Heavy pre-pressing high-rigidity narrow linear guide rail device

A linear guide, high rigidity technology, applied in the direction of linear motion bearings, bearings, shafts and bearings, etc., can solve the problems of increased frictional resistance of linear guides, affecting the accuracy of product processing, insufficient rigidity of linear guides, etc., to reduce the driving force. The effect of energy, smooth operation, increased flexibility and machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In view of the deficiencies in the prior art, the case has been studied for a long time and a large amount of practice, and the technical scheme of the present invention can be proposed. The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

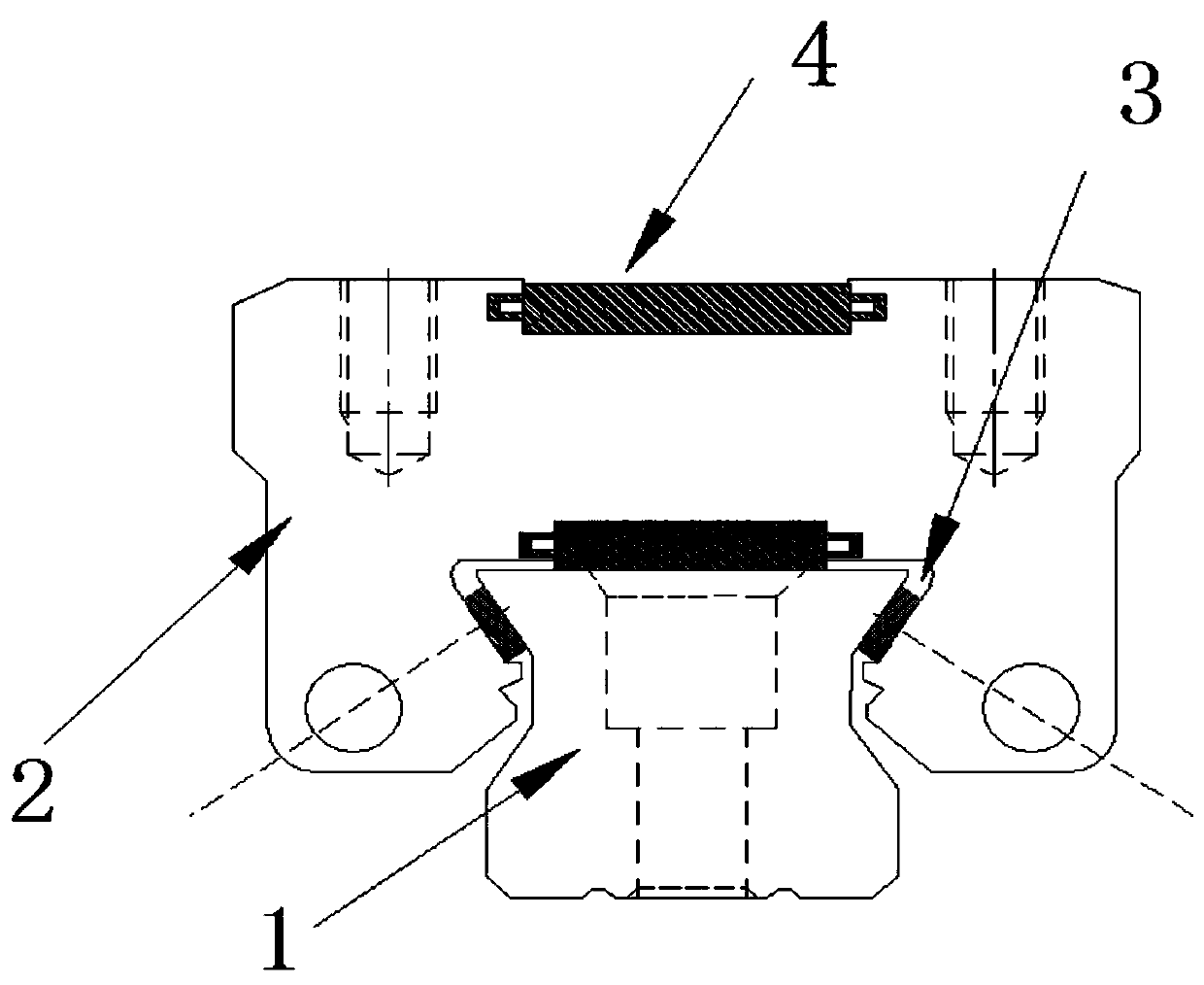

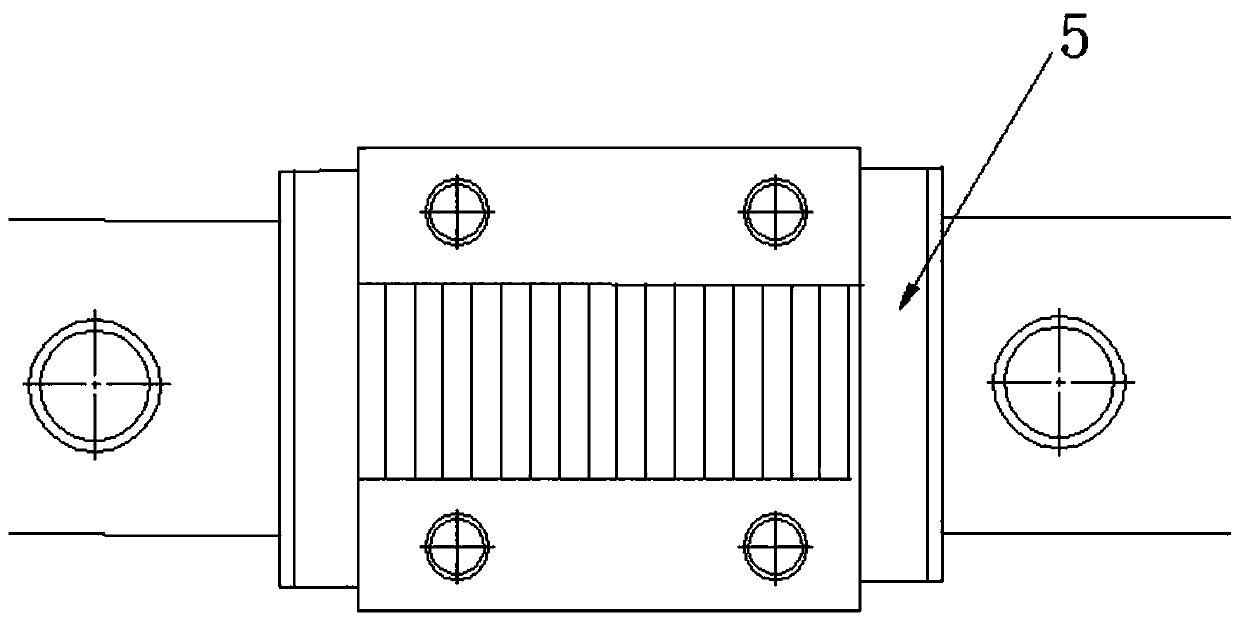

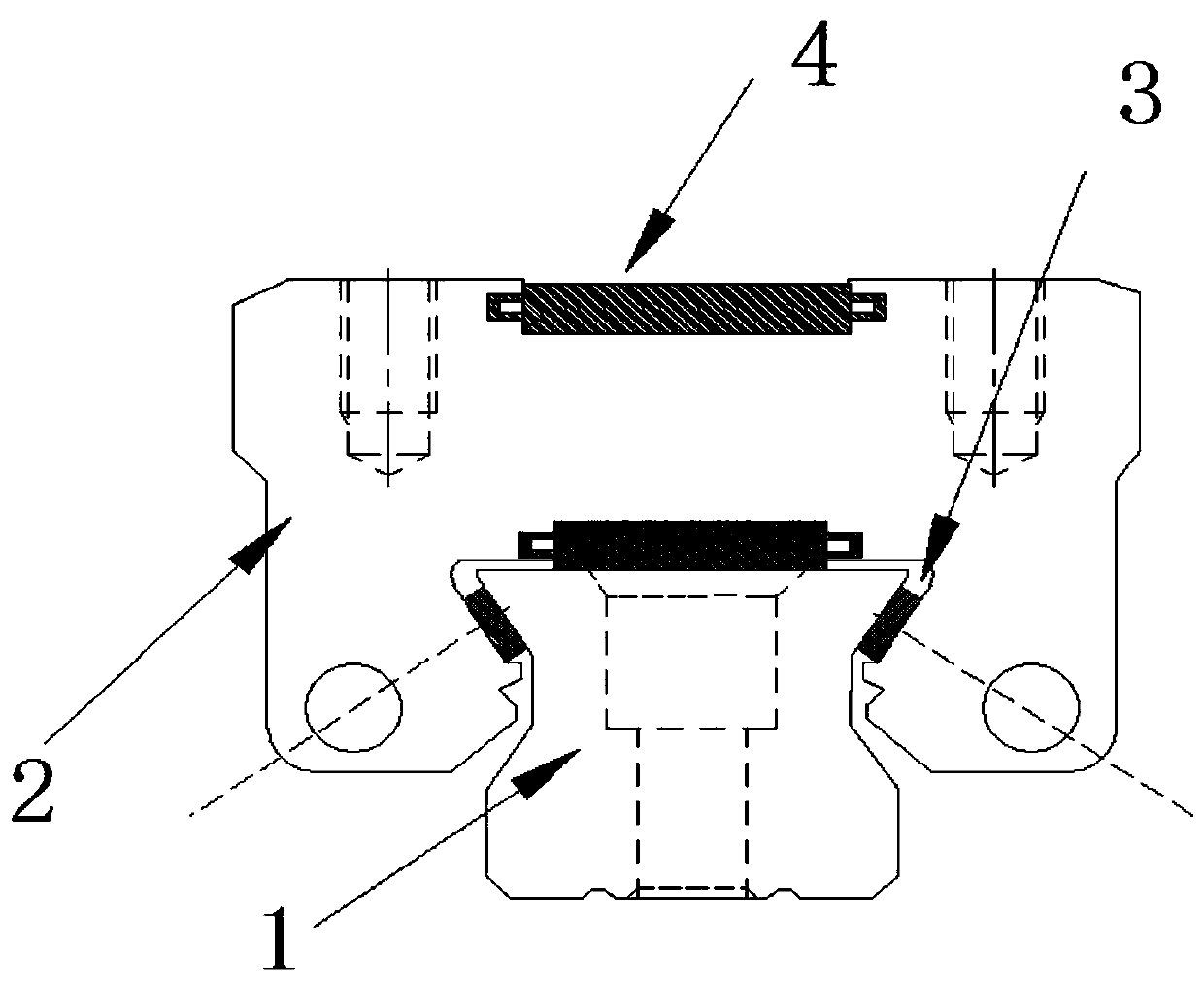

[0021] figure 1 It is a cross-sectional view of a heavy preloaded high rigidity narrow linear guideway device; figure 2 It is a schematic diagram of the structure of a heavy preloaded high rigidity narrow linear guideway device. Such as figure 1 and figure 2 As shown, a heavy preloaded high-rigidity narrow linear guide rail device provided in the embodiment of the present invention includes: a guide rail 1 and a slider 2 matched with it, and there are a row of small rollers on the left and right sides of the slider 2 3. There is a row of large rollers 4 located around slider 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com