Linear continuous static force loading control method

A technology of static loading and control method, applied in the field of control algorithm, can solve the problems of load value shock, unable to continue static loading, unable to accurately linear static loading, etc., to achieve continuous static loading and restrain static value shock Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

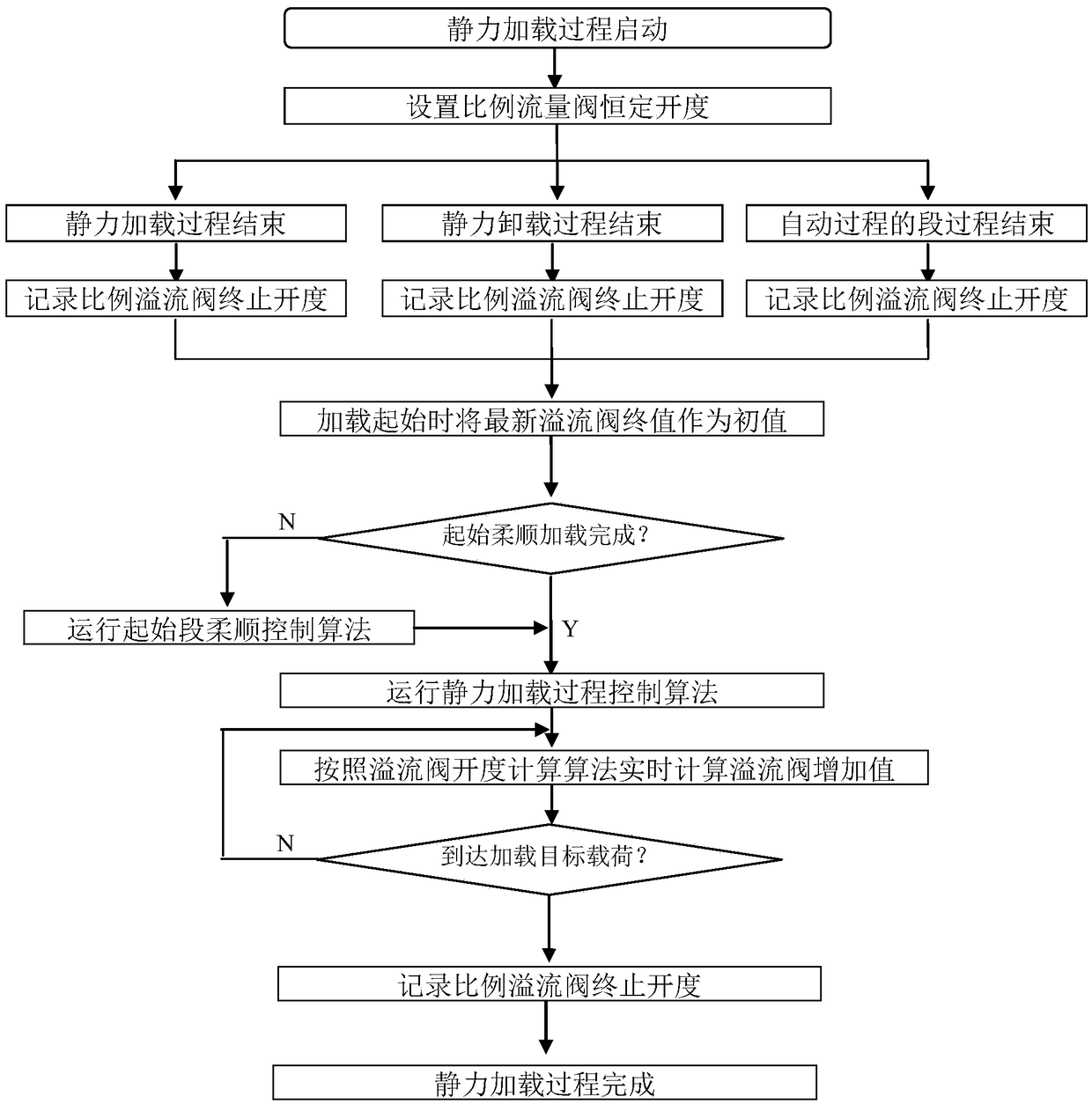

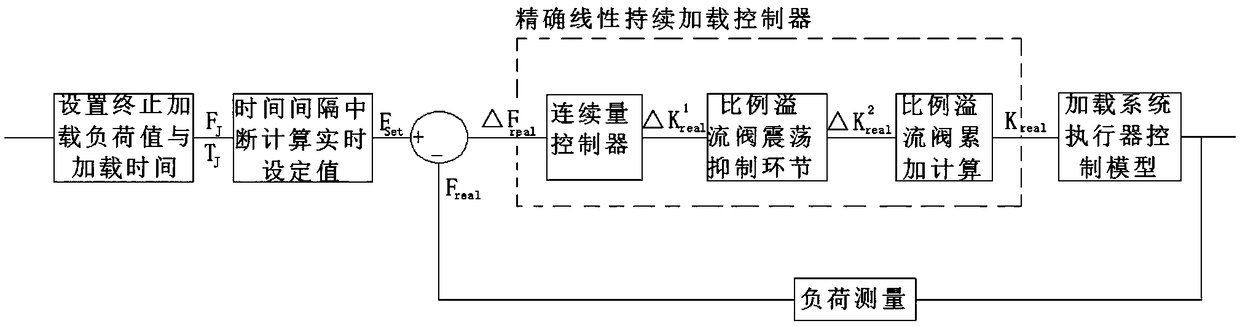

[0040] Such as Figures 1 to 3 As shown, a linear continuous static loading control method for a nonlinear non-integral link hydraulic static loading system, including an accurate linear continuous static loading control method, a method for improving the linearity of the static loading process, and a method for realizing the static loading process method of continuous loading.

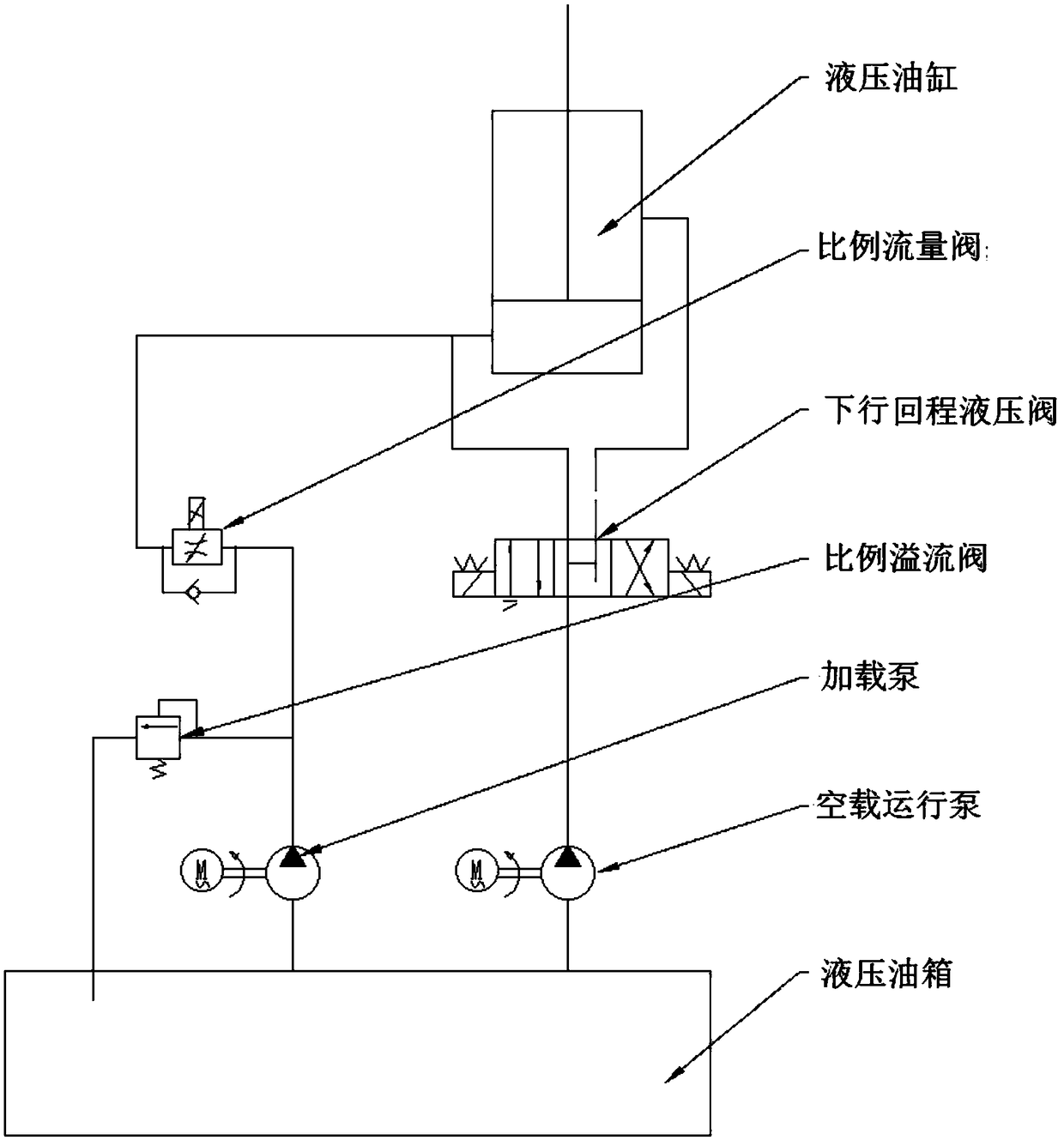

[0041] Among them, the accurate linear continuous static loading control method is based on using the hydraulic pump as the hydraulic power, the hydraulic cylinder as the hydraulic energy output element, the proportional relief valve as the loading force control actuator, and the proportional flow valve as the loading process displacement control element. Hydraulic pressure loading system.

[0042] image 3The key components of the hydraulic pressure loading system and their specific links are specifically shown in , specifically: the hydraulic oil tank is connected with the no-load running pump and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com