Safety protection device for chamfering drill

A safety protection device and chamfering drill technology, which is applied in drilling repair, drilling tool accessories, transportation and packaging, etc. It can solve problems such as inappropriate chamfering force, affecting environmental sanitation, and affecting chamfering quality, so as to prevent iron filings Effects of splashing, reducing sanitation problems, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

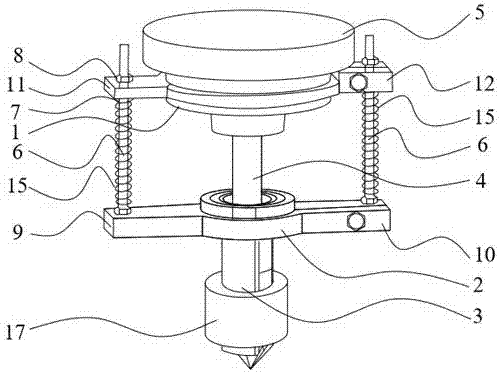

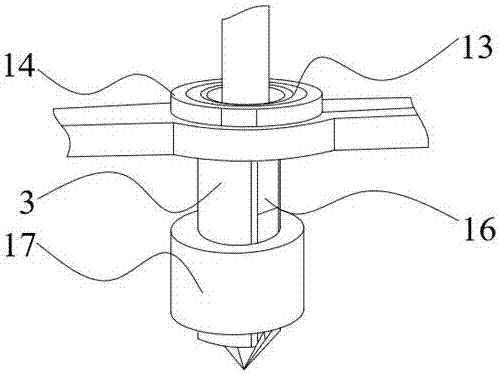

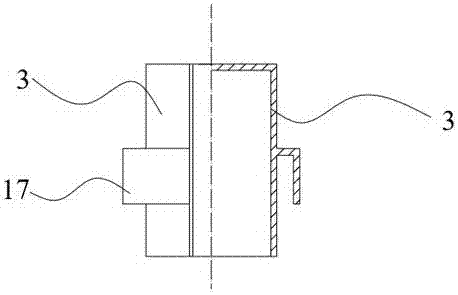

[0021] Such as Figure 1-3 As shown, a safety protection device for chamfering drills includes an upper clamping drum 1, a lower clamping drum 2, and a transparent cover 3. The centers of the upper clamping drum 1 and the lower clamping drum 2 overlap, and the upper clamping drum 1 and the lower clamping drum 2 Both are composed of the central part and the clamping earrings 11, 12, 9, 10 extending from the central part, the clamping earrings 11, 12, 9, 10 of the upper clamping drum 1 and the lower clamping drum 2 are connected by a connecting rod 6, and the upper clamping drum The drum 1 is connected to the jacket of the main shaft 5 of the drilling machine, and the center of the lower clamping drum 2 is provided with a moving ring 13 and a fixed ring 14. The moving ring 13 is connected with a transparent cover 3, and the drill bit 4 of the chamfering drill passes through the upper clamping drum 1 and the lower clamping drum. 2, the outside of the drill bit 4 of the chamfering...

Embodiment 2

[0024] The working principle of the chamfering drill safety protection device of the present invention is as follows: the device of the present invention connects the jacket of the drilling machine spindle 5 through the upper clamping drum 1, so that the centers of the upper clamping drum 1 and the lower clamping drum 2 overlap, and the upper clamping drum 1 and the lower clamping drum 2 are all made up of the central part and the clamping earrings 11, 12, 9, 10 extending out of the central part, forming a central hole for the drill bit 4 to pass through in the central part, and the clamping earrings 11 of the upper clamping drum 1 and the lower clamping drum 2 , 12, 9, 10 are connected by connecting rod 6, connecting rod 6 is a metal rod, and connecting rod 6 is covered with spring 15, and spring 15 plays a large buffering role, reducing the impact force of vibration on connecting rod 6, connecting rod 6. The top is threaded, and the upper nut 7 and the lower nut 8 are engaged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com