Nano titanium dioxide/wood powder composite material and preparation method and application thereof

A technology of nano-titanium dioxide and composite materials, which is applied in the field of nano-titanium dioxide/wood powder composite materials and its preparation, can solve the problems of composite materials such as unsatisfactory light absorption efficiency, restrictions on in-depth research, and reduced light absorption efficiency of photocatalysts. Simple equipment Easy to implement, reduce environmental pollution, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0033] Example 1

[0034] Get the aqueous solution (NaOH: urea: H 2 The mass ratio of O is 7:12:81), after stirring rapidly for 30min, the wood flour is partially dissolved to obtain a suspension with a certain viscosity, and the suspension is slowly added dropwise to 50mL of titanium sulfate solution (1mol / L), and stirred for aging. After melting for 30 min, the mixture was transferred to a hydrothermal reaction kettle, heated at 120°C for 12h, cooled to room temperature naturally, the precipitate was collected, washed several times with deionized water, the pH of the filtrate was adjusted to neutral, and dried in an oven at 70°C Dry weighing to obtain nano-TiO 2 / Wood flour composites. For the prepared nano-TiO 2 / Wood flour composites were characterized as follows:

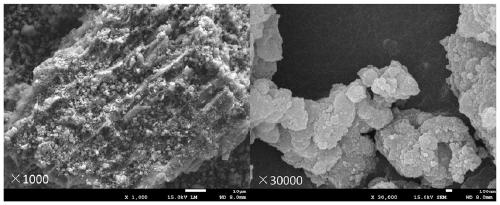

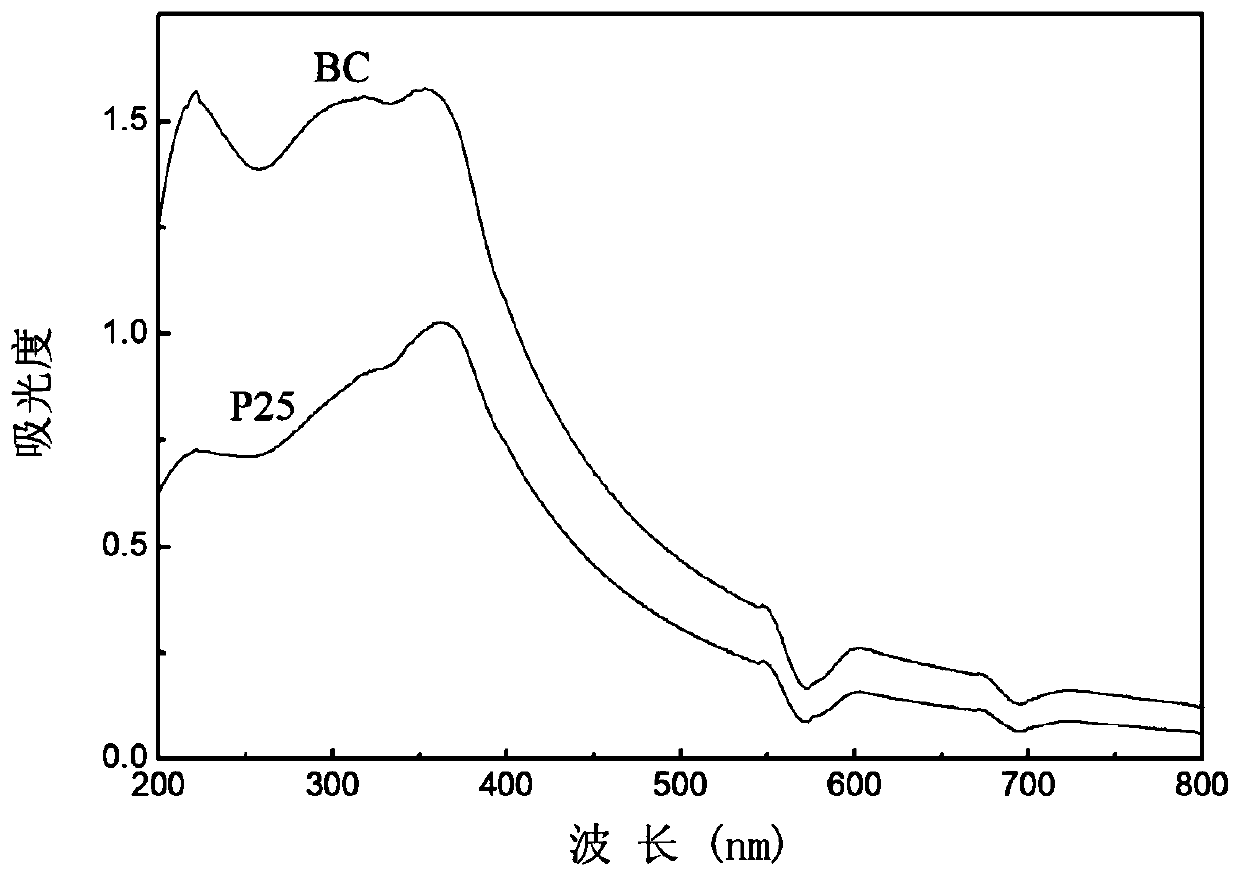

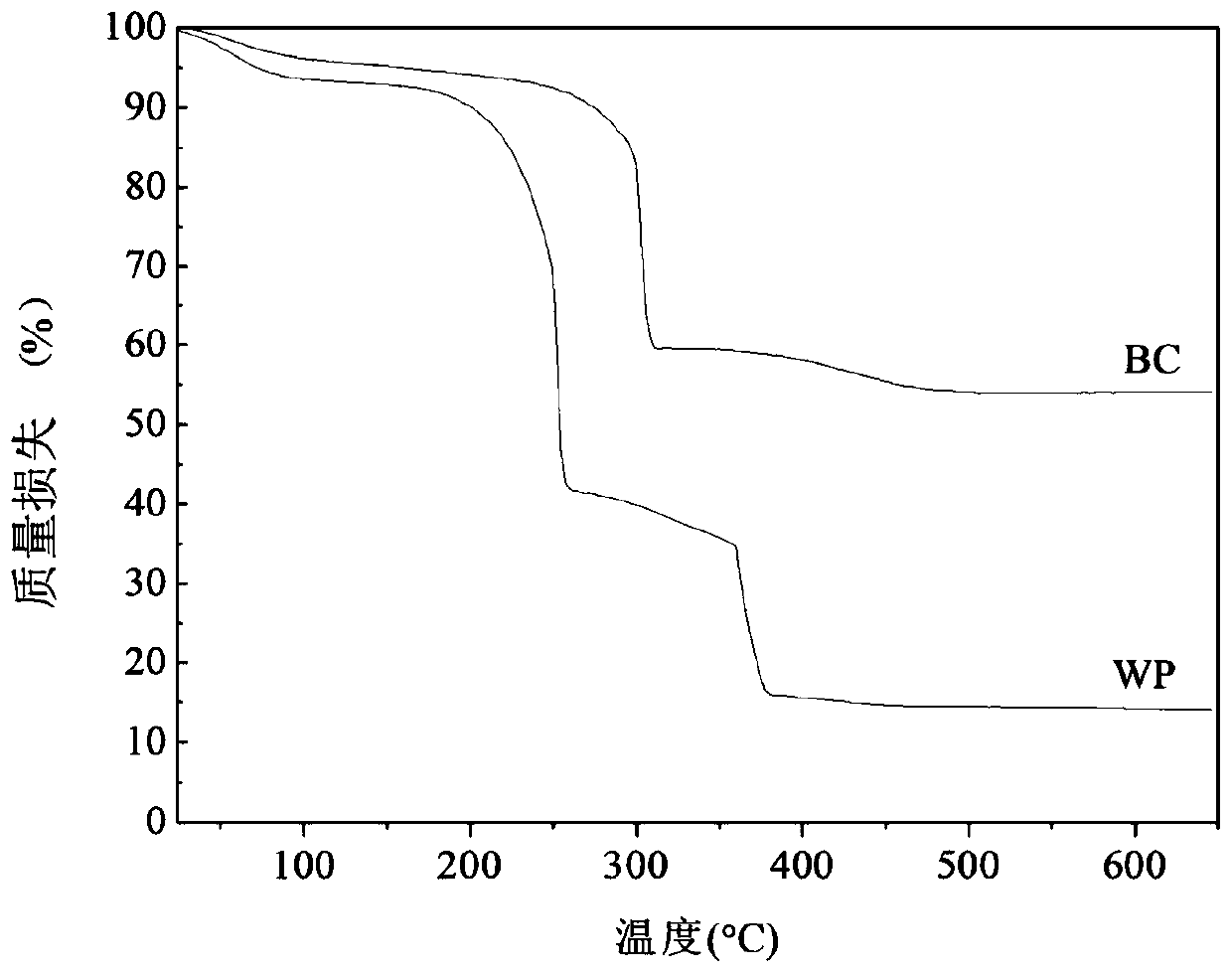

[0035] The prepared nano-TiO 2 / The electron microscope picture of wood powder composite material is as follows figure 1 As shown, it can be seen from the electron microscope that TiO 2 It gathers on t...

Example Embodiment

[0046] Example 2

[0047] Take 50g of NaOH / urea aqueous solution (NaOH: urea: H 2 The mass ratio of O is 7: 12: 81), add 2 g of the wood powder of the sage bark pretreated by ball milling, stir rapidly until dissolved, add the suspension dropwise to 50 mL of titanium sulfate solution (1mol / L), and age with stirring After 30 minutes, the mixture was transferred to a hydrothermal reaction kettle, heated at 120°C for 4h, cooled to room temperature naturally, the precipitate was collected, washed several times with deionized water, the pH of the filtrate was adjusted to neutral, and dried in an oven at 70°C Weigh to get nano TiO 2 / Wood flour composites. from Figure 7 TiO can be seen in the electron microscope image 2 Nanoparticles aggregated into a cauliflower-like dispersion on the surface of wood flour, the prepared nano-TiO 2 / Wood powder composite material is carried out XRD test, from XRD pattern ( Figure 8 ), it can be seen that the diffraction angles 2θ=23.35°, 37...

Example Embodiment

[0048] Example 3

[0049] Take 50g of NaOH / urea aqueous solution (NaOH: urea: H 2 The mass ratio of O is 7: 12: 81), add 2g of Humulus twig ball-ground wood powder, stir rapidly to dissolve, drop the suspension into 50mL titanium sulfate solution (1mol / L), stir and age for 30min, and The mixture was transferred to a hydrothermal reaction kettle, heated at 90°C for 2h, cooled naturally to room temperature, the precipitate was collected, washed several times with deionized water, the pH of the filtrate was adjusted to neutral, dried in an oven at 70°C, and calcined at 300°C 2h. Weigh to get nano TiO 2 / Wood flour composites. from Figure 9 Calcined TiO can be seen in the electron microscope image 2 Being sintered together, only a few particles float on the surface. For the prepared nano-TiO 2 / Wood powder composite material is carried out XRD test, from XRD pattern ( Figure 8 ), it can be seen that the diffraction angles 2θ=23.35°, 37.01°, 48.0° and 54.30°, correspondi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap