Negative electrode, battery, battery pack, electronic device, electric vehicle, electric storage device, and electric power system

A technology for power storage devices and electronic equipment, applied in the field of power systems, which can solve problems such as the decline in battery characteristics such as charge and discharge efficiency, high battery capacity, and high output characteristics, and achieve the effect of suppressing the increase in internal resistance and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

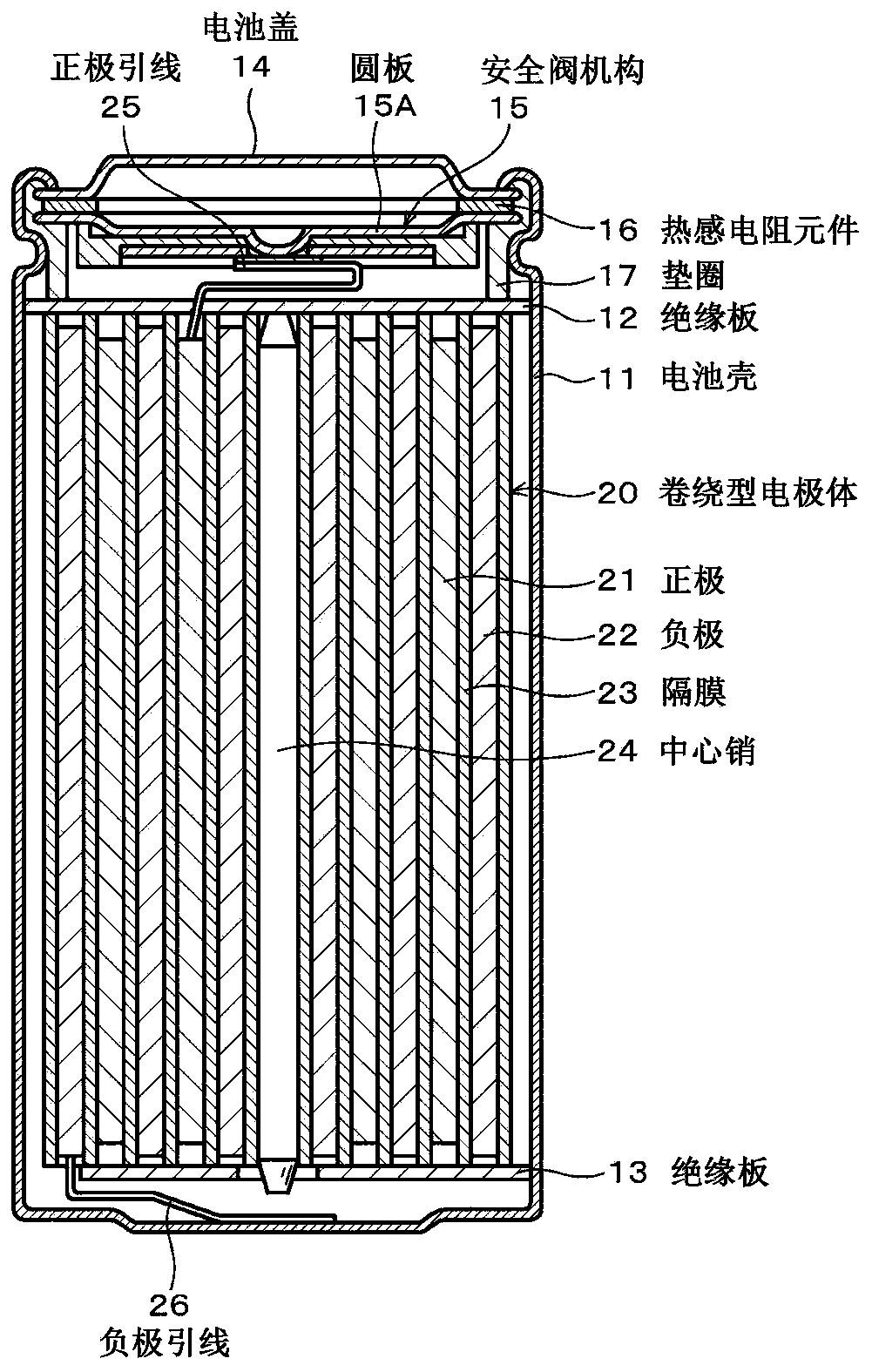

[0030] 1 First Embodiment (Example of Cylindrical Battery)

no. 2 approach

[0031] 2 Second Embodiment (Example of Laminated Film Type Battery)

no. 2 approach >

[0160] [composition of the battery]

[0161] image 3 It is an exploded perspective view showing a configuration example of the secondary battery according to the second embodiment of the present technology. This secondary battery is called a so-called flat type or a square type, and is a secondary battery in which a wound electrode body 30 to which a positive electrode lead 31 and a negative electrode lead 32 are attached is housed inside a film-shaped exterior member 40, so that it is compact. Minimization, weight reduction and thinning are possible.

[0162] The positive electrode lead 31 and the negative electrode lead 32 are led out from the inside of the exterior member 40 toward the outside, for example, in the same direction. The positive electrode lead 31 and the negative electrode lead 32 are made of metal materials such as aluminum, copper, nickel, or stainless steel, respectively, and are each in the shape of a thin plate or a mesh.

[0163] The exterior member ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com