Assembling and manufacturing method of bottom layer components of large-size polyurethane insulation box for LNG ship

A component assembly and LNG ship technology, applied in the direction of connecting components, material gluing, mechanical equipment, etc., can solve problems such as air residue, difficult to correct, and affect product quality, and achieve high-precision quality requirements, reduce misalignment, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

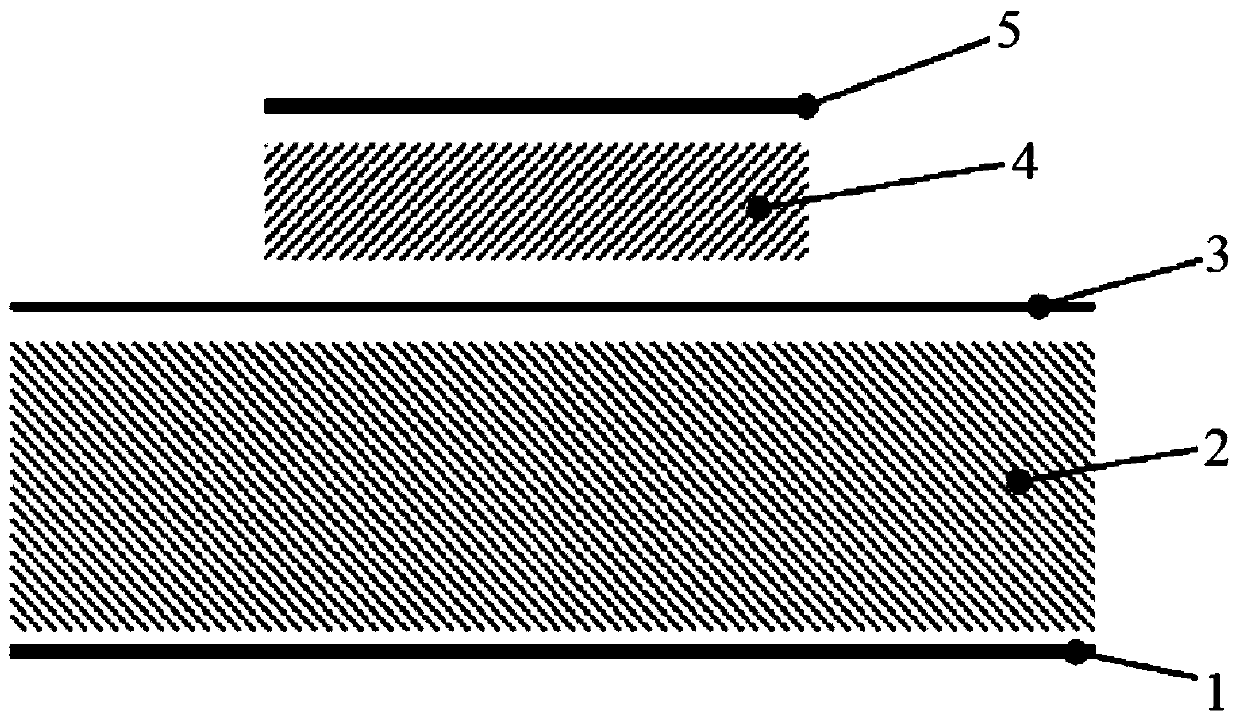

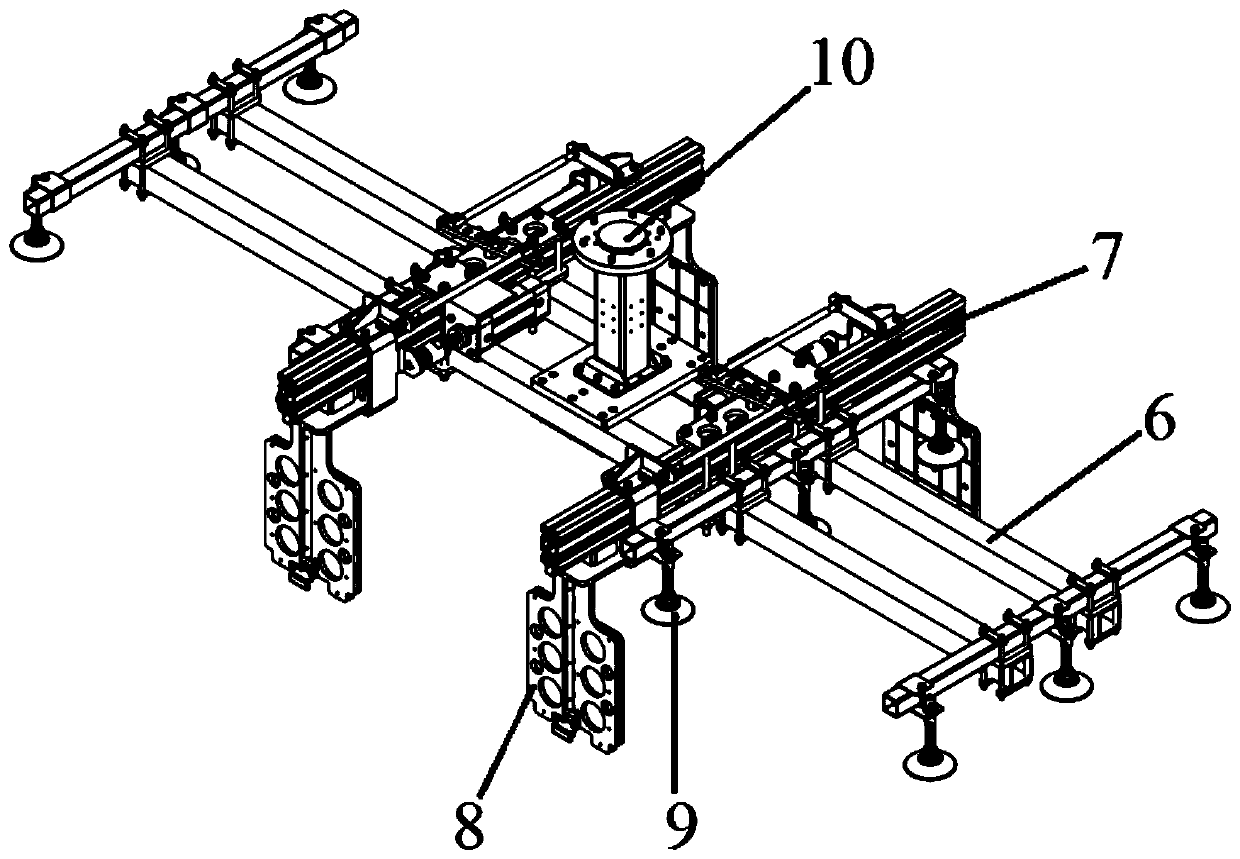

[0044]This embodiment designs an assembly and manufacturing method suitable for polyurethane insulation boxes of LNG ships, especially large-sized MARK III polyurethane insulation boxes, and utilizes the high flexibility of manipulators and industrial robots to accurately complete the lower layer of MARK III polyurethane insulation boxes For the automatic assembly of each component, the relevant information such as the production date, batch, model, etc. of polyurethane boards, plywood and other components required to enter the assembly area, as well as raw materials such as adhesives, is automatically entered into the mark of the corresponding insulation box and stored in the data system In the middle, and has been reliably tracked throughout the entire production process, which greatly improves the quality monitoring and traceability of the insulation box manufacturing process.

[0045] A method for assembling and manufacturing a large-sized polyurethane insulating box for li...

Embodiment 2

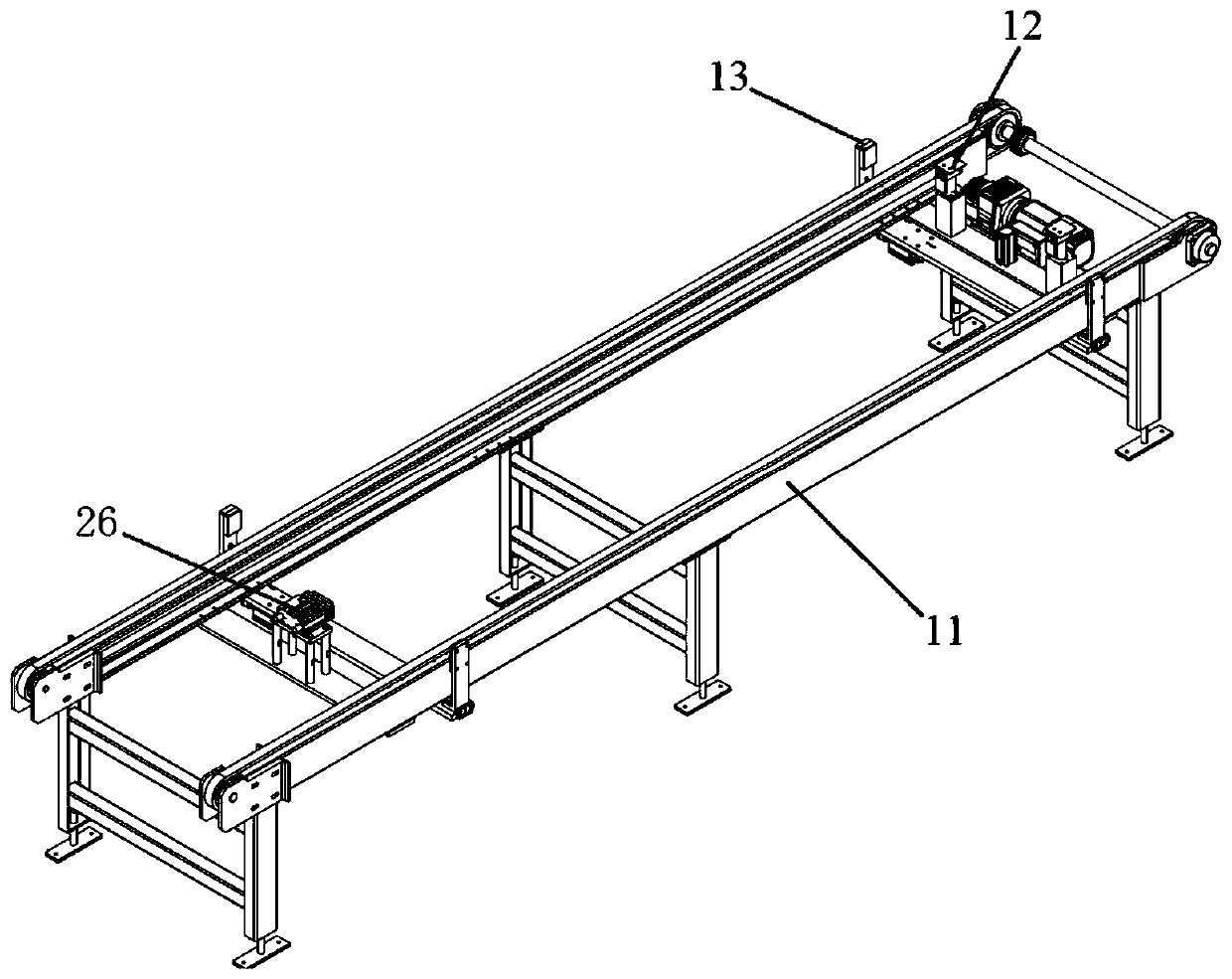

[0073] A method for assembling and manufacturing bottom parts of a large-size polyurethane insulating box for an LNG ship, comprising the following steps:

[0074] (1) Code scanning process, scan the corresponding code of the polyurethane board or plywood, and input it into the system;

[0075] (2) Feeding process, placing the polyurethane board or plywood on the feeding conveyor line of the automatic glue spraying station;

[0076] (3) Automatic gluing process, cleaning the polyurethane board or plywood on the feeding conveyor line and then gluing the surface;

[0077] (4) The bottom part assembly process, the bottom plywood and the bottom polyurethane board of the polyurethane insulation box are assembled;

[0078] (5) RSB assembly process, the hard three-in-one sheet is assembled on the bottom polyurethane board;

[0079] (6) RSB rolling process, the upper surface of the hard three-in-one sheet on the bottom polyurethane plate is rolled;

[0080] (7) The overall correcti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com