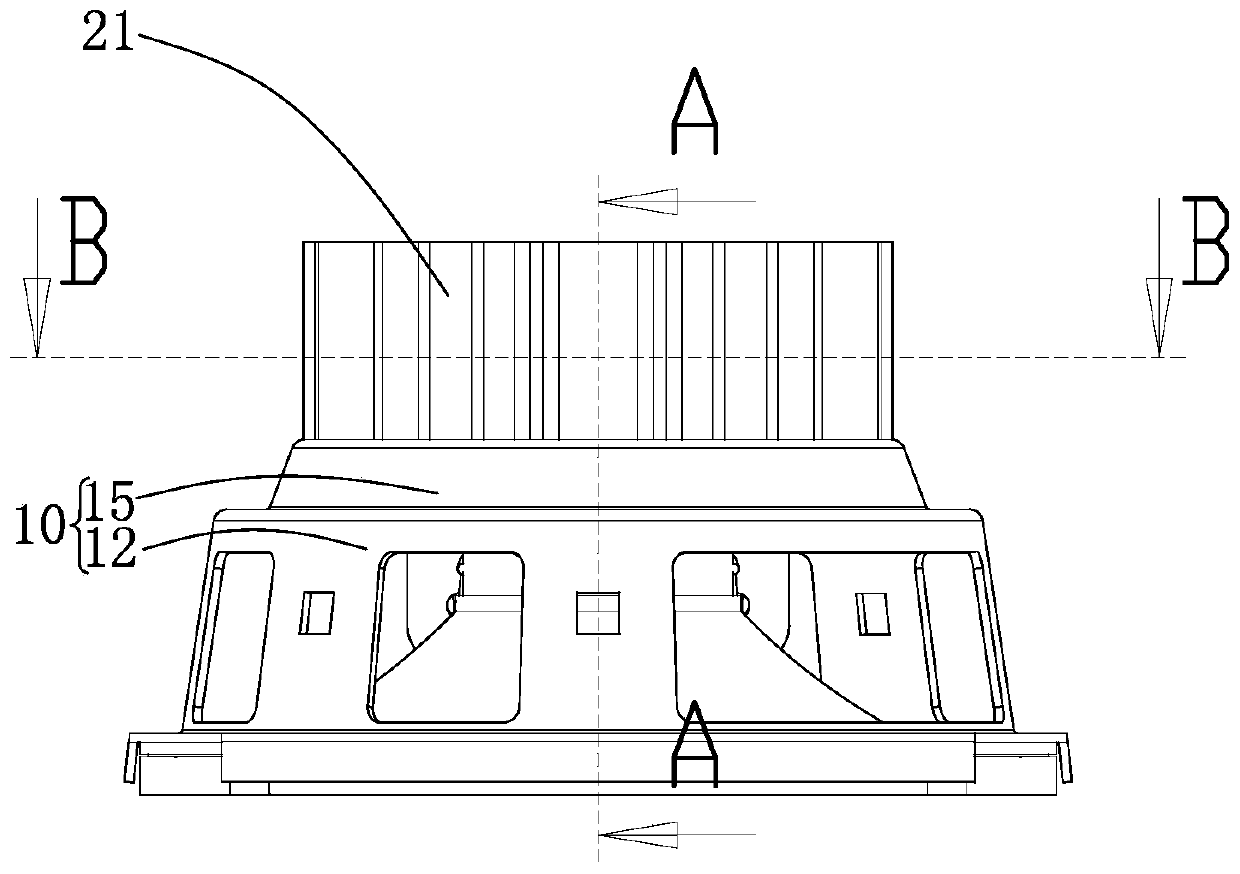

[0025] Such as Figure 1 to Figure 6 , which is a structural schematic diagram of the heat dissipation system of the full-range loudspeaker provided by the first embodiment of the present invention. The heat dissipation system of the full-range loudspeaker includes a basin frame 10, a radiator 20 arranged on one side of the basin bracket 10, a magnet inserted in the radiator 20 and fixedly connected with the basin bracket 10. circuit system 30, a voice coil 40 accommodated in the magnetic circuit system 30, a dust cover 50 fixedly arranged on the voice coil 40, and a centering support arranged in the basin frame 10 60 slices. The heat dissipation system of the full-range speaker also includes some other functional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com