Railway shunting top-delivery operation smart control system

An intelligent control system and roof technology, applied in railway signaling and safety, can solve problems such as the inability to solve the real-time problem of shunting and roof delivery operations, and achieve the goal of transforming the working environment of workers, improving transmission efficiency, and promoting application value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

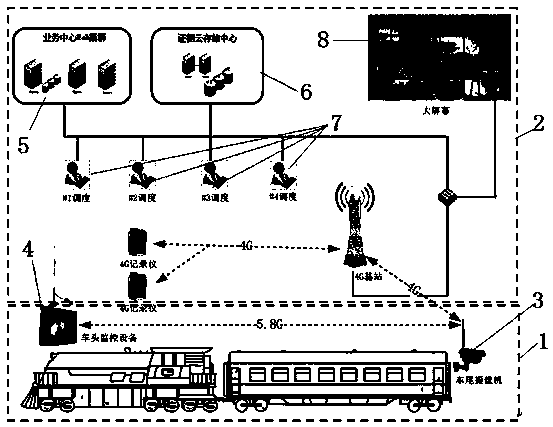

[0033] by attaching figure 1 It can be seen that the present invention relates to an intelligent shunting operation system for locomotives, which consists of two parts: a vehicle-mounted control system 1 and a ground control system 2, wherein the vehicle-mounted control system 1 includes an infrared supplementary light (not shown in the figure), It is composed of 5.8GHz image transmission module (not shown in the figure), rear camera 3, and locomotive cab monitoring equipment 4. The image data of the rear of the vehicle can be transmitted to the driver's cab through 5.8GHz wireless in real time, and the wireless transmission distance can reach more than 700 meters. The driver of the shunting locomotive can see the image of the rear of the vehicle through the screen. When the light is dark and at night, the module automatically turns on the infrared fill light for fill light, so that the line picture can be clearly seen at night.

[0034] The ground control system 1 is a set o...

Embodiment 2

[0045] The principle of the second embodiment is basically the same as that of the first embodiment, except that the structure is somewhat different. An intelligent locomotive shunting operation method is composed of an infrared supplementary light, a 5.8GHz image transmission module, a rear camera, and locomotive cab monitoring equipment. . The image data of the rear of the vehicle can be transmitted wirelessly to the cab in real time, and the wireless transmission distance can reach more than 700 meters. The driver of the shunting locomotive can see the image of the rear of the vehicle through the screen. When the light is dark and at night, the module automatically turns on the infrared fill light for fill light, so that the line picture can be clearly seen at night.

[0046] The real-time image transmission includes real-time transmission of the tail image of the shunting operation to the driver's cab of the shunting locomotive, which is convenient for the driver to judge ...

Embodiment 3

[0057] The basic principle of the third embodiment is the same as that of the first embodiment, except that the specific structure adopted is different. It is an intelligent locomotive shunting operation method based on computer vision and high-speed wireless video transparent transmission. The detachable information perception and processing equipment is installed on the vehicle, and the high-speed wireless data transmission method is used to transmit the shunting operation information at the rear of the vehicle to the driver's cab through the point-to-point wireless transmission between the information perception and processing equipment and the driver's cab. The driver's cab uses the wireless network transmission method to transmit the shunting operation and the driver's cab control operation information to the ground monitoring room to realize the intelligent shunting operation of the entire shunting operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com