A self-propelled mulberry mower with adjustable stubble cutting height

A technology of self-propelled cutting and paving machines, which is applied in the direction of cutting tools, cutting equipment, agricultural machinery and implements, etc. It can solve the problems of large vibration and inability to cut branches, and achieve high work efficiency, high cutting efficiency and flexible operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

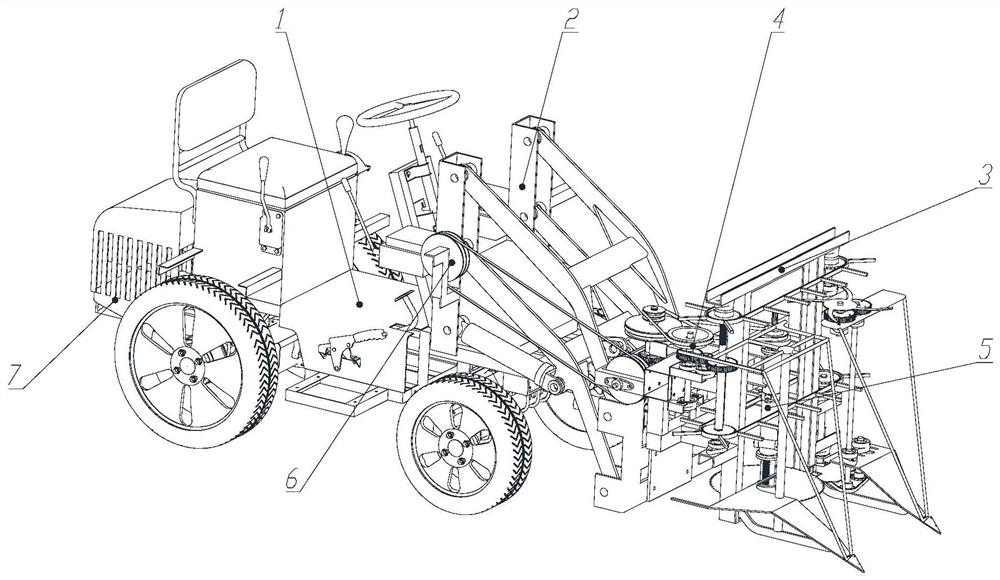

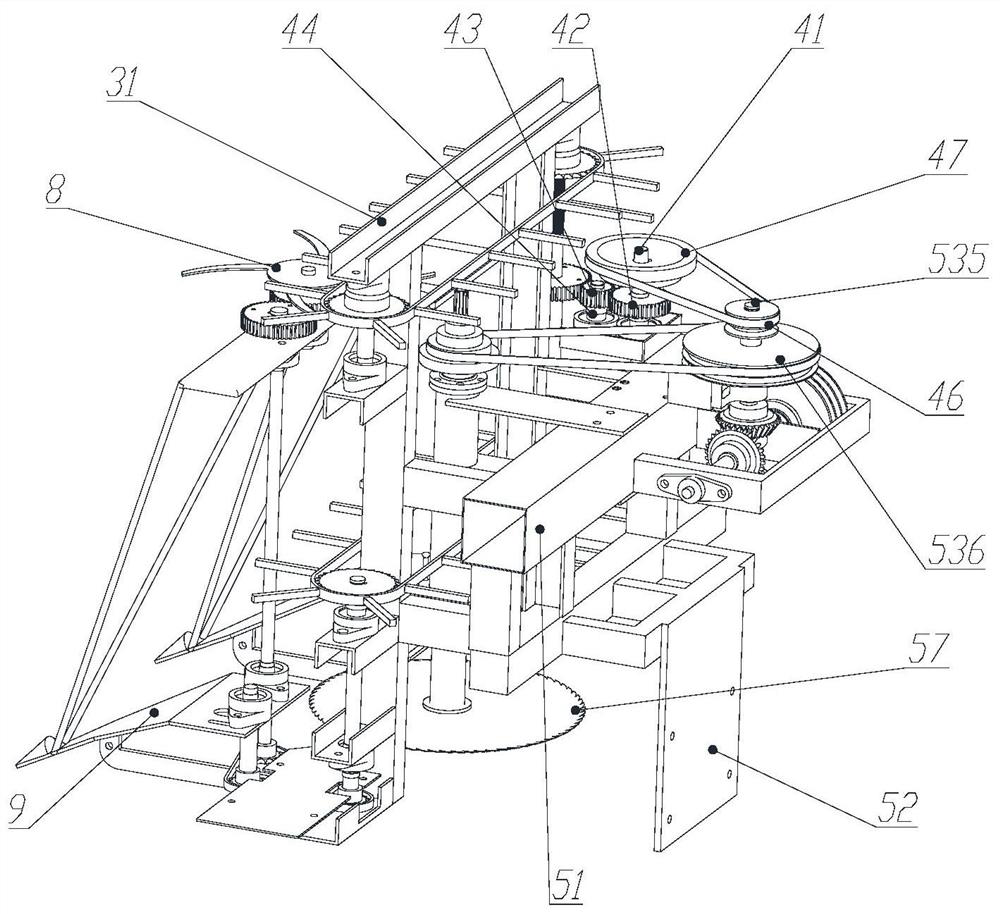

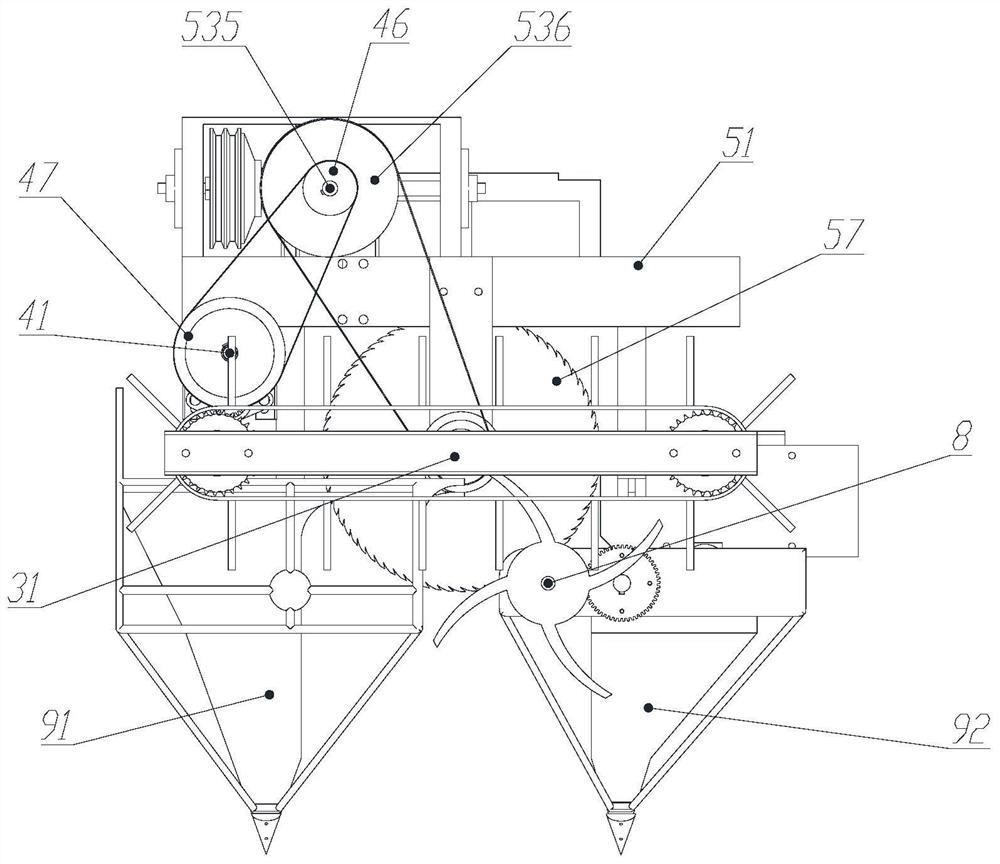

[0061] Please combine Figure 1-Figure 7 , a self-propelled mulberry cutting and paving machine with adjustable stubble cutting height, comprising a tractor 1, a lifting mechanism 2, a knife cutting mechanism 5, a power transmission mechanism 4, a transporting and arranging mechanism 3, a mulberry puller 8 and a fuso device 9. The tractor 1 is provided with a hydraulic oil tank 7 and a hydraulic pump. The lifting mechanism 2 is connected with the front end of the tractor 1 (i.e. one end in the forward direction), the cutter cutting mechanism 5 is connected with one end of the lifting mechanism 2, and the conveying and arranging mechanism 3 is fixedly connected with the frame side of the cutter cutting mechanism 5 and passed through the power transmission mechanism. 4 is connected with the first transmission mechanism of the cutter cutting mechanism 5, and the mulberry puller 8 and the mulberry device 9 are all connected with one side of the conveying branch arrangement 3.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com