A sleeve grouting joint for prefabricated buildings and its application method

A technology for sleeve grouting and construction, which is used in construction, building components, building reinforcements, etc., can solve the problems of affecting the strength of the sleeve grouting joint, the grouting material is not easy to flow out, and the fluidity of the sleeve is poor, so as to achieve a balance of connection strength. , the effect of increasing strength and reducing the possibility of porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

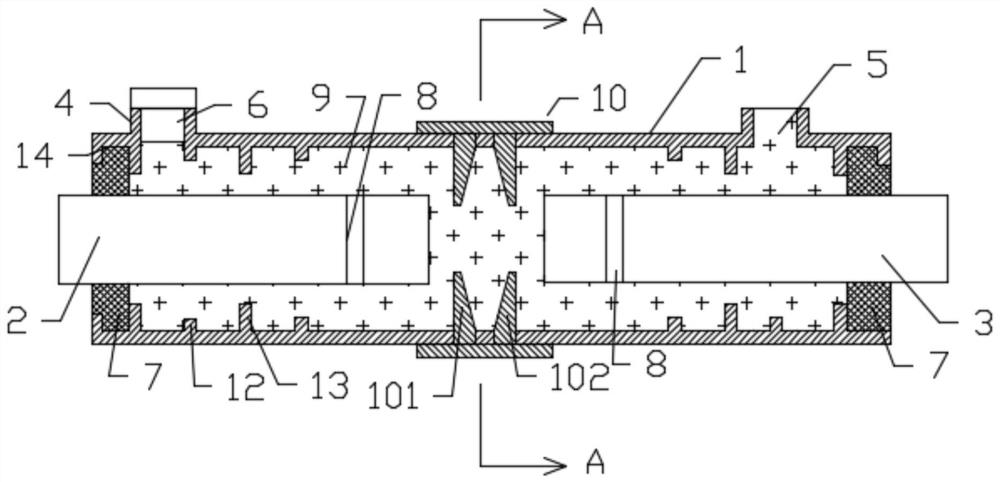

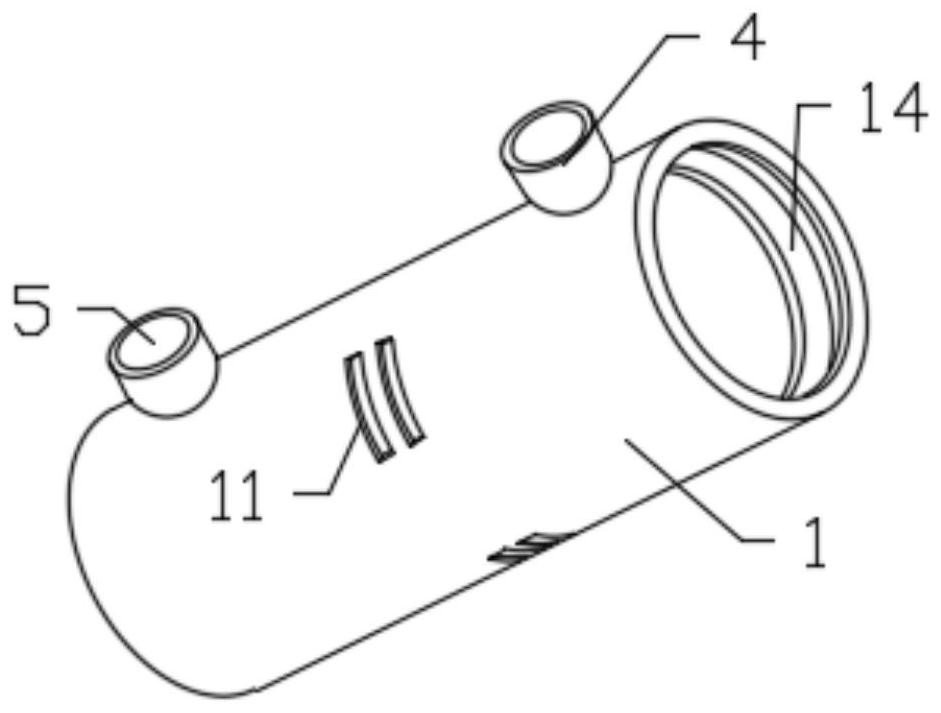

[0026] Hereinafter, the preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0027] figure 1 Is a schematic diagram of the structure of the present invention, figure 2 Is the structure diagram of the sleeve, image 3 It is a schematic diagram of the structure of the connecting rib limiting device. Figure 4 The structure diagram of the main shear key group, Figure 5 Is a schematic diagram of the structure of the secondary shear key group, Image 6 for figure 1 Schematic diagram of the structure along A-A. The present invention is a sleeve grouting joint for fabricated construction, which includes a sleeve 1, a first connecting rib 2 and a second connecting rib 3. The sleeve 1 in this embodiment has a commonly used cylindrical structure, which is a thin-walled cylindrical shape with open ends , It can be round or square. The sleeve 1 is provided with a grouting hole 4 and a grout outlet hole 5. Both the grout ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com