A kind of organic rice production line

A production line and organic rice technology, applied in the fields of grain finishing, grain degerming, agriculture, etc., can solve the problem of not being able to use unhulled rice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

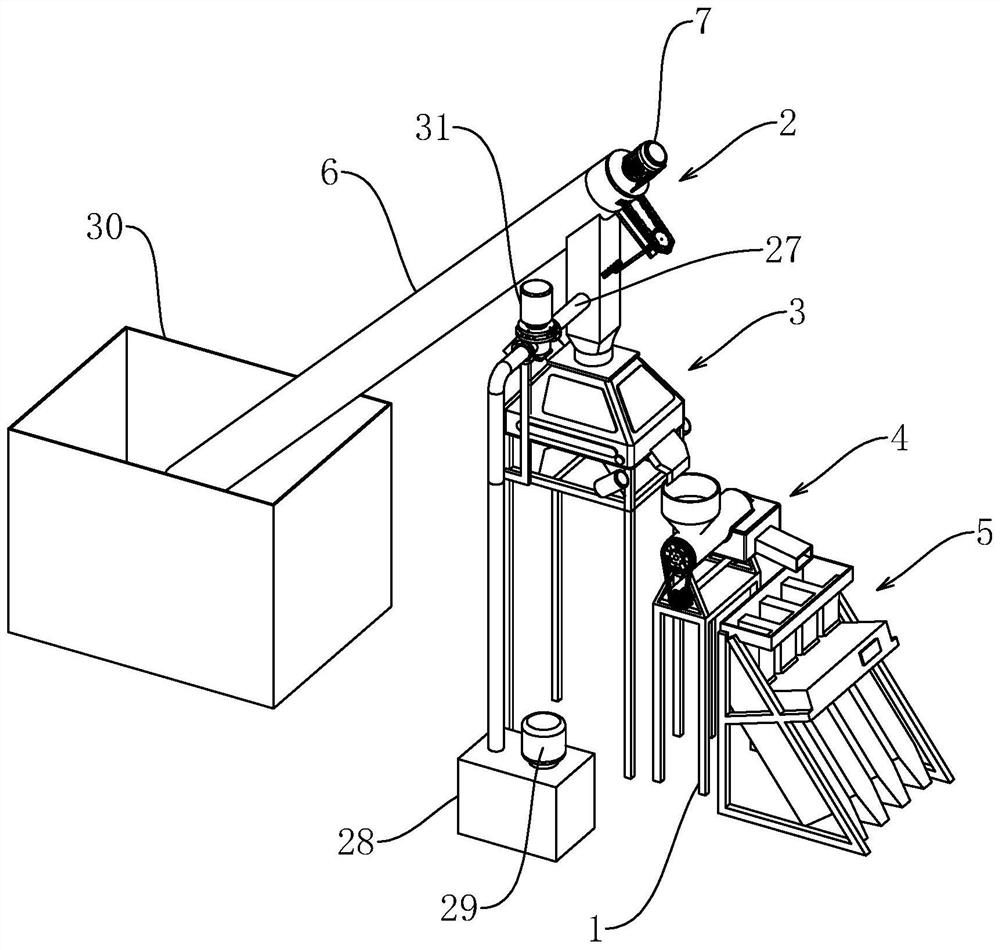

[0032] Such as figure 1 Shown, a kind of organic rice production assembly line, comprises frame 1 and is positioned at frame 1 and is used for lifting paddy and completes the hoisting hulling machine 2 of hulling, the destoner 3 that removes stone grain, the milling machine that whitens rice Rice machine 4 and the screening machine 5 of screening rice.

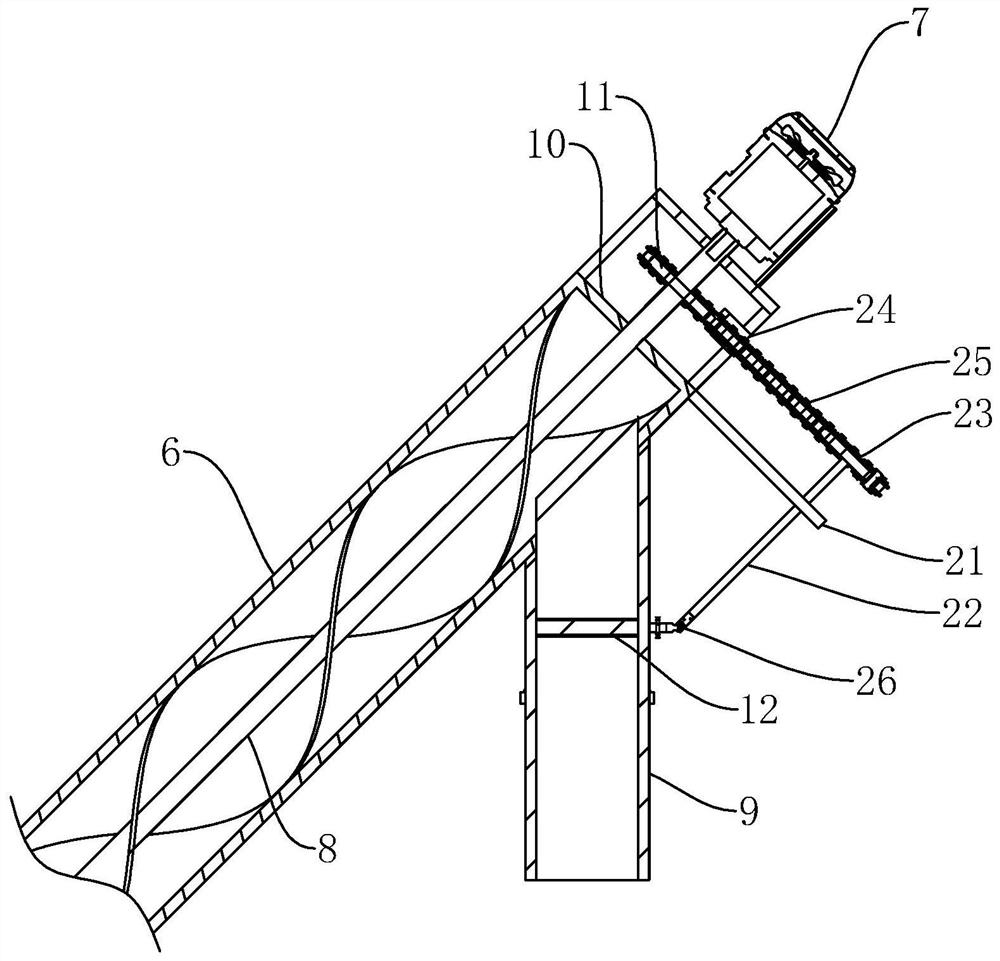

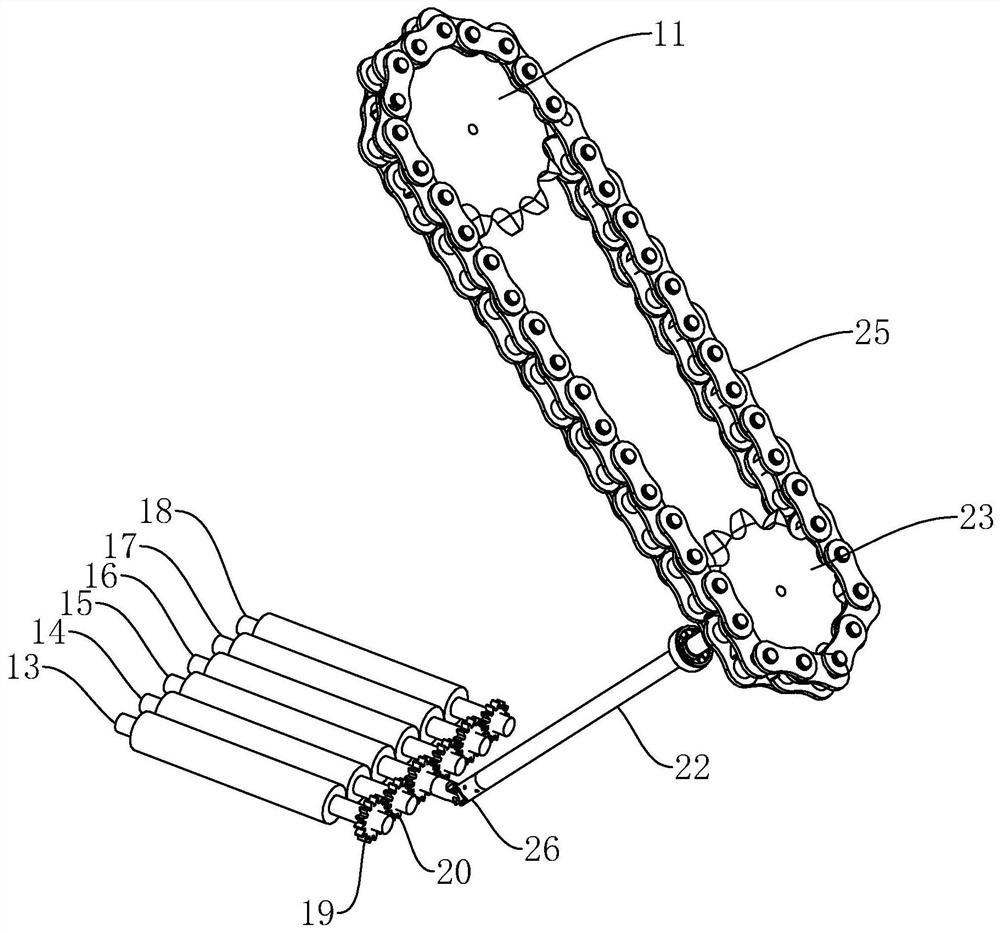

[0033] Such as figure 1 and figure 2 As shown, the lifting sheller 2 includes a feeding pipe 6 arranged obliquely, and the lower end of the feeding pipe 6 is inserted into the feed box 30 . Feed pipe 6 is a round pipe, and the upper end of feed pipe 6 is equipped with feed motor 7, and the output end of feed motor 7 is fixedly connected with conveying screw rod 8, and conveying screw rod 8 is arranged along the length direction of feed pipe 6. The conveying screw 8 is driven by the feeding motor 7 to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com