Volumetric pump

A volumetric pump and volumetric technology, applied in the field of volumetric pumps, can solve problems such as discontinuous flow rate, and achieve the effects of wide range of speed variation, less noise, and low thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Reference attached Figure 5 , according to the invention, the volumetric pump denoted by reference numeral 5 comprises an inlet part 53 and an outlet part 54 in the most basic embodiment.

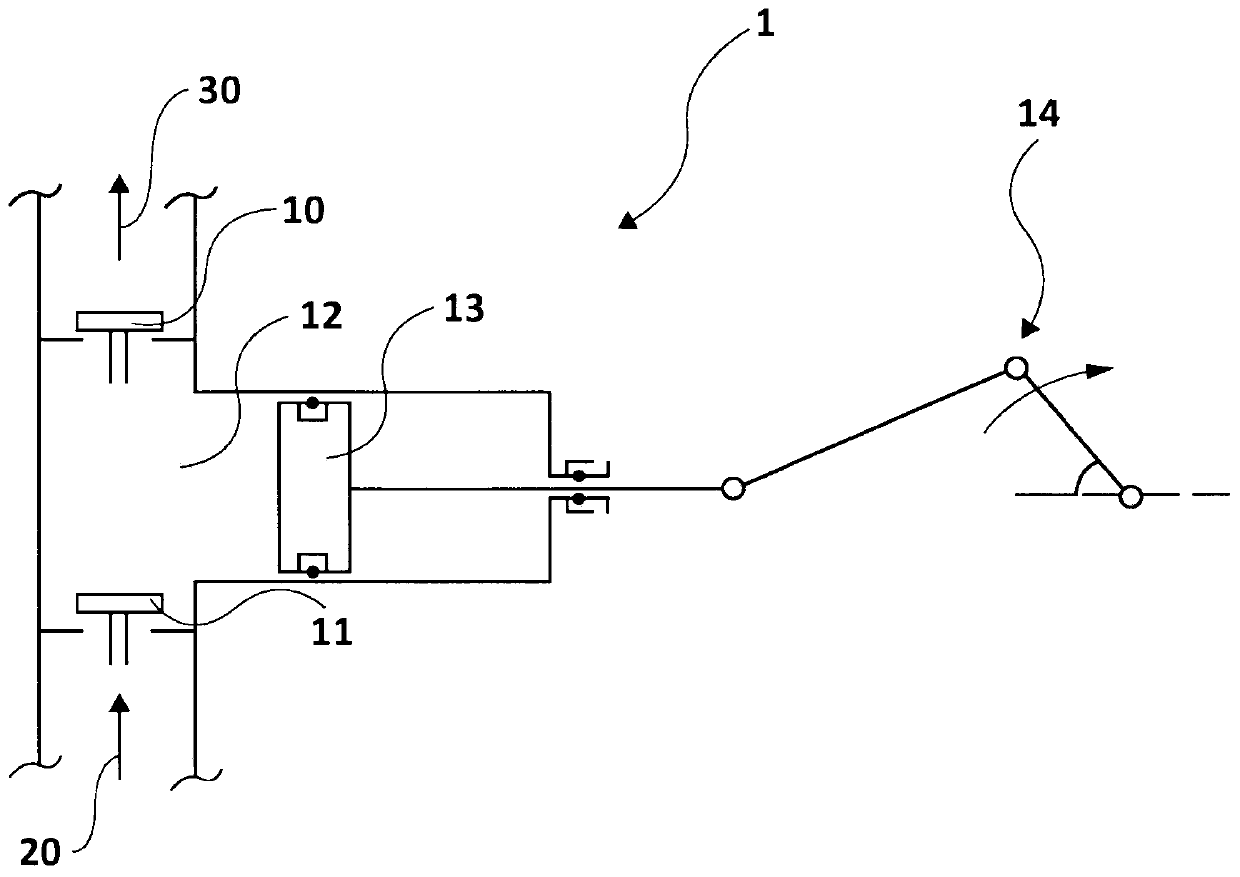

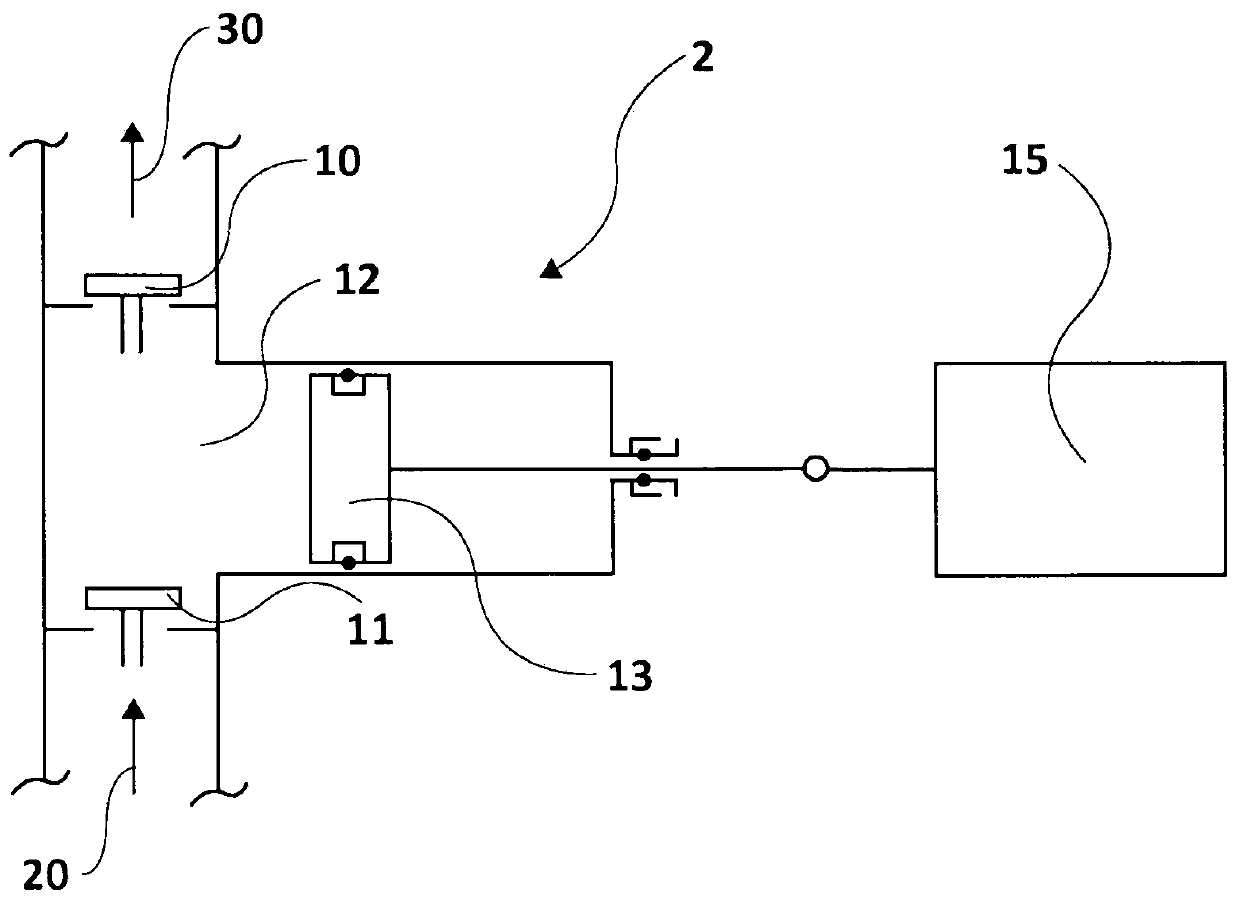

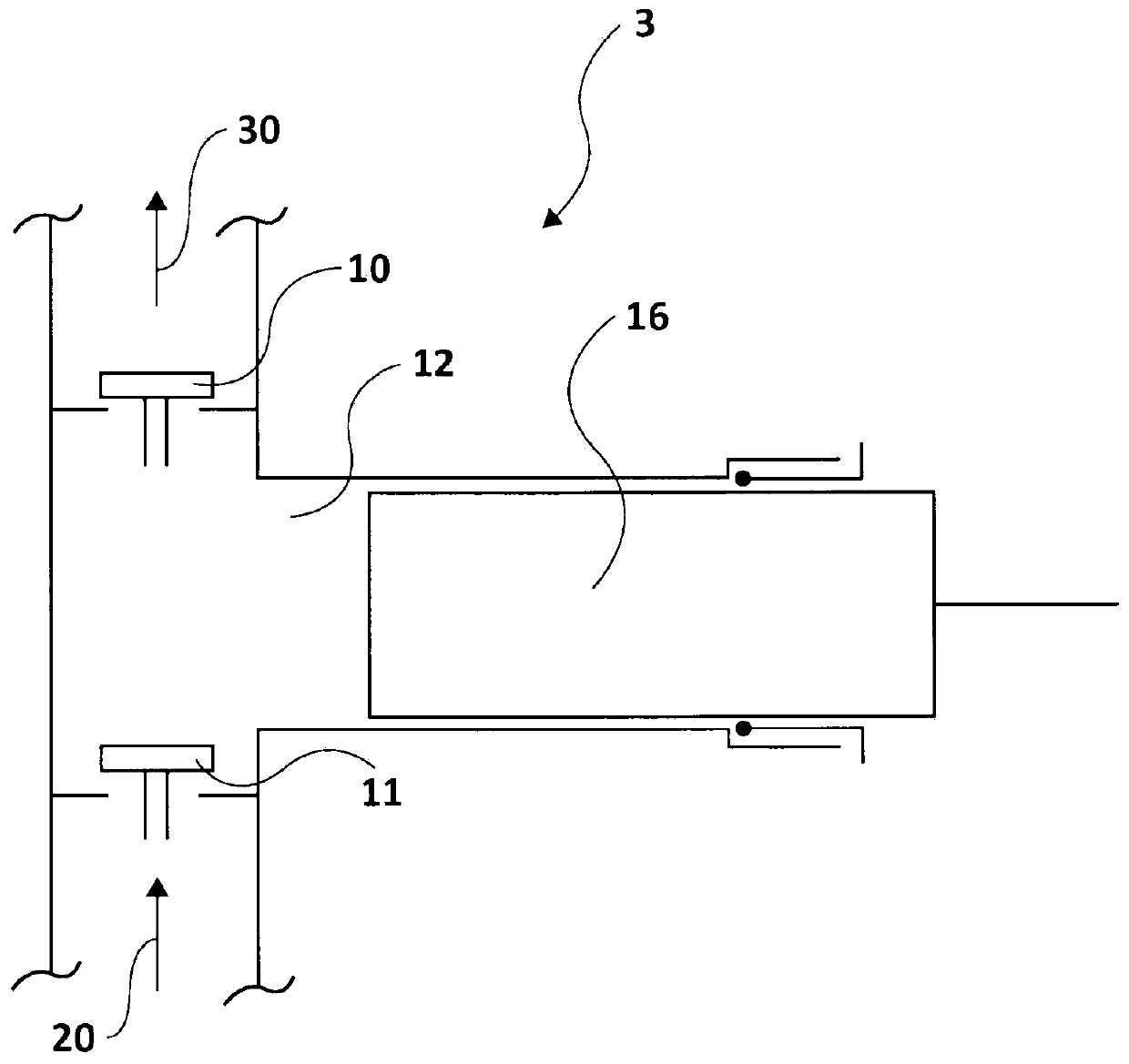

[0048] Starting from the inlet portion 53 , the pump body is then divided into two branches 61 and 62 . In a first of these branches, for example branch 61 , a first volume 511 of variable geometry is located, which is connected to said inlet part 53 by a first suction valve 611 and through a first suction valve 611 . A delivery valve 612 is connected to the outlet portion 54 .

[0049] In a second branch, such as branch 62 , a second variable geometry volume 521 is located, which is connected to said inlet portion 53 by a second suction valve 621 and connected by a second delivery valve 622 to the outlet section 54 .

[0050] The pump 5 according to the invention also comprises first means 51 for varying the volume of said first volume 511 of variable geometry, and second means ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com