Phase change heat accumulation fast cooling temperature control cup

A phase change heat storage and quick cooling technology, which is applied in the field of temperature control cups, can solve the problems of being unable to maintain for a long time, unable to achieve quick cooling, and unable to quickly drop to a suitable drinking temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

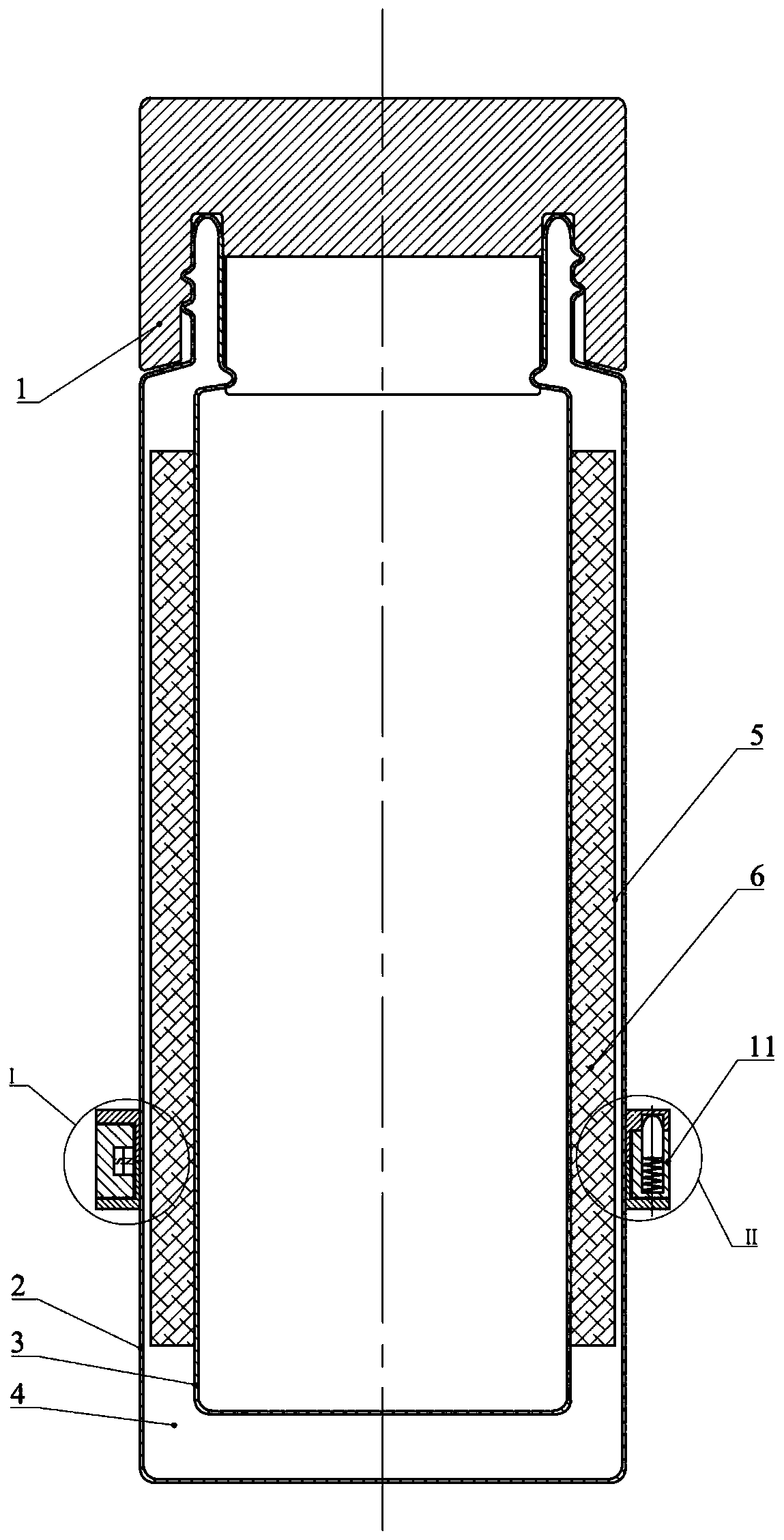

[0044] exist figure 1 and Figure 4 Among them, the phase change heat storage quick cooling temperature control cup of the present invention includes a cup body, multiple sets of phase change heat conduction structures and control switches. The cup body comprises a cup cover (1), an inner container (3) and an outer container (2), and a vacuum cavity (4) is formed between the inner container (3) and the outer container (2).

[0045]In this example, the multi-group phase-change heat-conducting structures include four groups, which are uniformly arranged in the vacuum chamber, and each group includes an arc-shaped heat-conducting shell (5), a phase-change material (6), a heat-conducting sheet (14) and a limiting sheet (15) , the phase change material (6) is encapsulated in the arc-shaped heat-conducting shell (5), the arc-shaped heat-conducting shell (5) is welded on the wall of the inner tank (3), and the outer arc of the arc-shaped heat-conducting shell (5) is connected with t...

Embodiment 2

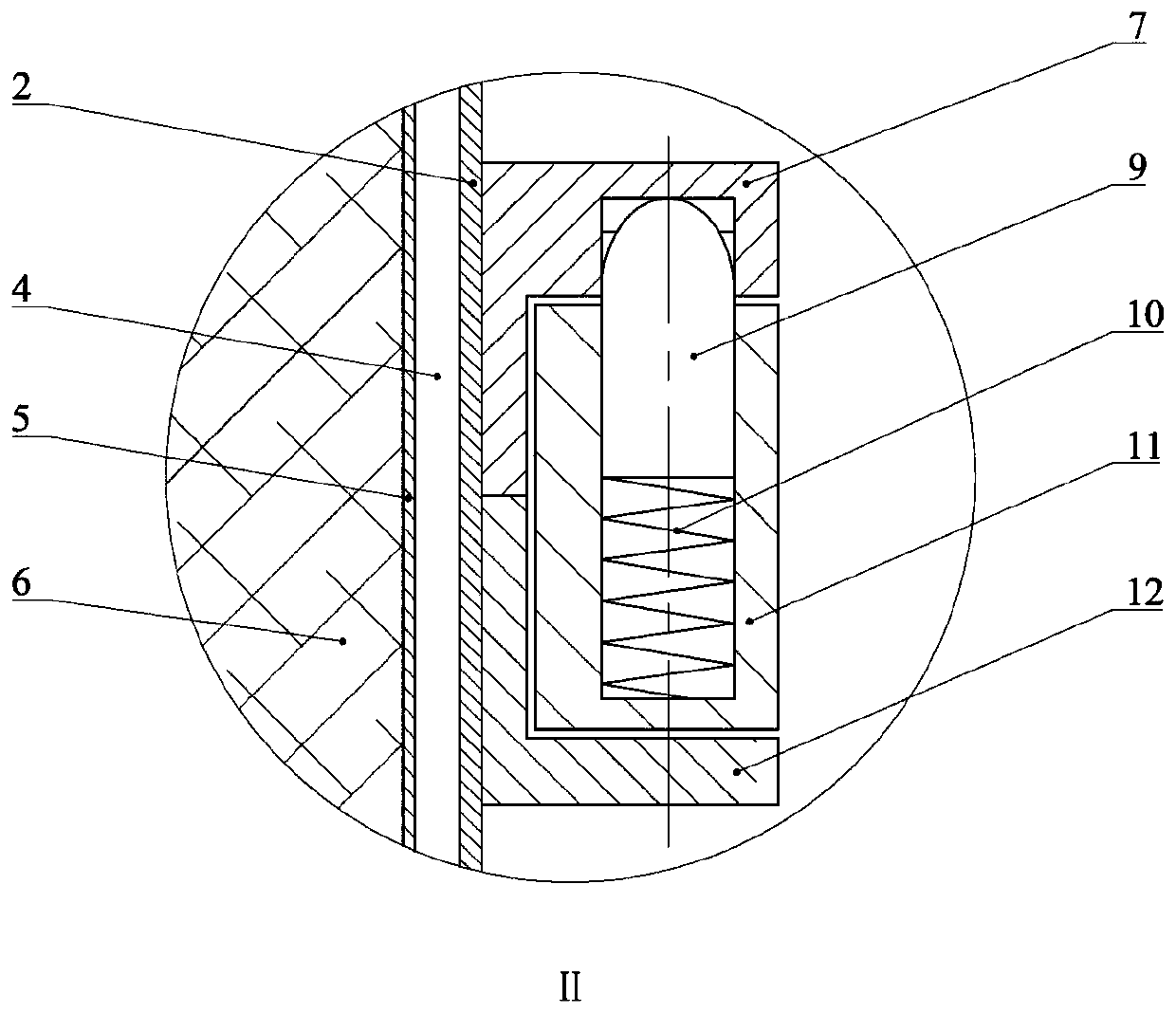

[0052] Optionally in this example, the control switch is also provided with a positioning structure, such as image 3 and Figure 7 As shown, it includes an upper fixing ring (7), a lower fixing ring (12) and a bullet buckle (9). Between the upper and lower fixing rings, the bullet buckle (9) is installed on the adjustment ring (11) through the compression spring (10), and is connected with the heat preservation position hole (17) and the heat dissipation position on the upper fixing ring (7) respectively. The location hole (18) locates the connection. Such as Figure 7 As shown, the external magnet (8) can only be switched in these two positions by the heat preservation position hole (17) and the heat dissipation position hole (18). The two positions are respectively used for the positioning of the adjusting ring in the two situations of heat dissipation and heat preservation.

Embodiment 3

[0054] This instance optionally, such as Figure 4 and Figure 6 As shown, the heat conduction sheet (14) is arc-shaped to match the shape of the outer container (2), and is a strip-shaped metal sheet, which adopts an elastic material with better thermal conductivity. The heat conduction sheet (14) and the outer container (2) When in contact state, the heat conducting sheet (14) will be close to the arc of the outer bladder (2).

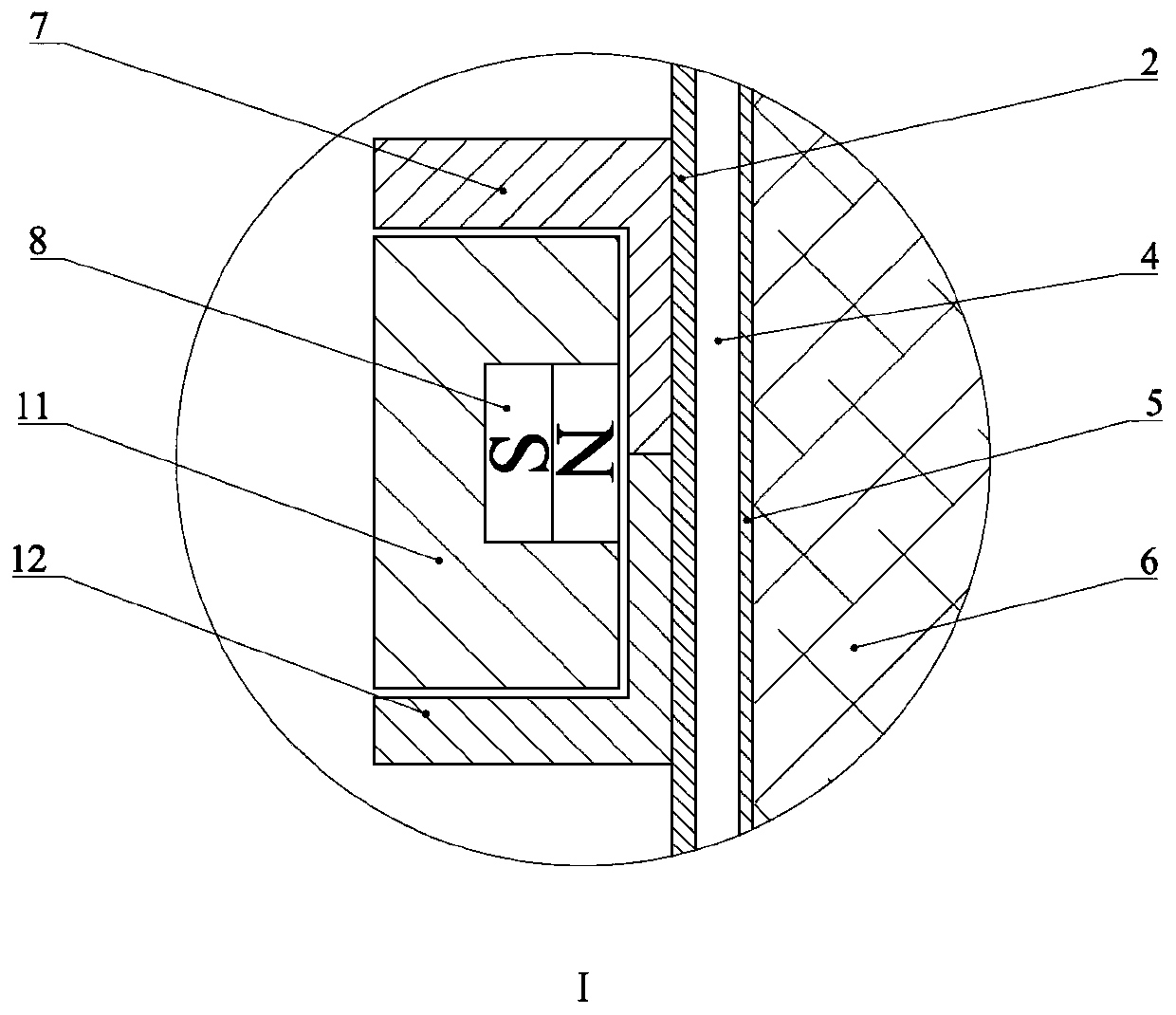

[0055] The heat conduction sheet (14) can make the heat conduction sheet (14) and the outer bladder (2) in a state of separation or contact through the action of the inner magnet (16) and the outer magnet (8).

[0056] The limiting sheet (15) is fixed on the inner container (3), and its position corresponds to abutting against the middle end or near the end of the heat conducting sheet (14).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com