Power generator

A generator and winding technology, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve problems affecting generator output, stator rotating magnetic field imbalance, generator burnout, etc., to reduce mechanical resonance and operating noise, improve The effect of power supply reliability and reduction of waveform distortion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

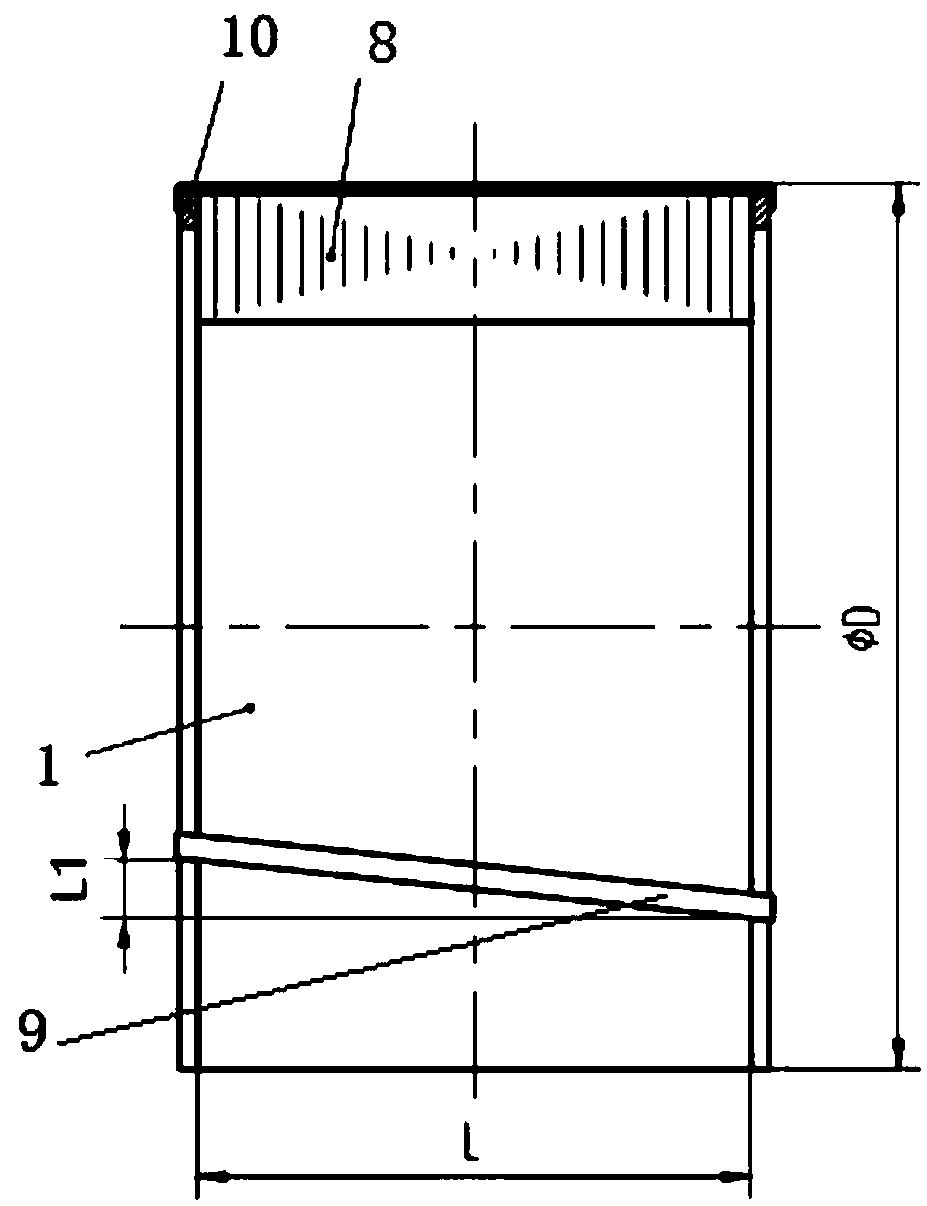

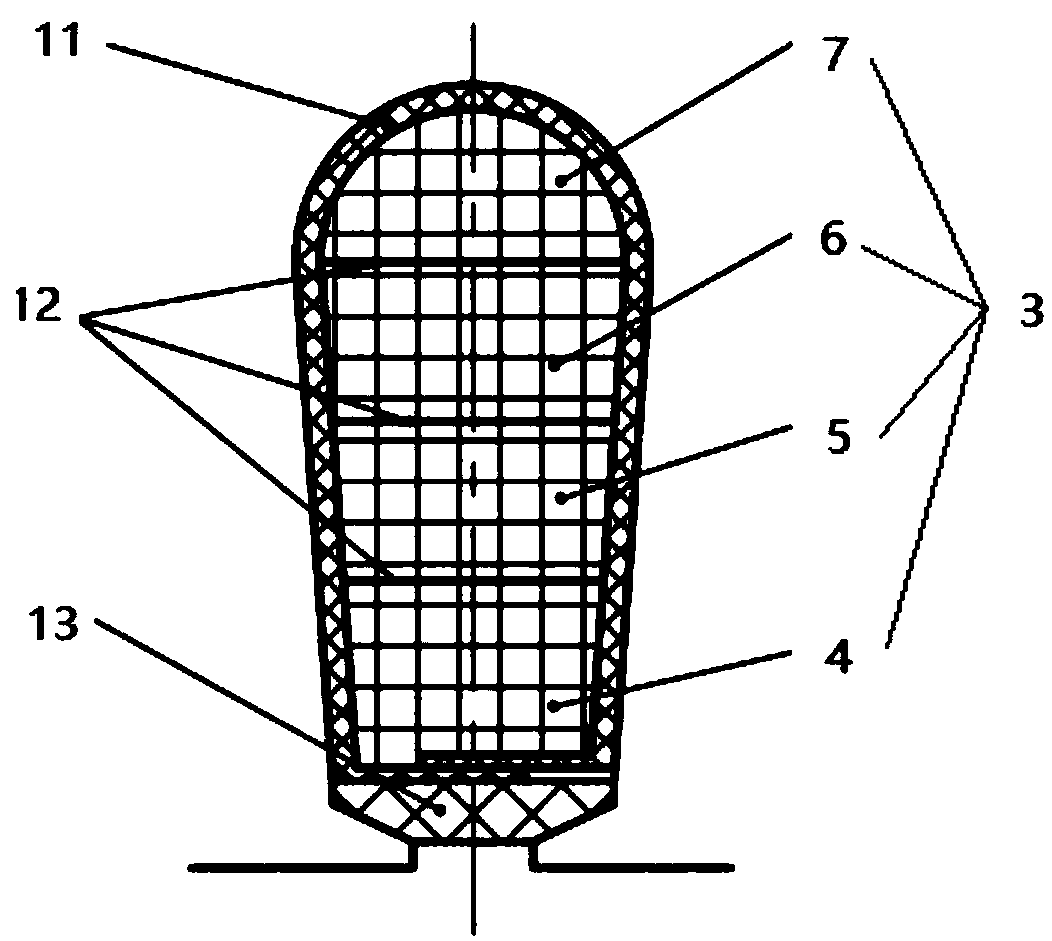

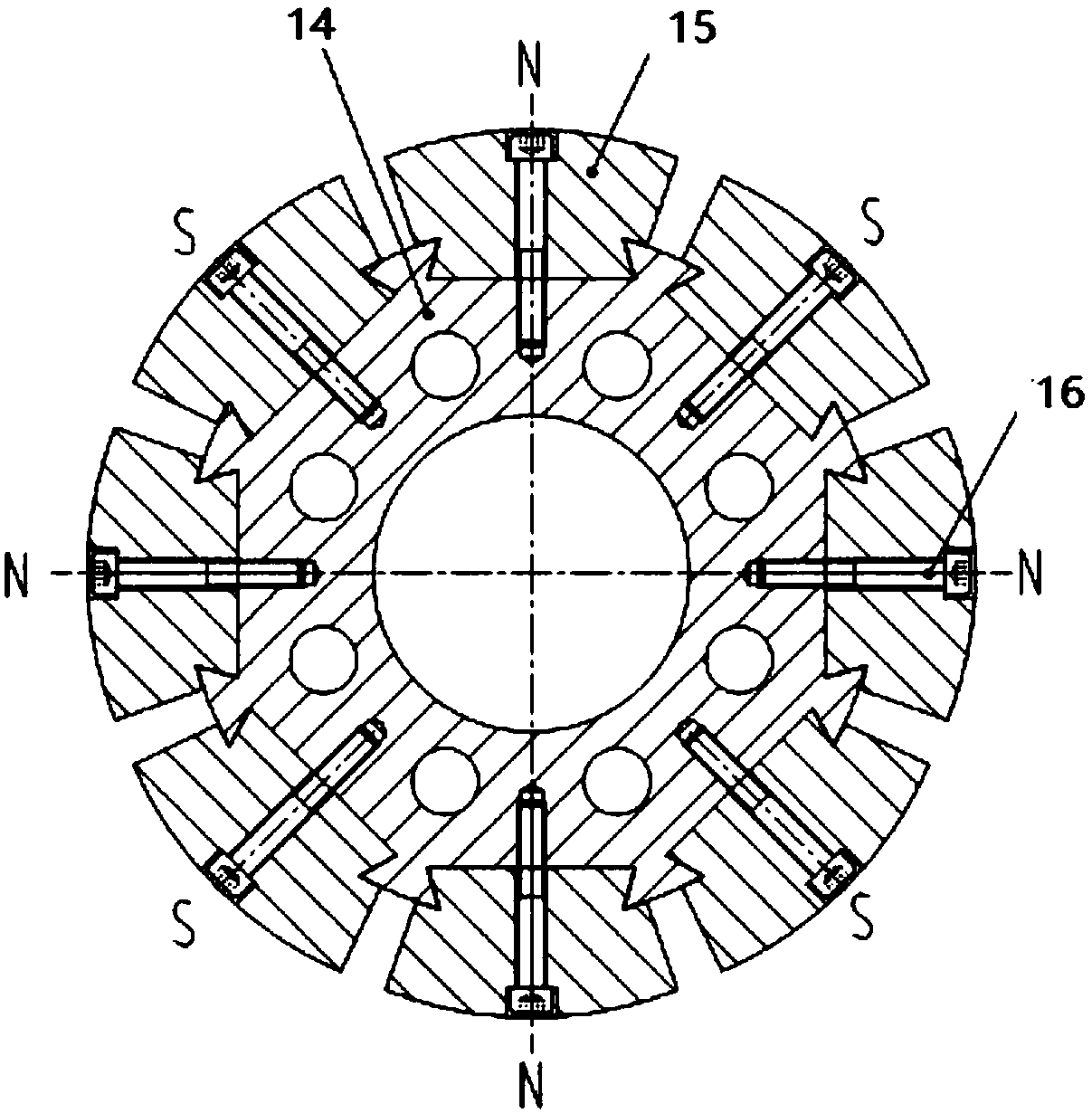

[0029] An embodiment of the present invention provides a generator, including a stator and a rotor, such as figure 1 , figure 2 and Figure 4 As shown, the stator includes: a stator core 1 and a stator winding 3. The inner circle of the stator core 1 is formed with a plurality of evenly distributed and obliquely arranged stator slots 2; Layer winding 4, second layer winding 5, third layer winding 6 and fourth layer winding 7, first layer winding 4 and second layer winding 5 form the first set of three-phase windings, third layer winding 6 and fourth layer The winding 7 forms the second set of three-phase windings, and the slot numbers of the initial stator slots 2 of the first set of three-phase windings and the second set of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com