Cooling liquid control device

A control device and coolant technology, which is applied in the direction of manufacturing tools, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problem that there is no way to meet the coolant injection, and achieve the effect of increasing the discharge speed and improving the machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

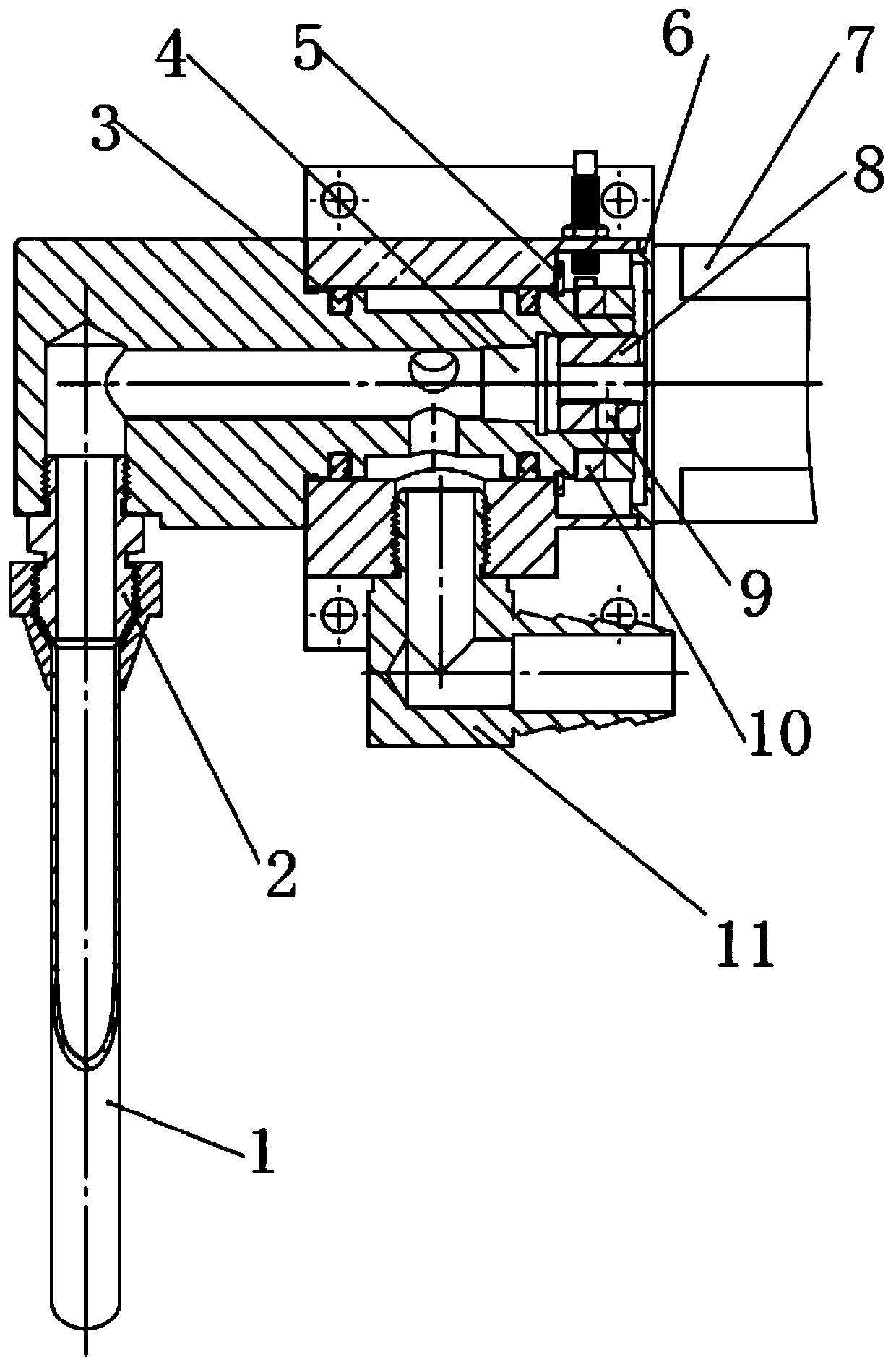

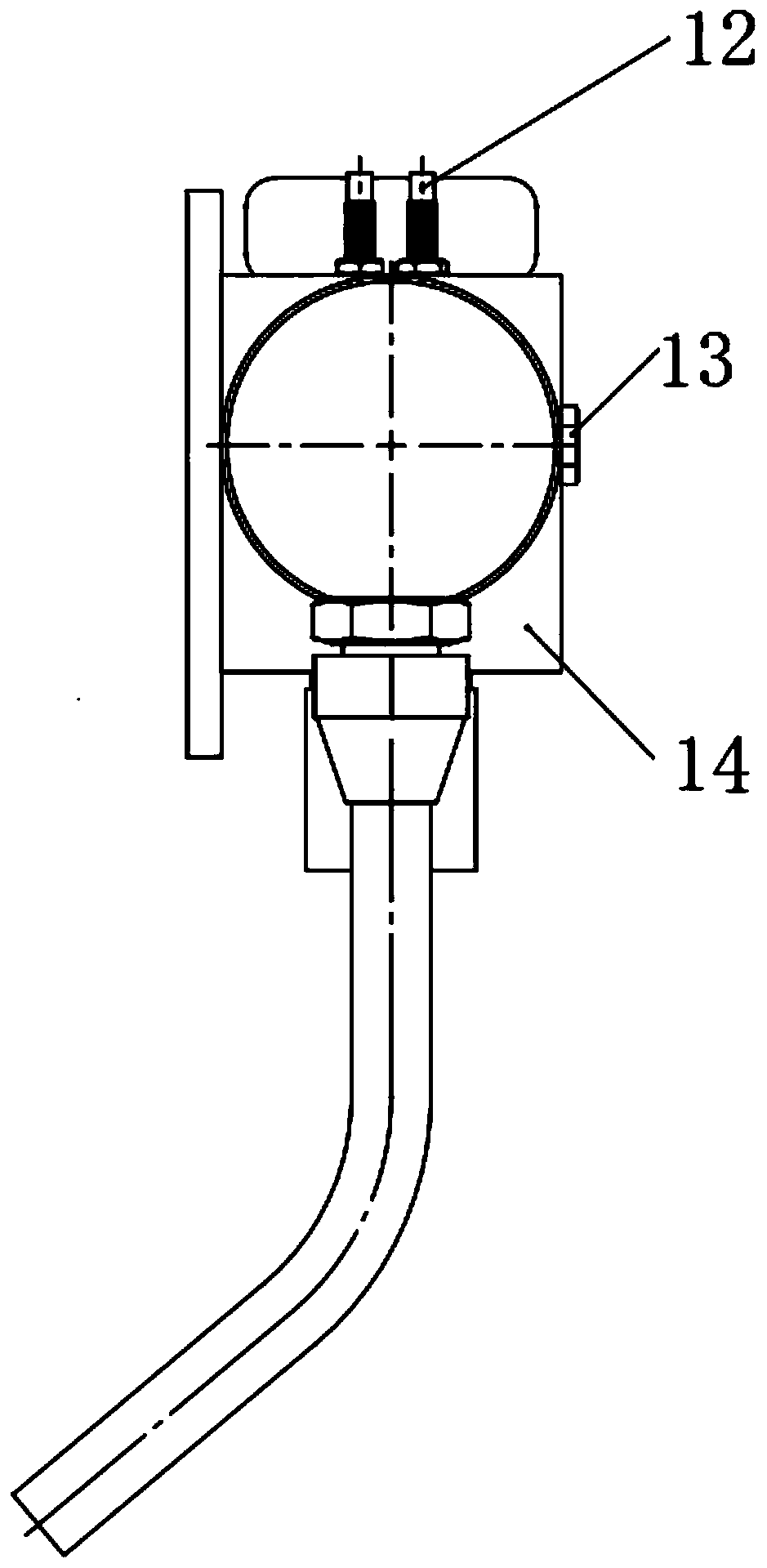

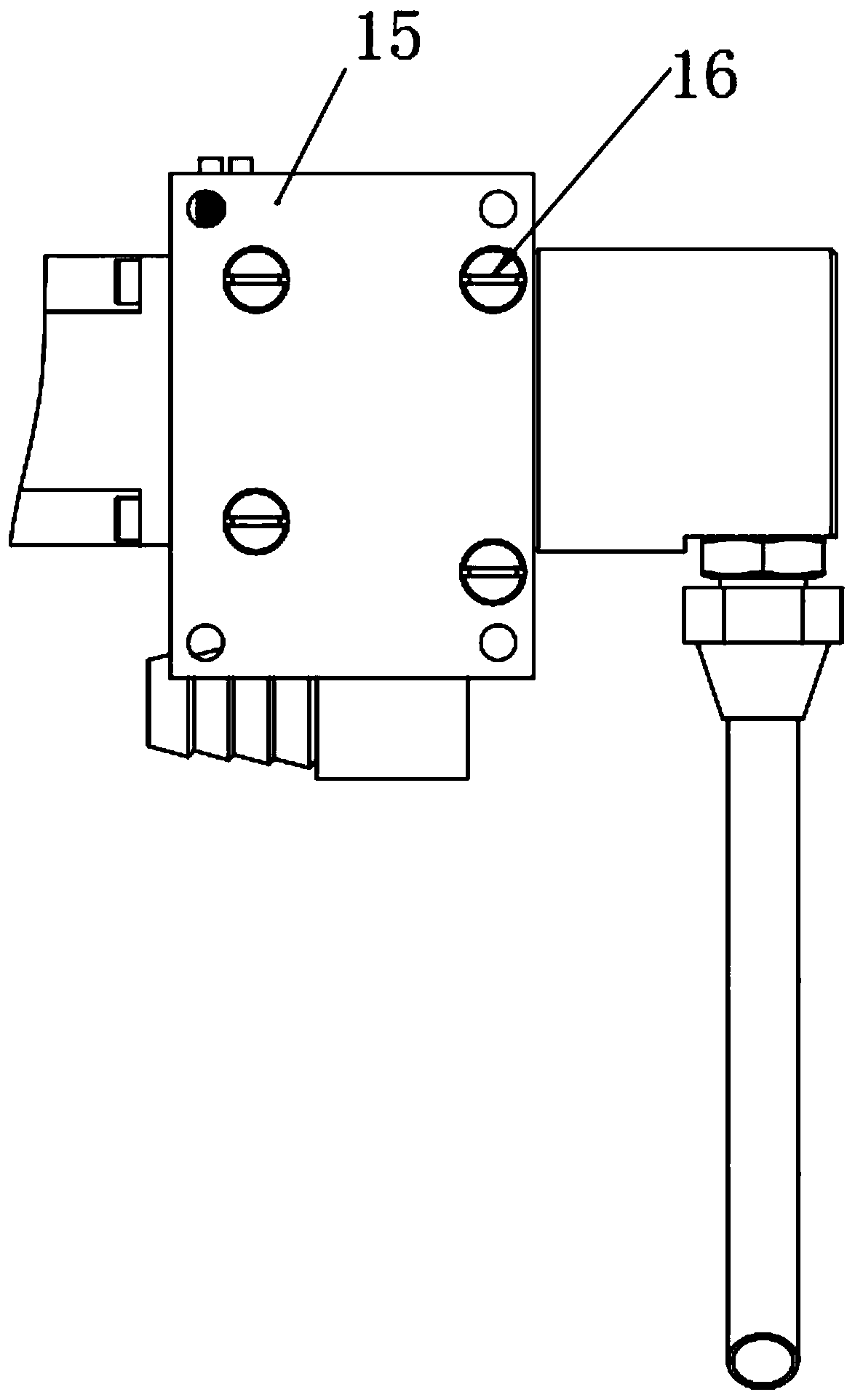

[0025] see Figures 1 to 5 , In the embodiment of the present invention, a cooling liquid control device includes a valve body 14, a valve core 17 and a control motor 7, the lower side of the valve core 17 is connected with a pipe 1 through a straight pipe joint 2, and the valve body 14 A two-way piston seal 3 is arranged between the valve core 17 and the valve body 14. A positioning plate 6 is arranged at the right end of the valve body 14. The valve body 14 is connected to the control motor 7 through the positioning plate 6, and a bump block is arranged between the positioning plate 6 and the valve body 14. 10. A proximity switch 12 is provided on the outside of the valve body 14, a plug 4 is provided in the valve core 17, and a rubber hose square pipe joint 11 is also provided on the lower side of the valve core 17. A shaft retaining ring 5 is provided, and a transition sleeve 8 is provided at the inner right end of the valve core 17 .

[0026] The straight pipe joint 2 is...

Embodiment 2

[0029] On the basis of the first embodiment, the bumper 10 is installed by a set screw with a conical end, and the transition sleeve 8 is connected with the valve core 17 by a set screw 9 with a flat end. It is convenient to install and remove the bumper 10 and the transition sleeve 8 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap