Environment-friendly mechanical machining waste collection device

A technology for mechanical processing and waste collection, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of unfavorable collection and cleaning, unfavorable use of machine tools, etc., and achieve the effect of preventing iron filings from splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

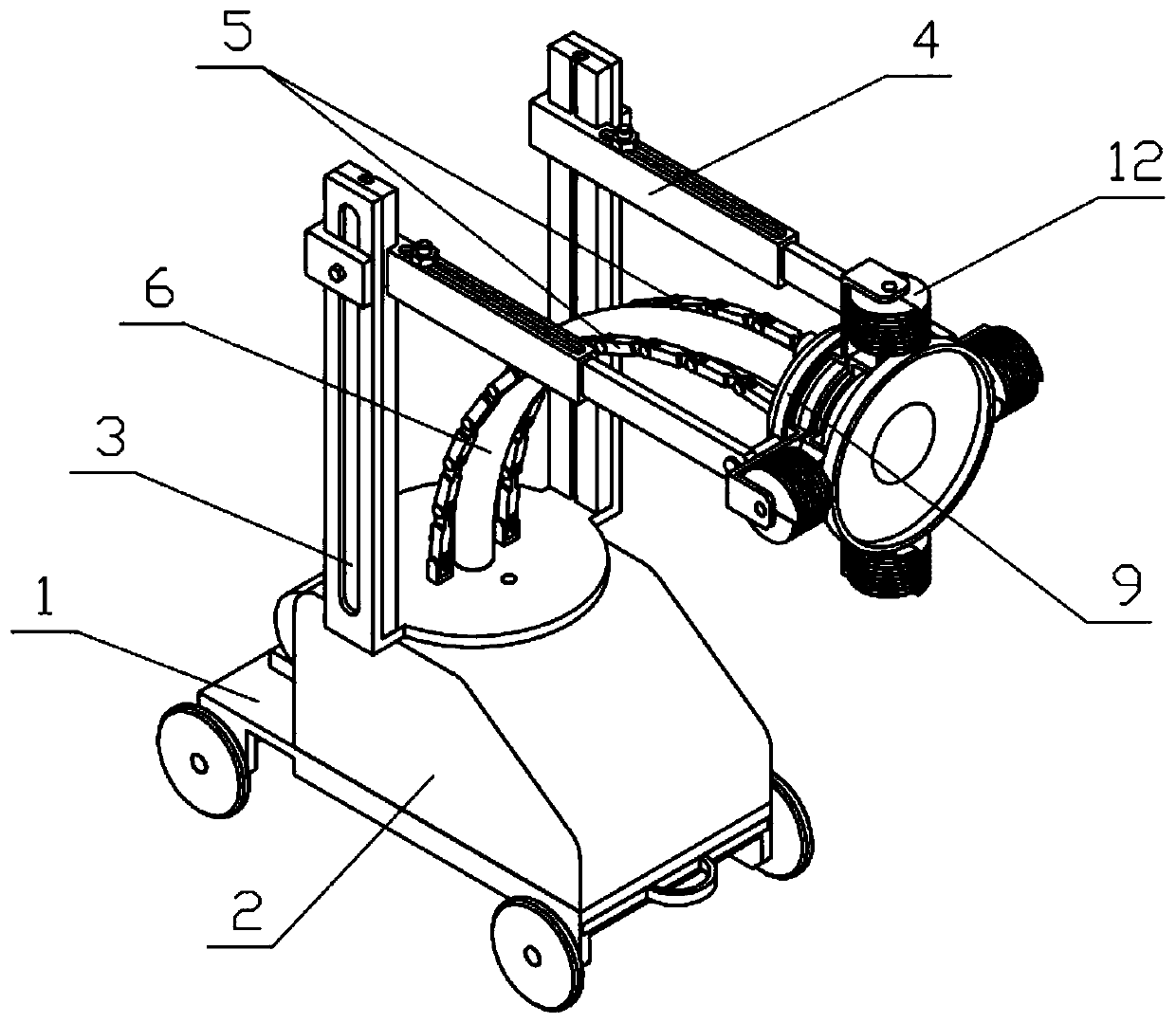

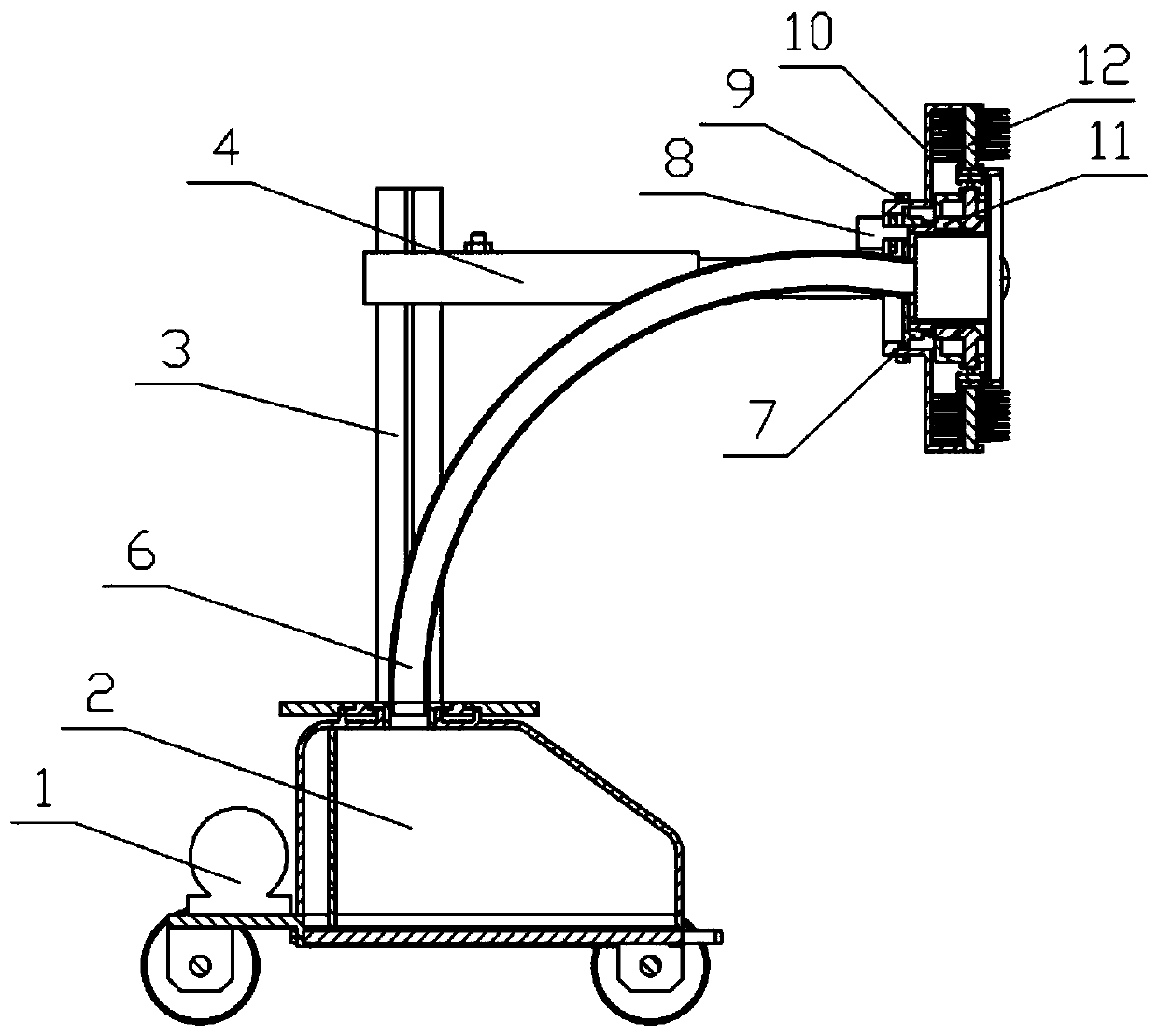

[0047] Combine below Figure 1-22 Describe this embodiment, an environment-friendly mechanical processing waste collection device, including a moving chassis 1, a collection box 2, a lifting support 3, a sliding support 4, a support mechanism 5, a collection pipe 6, a collection support 7, a rotating mechanism 8, a limit The rotating ring 9, the rotating bracket I10, the rotating bracket II11 and the collection mechanism 12, the collection box 2 is fixedly connected to the moving chassis 1, the moving chassis 1 is provided with a suction pump 1-2, the output end of the suction pump 1-2 and The collection box 2 is connected, and the lifting bracket 3 is rotatably connected to the collection box 2. There are two sliding brackets 4, and the two sliding brackets 4 are slidingly connected to the lifting bracket 3. There are two supporting mechanisms 5, and the two supporting mechanisms The two ends of 5 are respectively hinged on the lifting bracket 3 and the collection bracket 7, ...

specific Embodiment approach 2

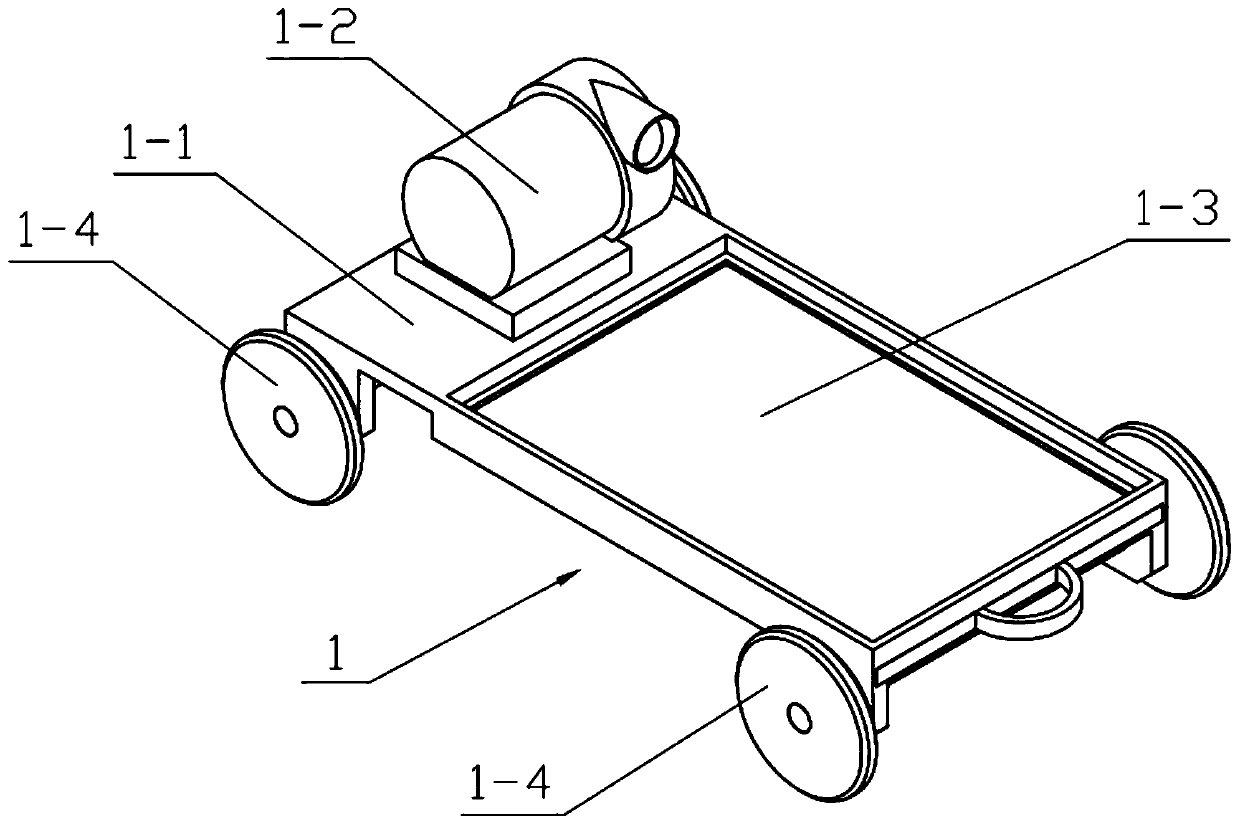

[0049] Combine below Figure 1-22 Describe this embodiment, this embodiment will further explain Embodiment 1, the said sports chassis 1 also includes a chassis body 1-1, a closing plate 1-3, a moving wheel 1-4 and a closing screw 1-5, the chassis body 1- 1 is slidably connected with a closing plate 1-3, the four corners of the chassis body 1-1 are rotatably connected with a motion wheel 1-4, two closing screws 1-5 are provided, and the two closing screws 1-5 are all worn The chassis body 1-1 is screwed to the closing plate 1-3.

specific Embodiment approach 3

[0051] Combine below Figure 1-22 Illustrate this embodiment, and this embodiment will further illustrate Embodiment 2. The collection box 2 includes a collection box 2-1, a rotating support platform 2-2, a rotating groove 2-3 and a screening plate 2-4, and collects The box body 2-1 is fixedly connected on the chassis body 1-1, and the collection box body 2-1 is fixedly connected with a rotating supporting platform 2-2, and the rotating supporting platform 2-2 is provided with a rotating groove 2-3, and the collecting box body 2-1 is fixedly connected with a screening plate 2-4, the output end of the suction pump 1-2 communicates with the collection box 2-1, and the screening plate 2-4 is located at the output end of the suction pump 1-2 and the rotating support platform Between 2-2, the rotating groove 2-3 and the rotating support table 2-2 are coaxially arranged; when in use, the suction pump 1-2 is started, so that the output end of the suction pump 1-2 generates suction, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com