Full-automatic dye batching system

A batching system and fully automatic technology, applied in the field of dyeing, can solve problems such as unevenness, affecting product quality, uneven mixing dyeing, etc., to achieve the effect of maintaining concentration, improving dyeing quality, and increasing the speed of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the drawings.

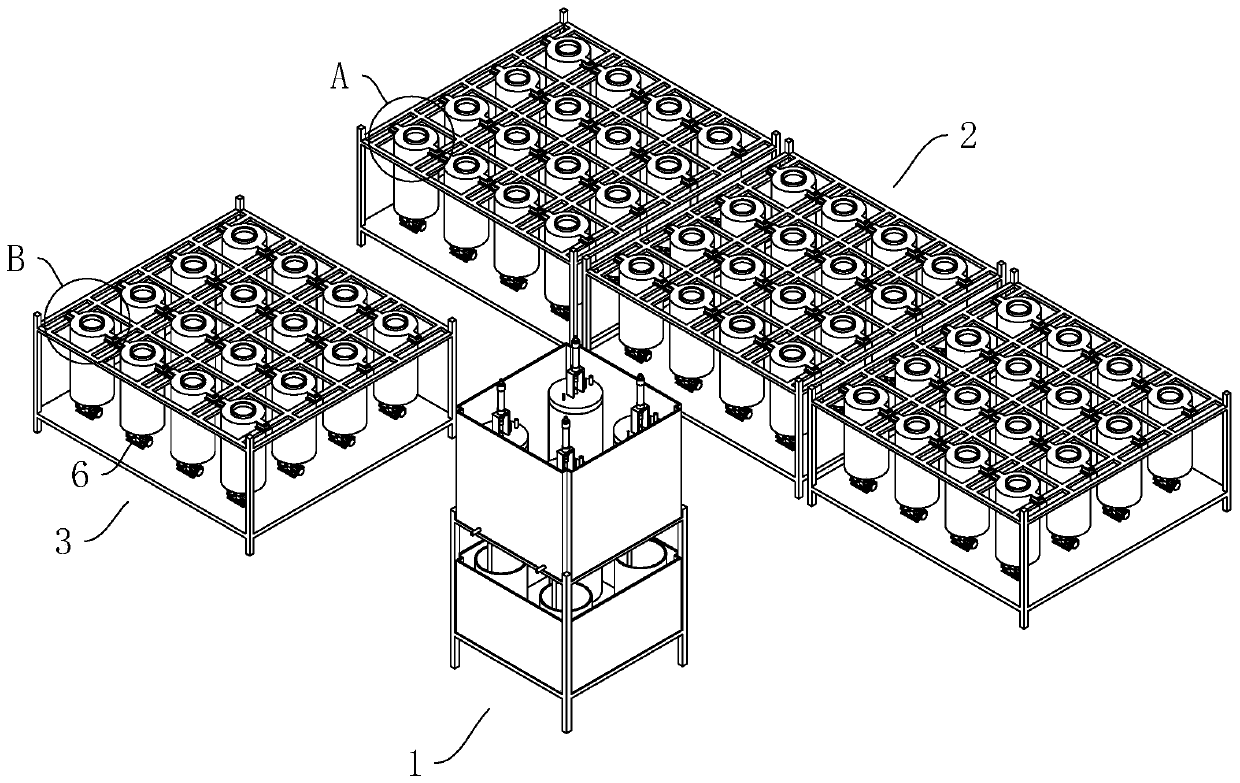

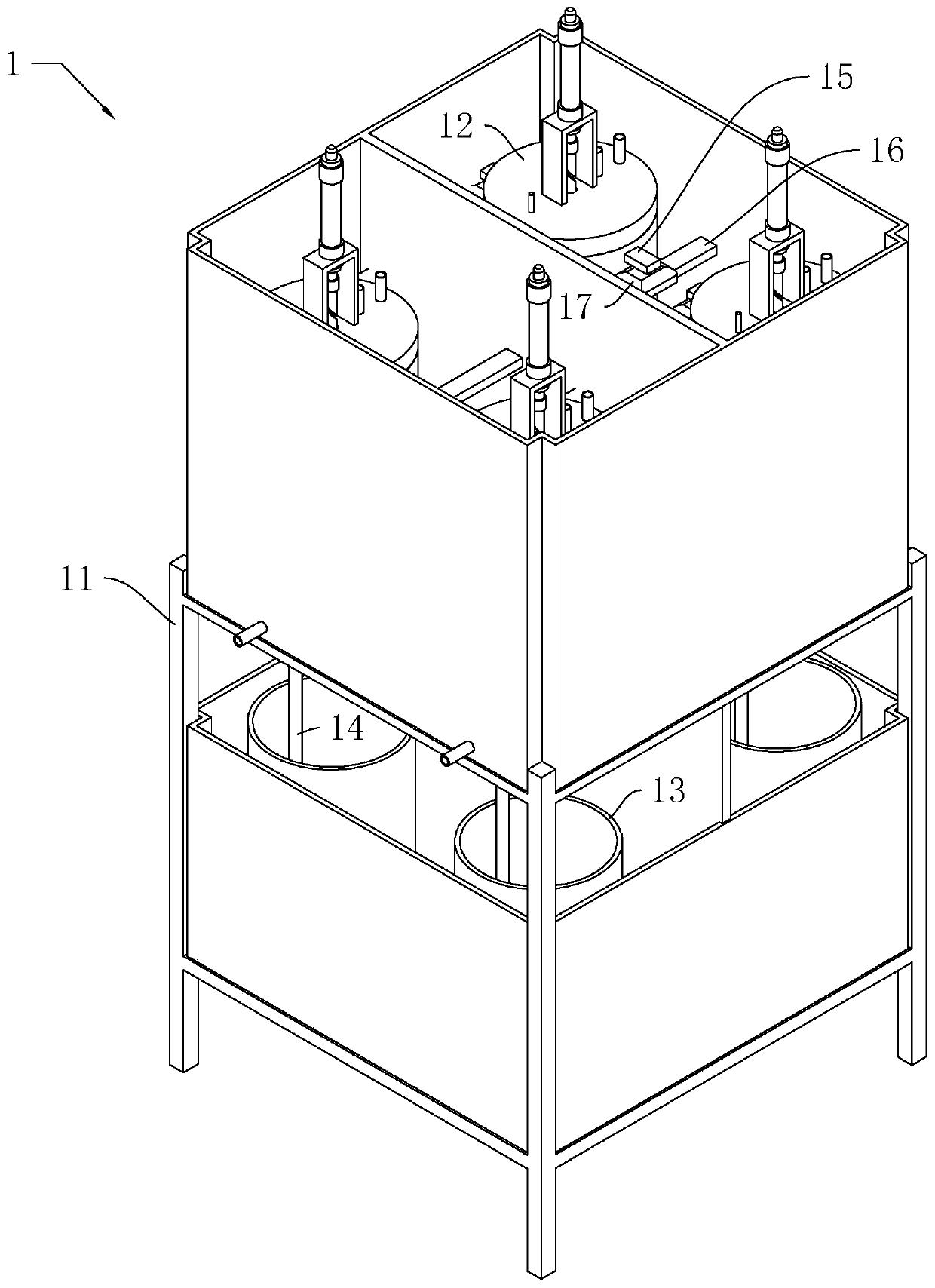

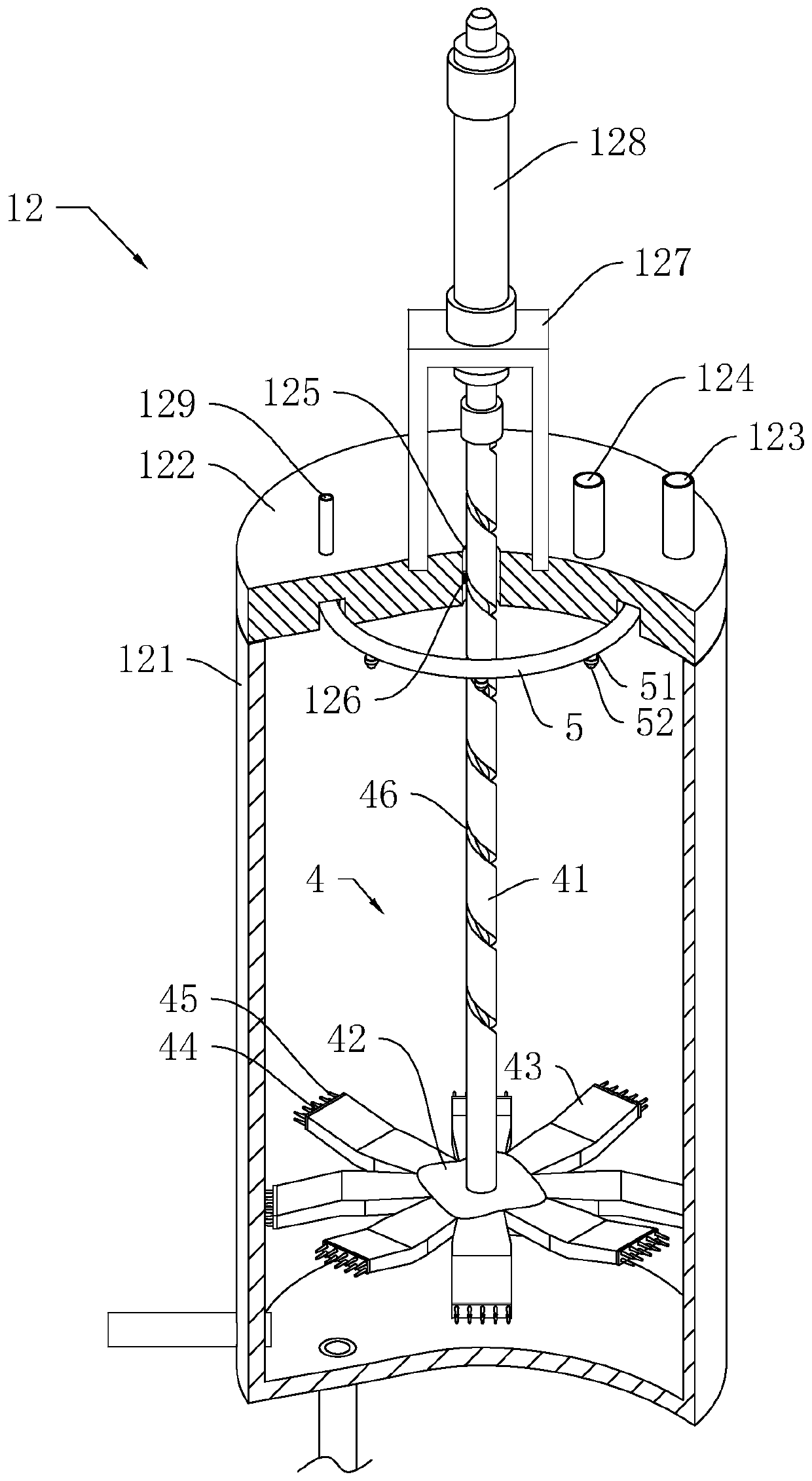

[0038] Such as figure 1 As shown, an automatic dye batching system includes a batching mechanism 1, multiple groups of storage mechanisms 2 and a mixing mechanism 3 arranged in sequence.

[0039] When using the above-mentioned batching system, the batching mechanism 1 is used to prepare monochromatic dye liquors of different colors and different concentrations, and then the monochromatic dye liquors of different colors and different concentrations are discharged one by one into multiple groups of storage mechanisms 2. At this time, each group The color of the dye solution on the storage mechanism 2 is uniform, but the concentration is not the same.

[0040] When it is necessary to mix multiple monochromatic dye liquors of different colors and different concentrations into a new color dye liquor, the monochromatic dye liquors of different colors and different concentrations are j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com