Differential sampling temperature control method of heating system

A technology of sampling temperature and heating system, which is applied in the direction of temperature control using electric mode, which can solve the problems of increasing adjustment period, unable to respond in time, output oscillation, etc., to achieve the effect of enhancing differential effect and suppressing actuator oscillation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with specific embodiment, further illustrate the present invention.

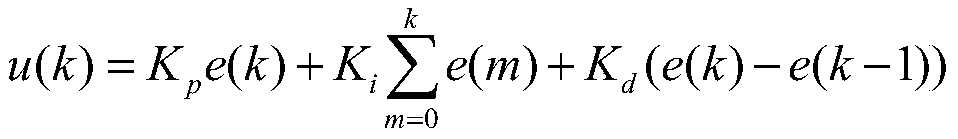

[0027] In the present invention, the sampling period of the error change rate of the heating system is set as several times of the error sampling period. Modify the traditional PID control algorithm to the following result:

[0028]

[0029] The characters in the above formula are defined as follows:

[0030]

[0031] In the above formula, the temperature change difference becomes the difference between the temperature obtained by this sampling and the temperature of the previous n times, and k and n are positive integers.

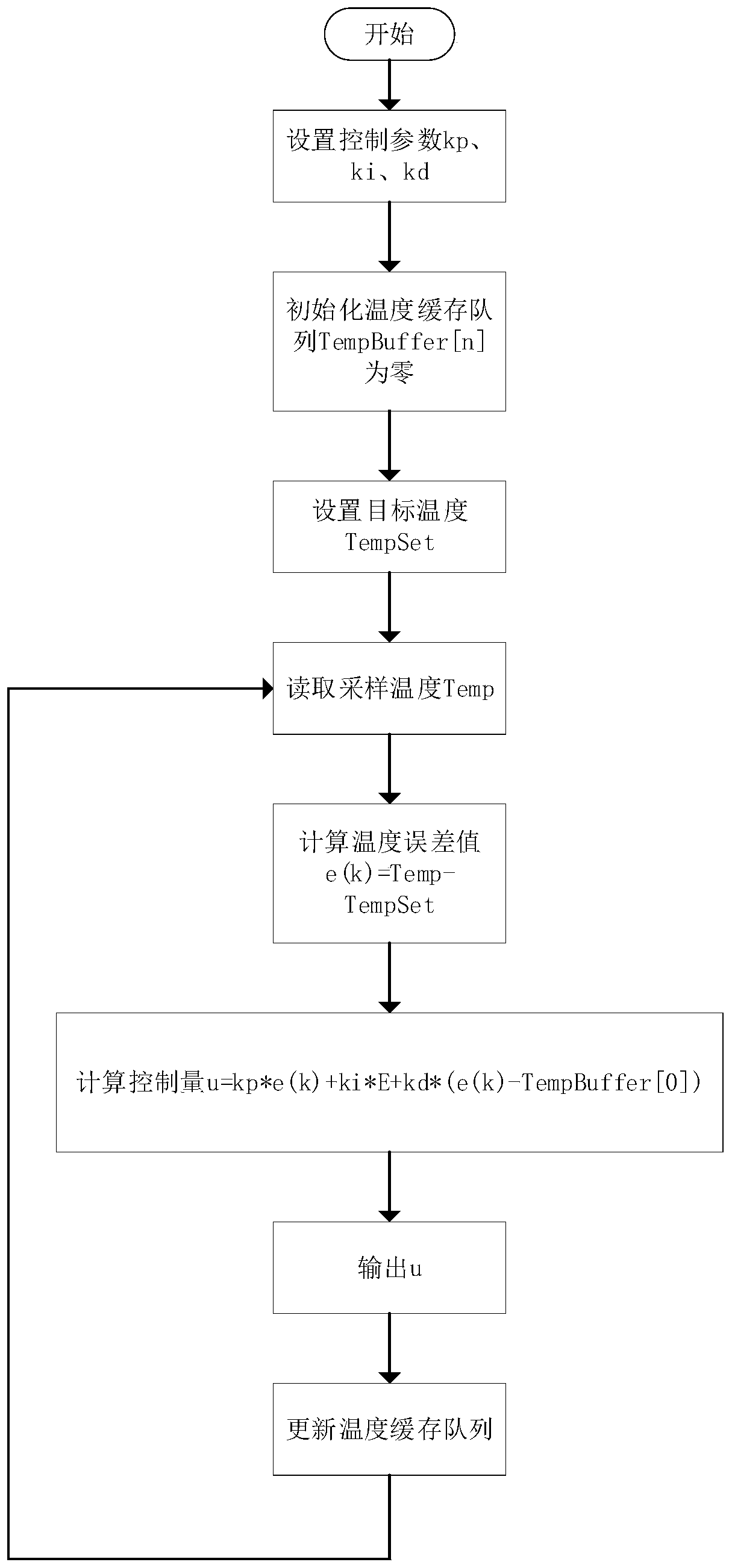

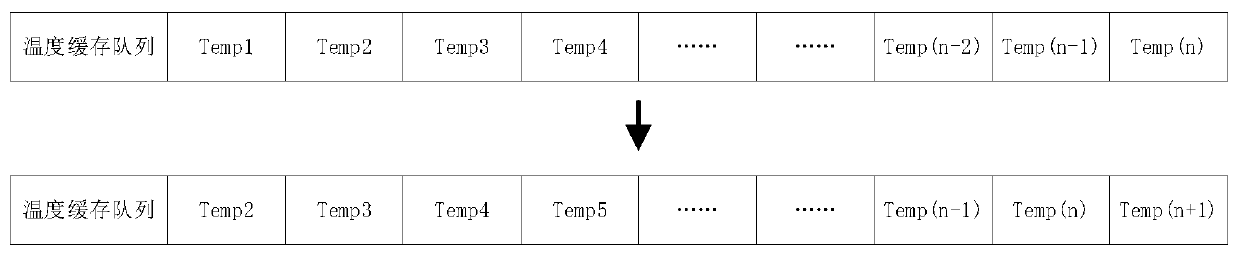

[0032] When the algorithm is implemented, by creating a temperature cache queue, recording the sampling temperature of nearly n times, maintaining a high-speed sampling frequency by exchanging space for time, and obtaining a significant temperature difference to make the differential function effective.

[0033] figure 1 The flow chart of the differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com