Cooling and dehumidifying power cabinet based on semiconductor chilling plate

A technology of cooling, dehumidification, and refrigerating sheets, which is applied in the substation/distribution device casing, substation/switching device cooling/ventilation, etc., which can solve the problems of not easy to dissipate heat, electrical components, corrosion of power equipment, large space occupation, etc., to achieve Enhance cooling effect, reduce loss, and occupy less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

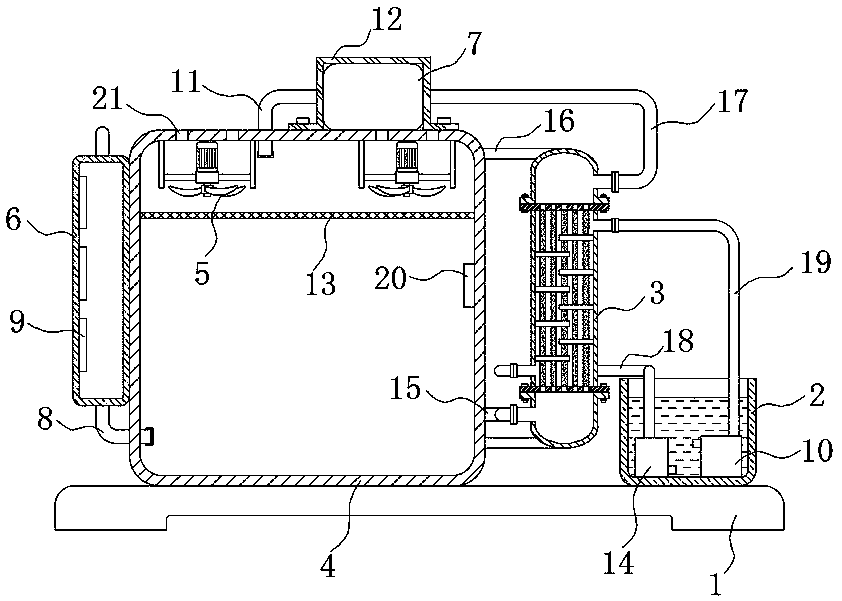

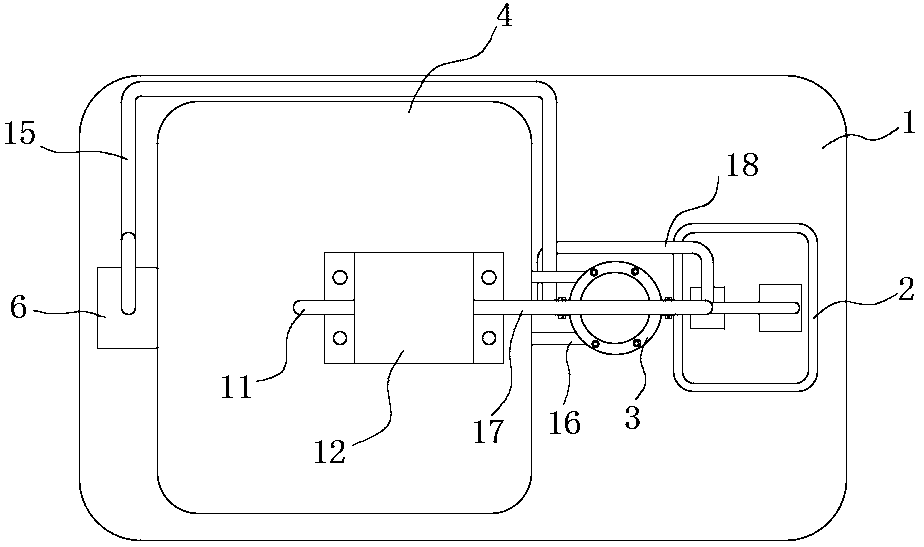

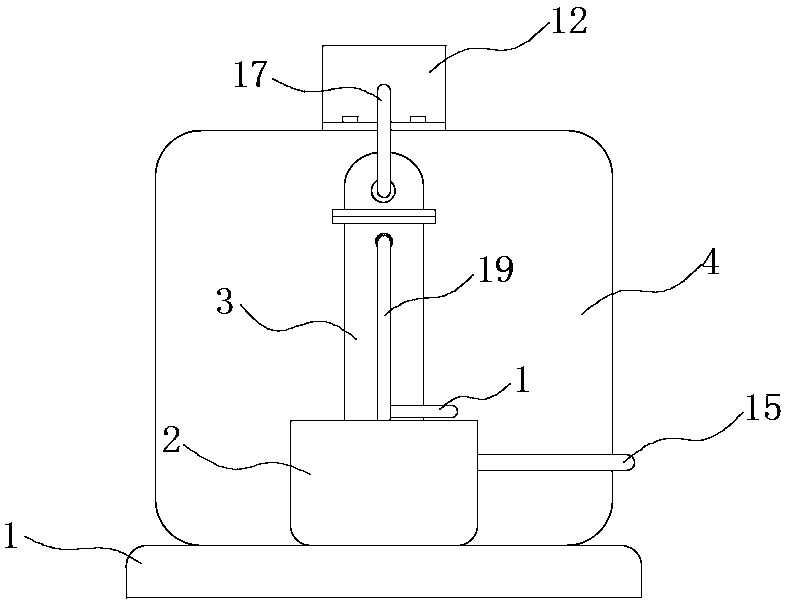

[0038] refer to Figure 1-6 , a cooling and dehumidification power cabinet based on semiconductor refrigeration chips, comprising a base 1, a cabinet body 4 and a water tank 2 are fixedly installed on the upper surface of the base 1.

[0039] A cooling mechanism 3 is fixedly installed on one side wall of the cabinet body 4, and a plurality of connecting rods 16 are symmetrically welded on the outer wall of the cabinet body 4, and the cooling mechanism 3 is installed on the plurality of connecting rods 16, and the cooling mechanism 3 includes cooling A cylinder 301, the two ends of the cooling cylinder 301 are evenly provided with a plurality of air inlets 309, and the cooling cylinder 301 is symmetrically connected with a water inlet pipe 302 and a drain pipe 307, and the water inlet pipe 302 is connected with the cooling water inlet pipe 19, and the drain pipe 307 is connected with the cooling water inlet pipe 19. The cooling outlet pipe 18 communicates.

[0040] A plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com