Electrodeposited diamond dresser for forming threaded abrasive tool for gear grinding and method for manufacturing same

A diamond and thread-like technology, applied in the field of electrodeposited diamond dressers, can solve problems such as shortened life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] Hereinafter, embodiments of the electrodeposition diamond dresser for forming a threaded grindstone for gear grinding according to the present invention will be described with reference to the drawings.

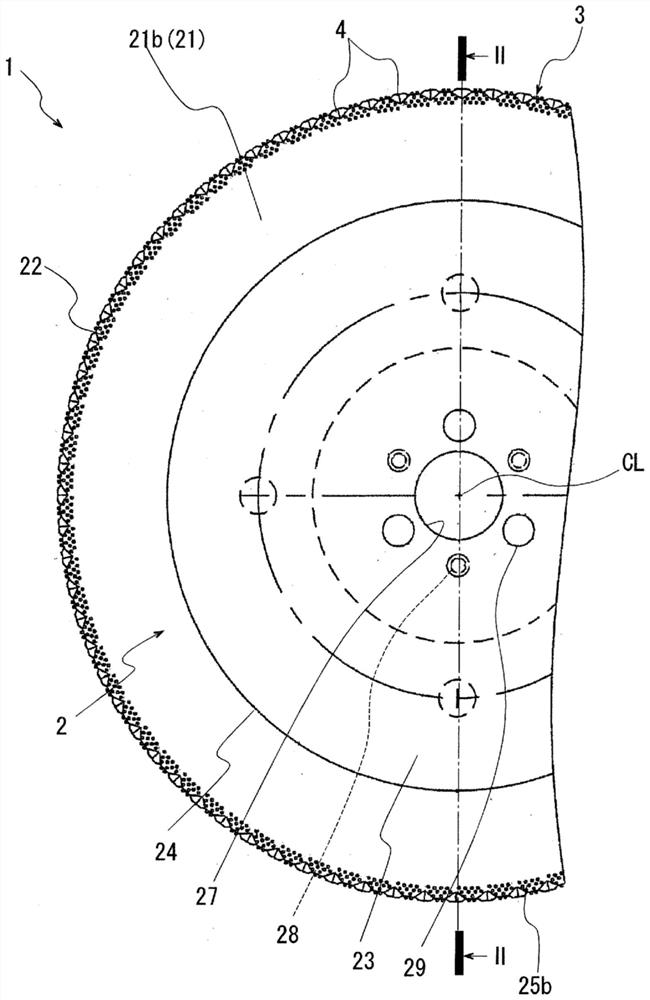

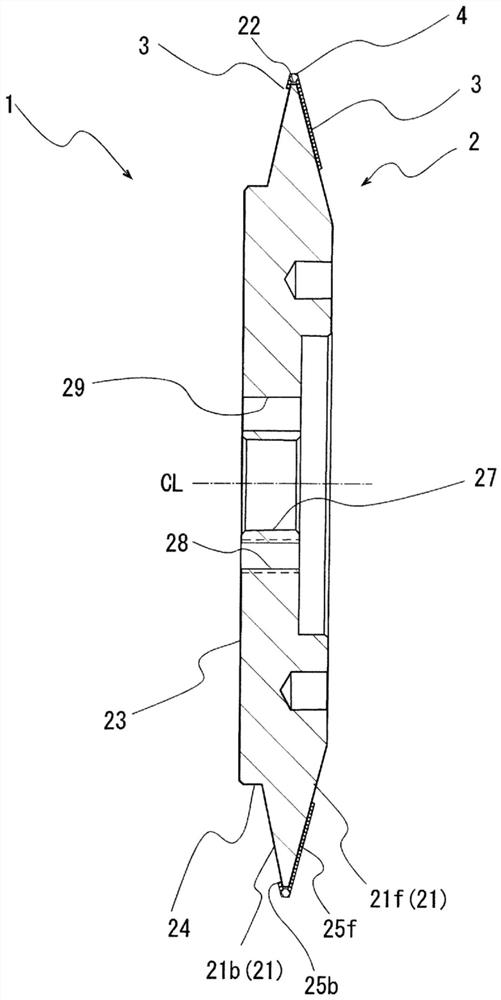

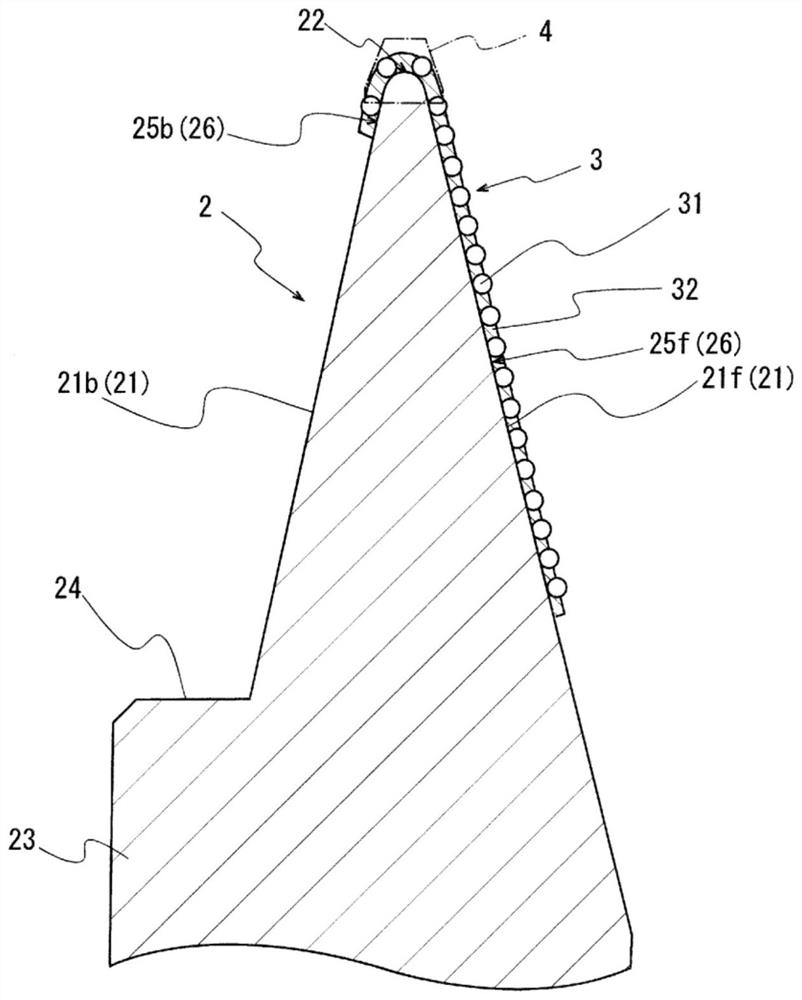

[0038] Such as figure 1 as well as figure 2 As shown, the electrodeposited diamond dresser 1 for molding includes a grinding wheel 2 , a diamond abrasive grain layer 3 provided on the grinding wheel 2 , and an octahedral single crystal diamond abrasive grain 4 provided on the outer peripheral surface 22 of the grinding wheel 2 .

[0039] (Grinding wheel)

[0040] Such as figure 1 as well as figure 2 As shown, the grindstone 2 is, for example, a steel member, and has tapered surfaces 21 (surface tapered surface 21f, inner tapered surface 21b) that become thinner toward the outer periphery on both front and back surfaces, and is formed in a disc shape. As quenched and tempered steel parts, quenched and tempered steel (SUJ) etc. are used, for example. The tapered s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com