Metal-graphite medium-temperature energy storage battery and preparation method thereof

A technology of energy storage batteries and metal graphite, which is applied in the direction of secondary batteries, circuits, electrical components, etc., and can solve problems such as safety accidents, high energy storage costs, and high prices of ion exchange membrane energy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

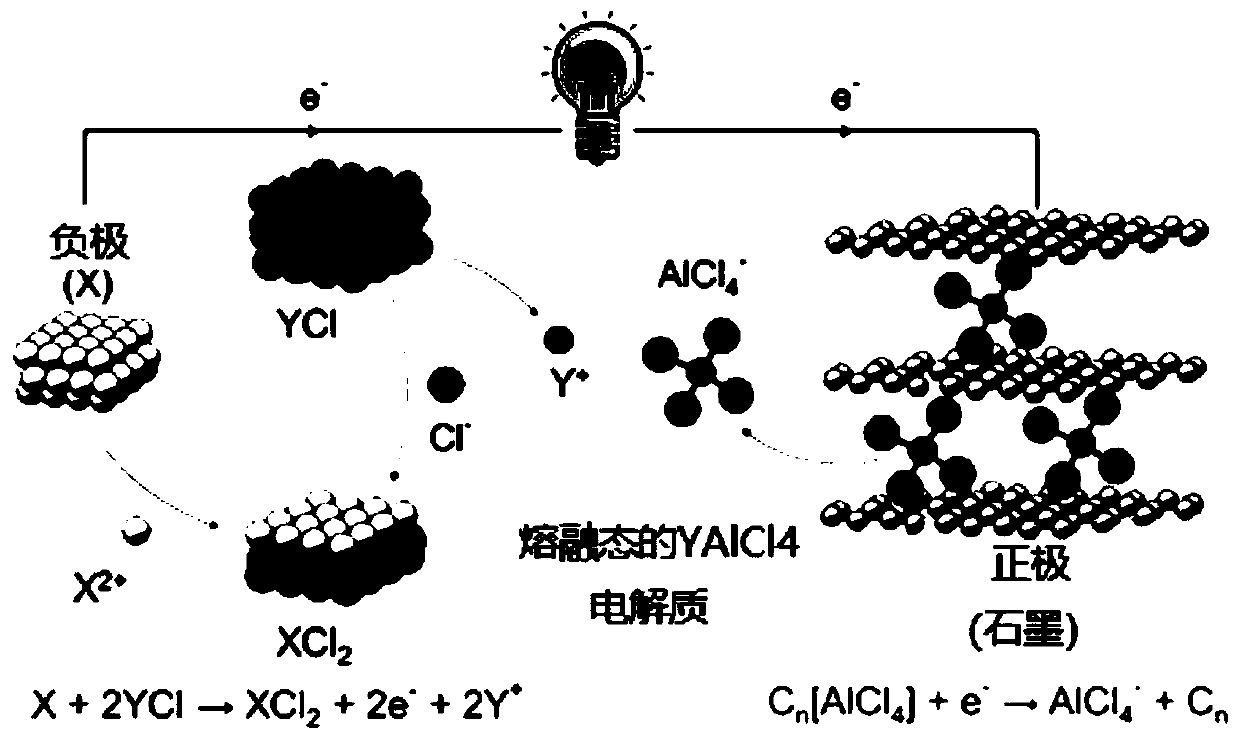

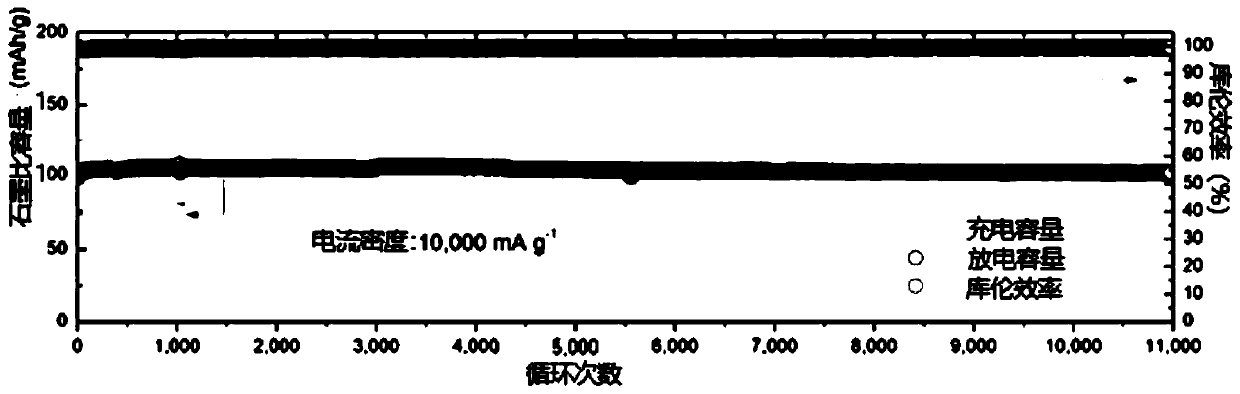

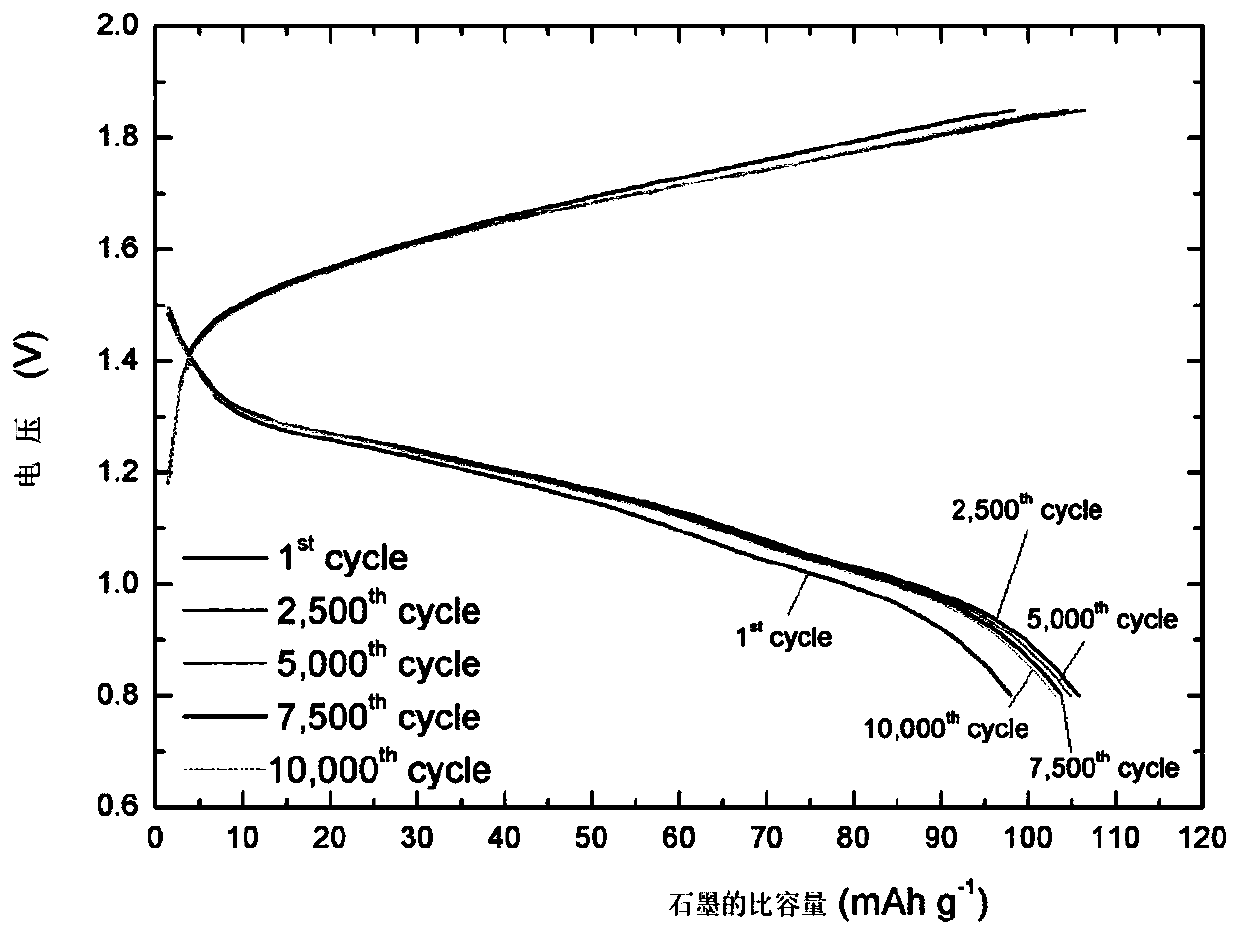

[0063] The negative electrode metal is Fe, and the electrolyte is NaAlCl saturated with NaCl 4 Molten salt electrolyte, the positive electrode is carbon cloth or carbon felt, namely Fe|FeCl 2 |NaAlCl 4 (Saturated NaCl)|Graphite battery as an example. After testing, the battery has a coulombic efficiency of 99.4% for more than 11,000 cycles, and the capacity after the final cycle is only attenuated by 3% compared with the initial capacity. The current density and specific capacity in the figure All calculated relative to the positive electrode graphite material, they are 104mAh / g and 10000mA / g respectively. Metal iron is used as the negative electrode, the cost is low, and the working voltage of the obtained battery is high. Wherein the negative electrode material is prepared by the above-mentioned method one.

Embodiment 2

[0065] The negative electrode metal is Ni foam, and the electrolyte is NaAlCl saturated with NaCl 4 Molten salt electrolyte, positive carbon cloth, assembled into foam Ni|NiCl 2 |NaAlCl 4 (saturated NaCl) | Graphite battery.

[0066] Among them, the negative electrode material is prepared by the above-mentioned method two, and a layer of NiCl is evenly attached to the surface of the foamed Ni. 2 .The assembled battery was tested and found that the battery can work continuously and stably.

Embodiment 3

[0068] The negative electrode metal is Zn, and the electrolyte is NaAlCl saturated with NaCl 4 Molten salt electrolyte, the positive electrode is three-dimensional graphene, that is, Zn|ZnCl 2 |NaAlCl 4 (saturated NaCl) | graphene battery.

[0069] Among them, the negative electrode material is prepared by the above method three, using X powder and XCl with a molar ratio of 2.6:1 2 The powder and additives are uniformly mixed with Al powder and sintered into flakes. The assembled battery was tested and found that the battery can also work continuously and stably.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com