Production method of olive nasal spray

A production method, the technology of olive nose, applied in the field of medicine, can solve problems such as poor stability, nasal injury, and single function of nasal spray, and achieve good stability and good antiseptic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

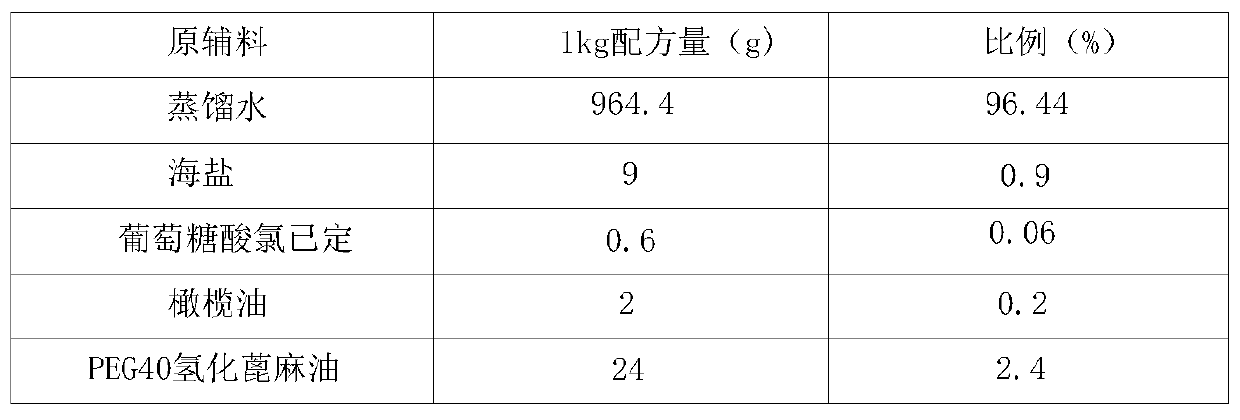

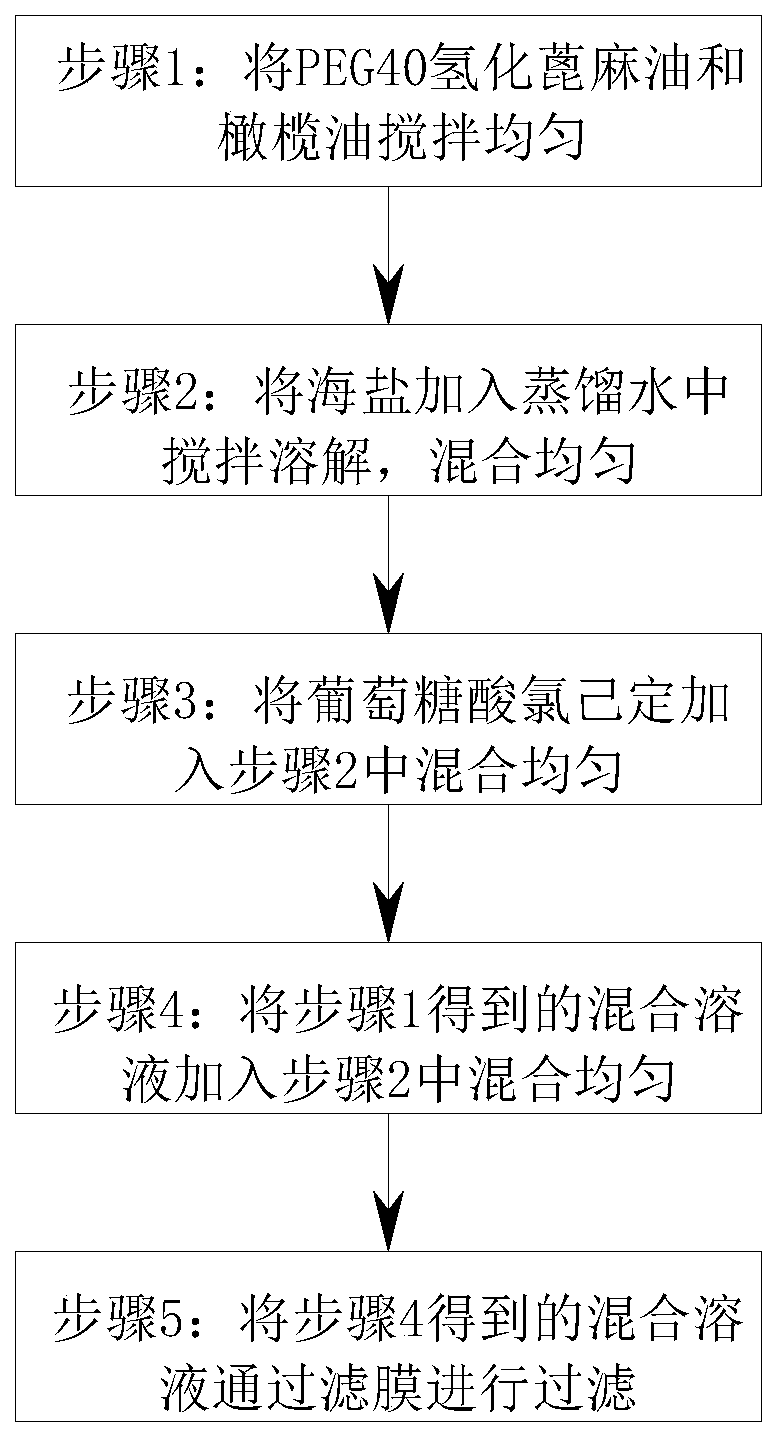

[0025] A production method of olive nasal spray, comprising distilled water, sea salt, chlorhexidine gluconate, olive oil and PEG-40 hydrogenated castor oil, the mass fraction of each component is respectively set to distilled water 96.44%, sea salt 0.9%, gluconic acid Chlorhexidine 0.06%, olive oil 0.2% and PEG-40 hydrogenated castor oil 2.4%, the mass ratio of olive oil and PEG-40 hydrogenated castor oil is set to 1:12, distilled water is set to redistilled water, and its preparation process is set to : After the hard water is heated, use cold water for heat exchange to cool the water vapor, collect the obtained primary distilled water, and remove the non-volatile components remaining in the container, and collect the 60% middle part of the volatile primary distilled water. In the secondary distiller, heat and distill again, use cold water to pass through the heat exchange to cool the water vapor, collect the double distilled water, set the pH value of the olive nasal spray s...

Embodiment 2

[0033] A production method of olive nasal spray, comprising distilled water, sea salt, chlorhexidine gluconate, olive oil and PEG-40 hydrogenated castor oil, the mass fraction of each component is respectively set to distilled water 96.14%, sea salt 0.9%, gluconic acid Chlorhexidine 0.06%, olive oil 0.3% and PEG-40 hydrogenated castor oil 2.6%, the mass ratio of olive oil and PEG-40 hydrogenated castor oil is set to 1:12, distilled water is set to redistilled water, and its preparation process is set to : After the hard water is heated, exchange heat with cold water to cool the water vapor, collect the obtained primary distilled water, remove the non-volatile components remaining in the container, and collect the middle part of 60% of the distillate from the volatile primary distilled water, put it into In the secondary distiller, heat and distill again, use cold water to pass through the heat exchange to cool the water vapor, collect the double distilled water, set the pH valu...

Embodiment 3

[0042]A production method of olive nasal spray, comprising distilled water, sea salt, chlorhexidine gluconate, fragrance, olive oil and PEG-40 hydrogenated castor oil, the mass fractions of each component are respectively set as distilled water 96.34%, sea salt 0.9% , chlorhexidine gluconate 0.06%, fragrance 0.1%, olive oil 0.2% and PEG-40 hydrogenated castor oil 2.4%, the mass ratio of olive oil to PEG-40 hydrogenated castor oil is set to 1:12, distilled water is set to weight Distilled water, the preparation process is set as follows: After the hard water is heated, use cold water to pass heat exchange to cool the water vapor, collect the obtained primary distilled water, remove the non-volatile components remaining in the container, and collect 60% of the volatile primary distilled water % middle part, put it into the secondary distiller, heat and distill again, pass heat exchange with cold water to cool the water vapor, collect the double distilled water, set the pH value o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com