Rotor for rotating electrical machine and method for manufacturing rotor for rotating electrical machine

A technology for rotating electrical machines and rotors, which is applied in the field of rotors for rotating electrical machines, and can solve problems such as difficult and reduce cogging torque and torque fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

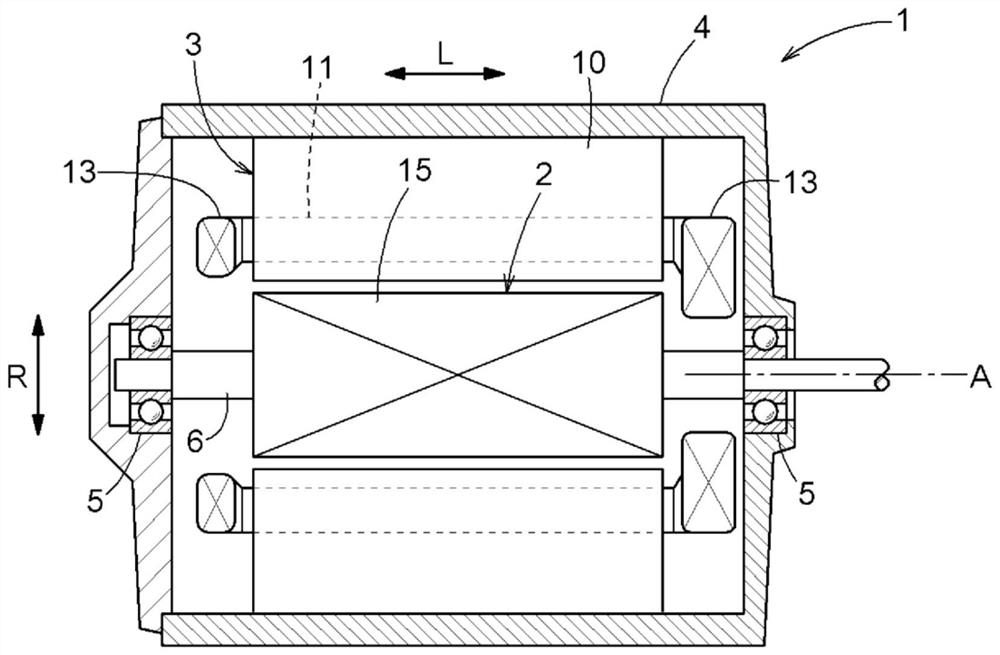

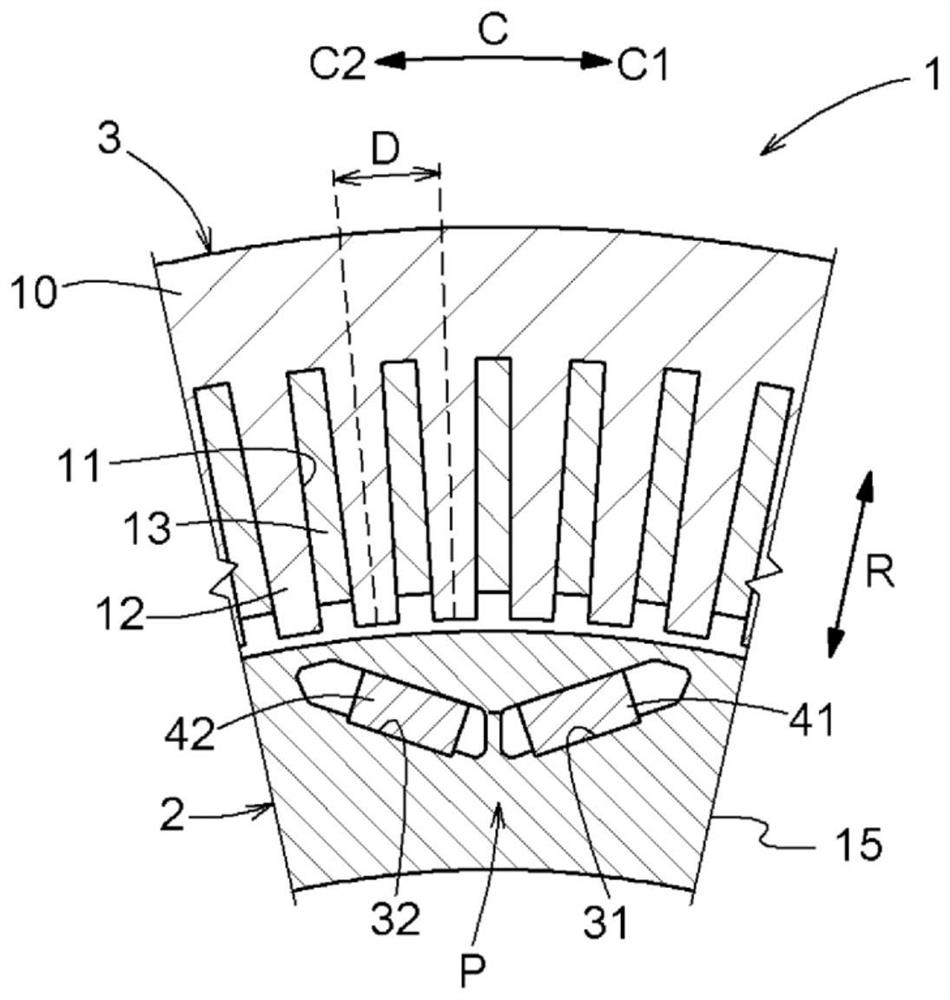

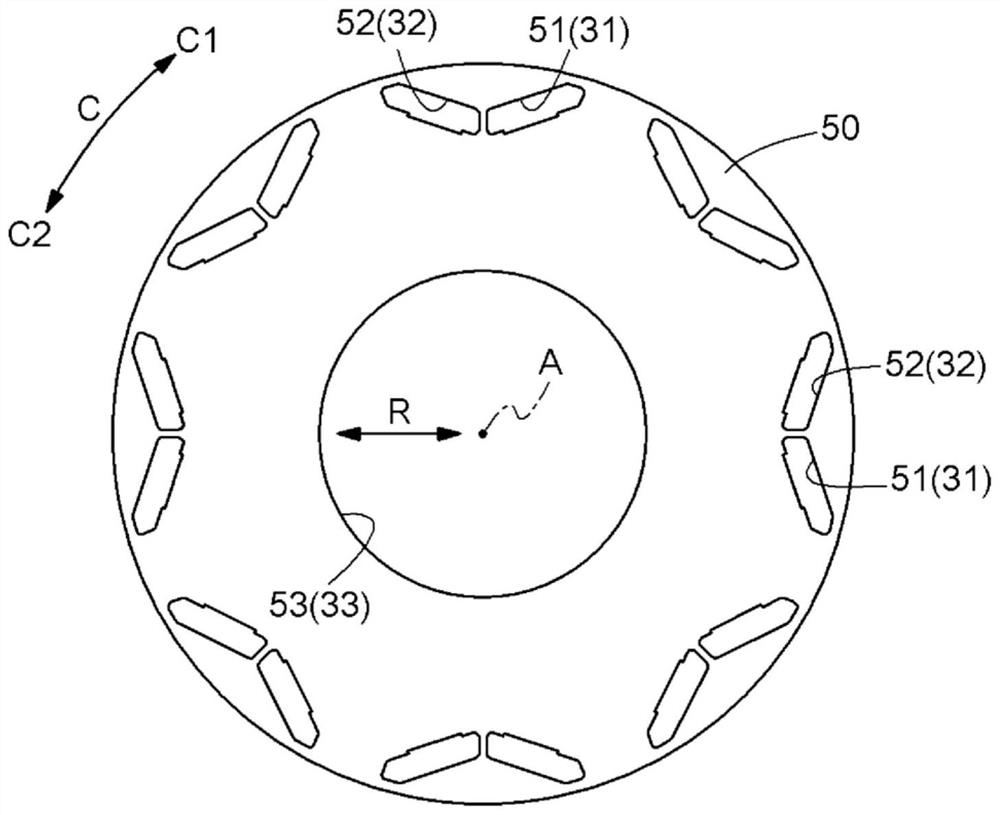

[0027] Embodiments of the rotor for a rotating electric machine and its manufacturing method will be described with reference to the drawings. In addition, in the following description, "axial direction L", "radial direction R", and "circumferential direction C" refer to the axis A (refer to figure 1 etc.) as the benchmark definition. The axis A is an imaginary axis, and the rotor 2 rotates around the axis A. And, if Figure 4 etc., let one side in the axial direction L be referred to as the "first axial side L1", and the other side in the axial direction L (the side opposite to the first axial side L1) be referred to as the "second axial side". side L2". In addition, one side in the circumferential direction C is referred to as "the first side C1 in the circumferential direction", and the other side in the circumferential direction C (the side opposite to the first side C1 in the circumferential direction) is referred to as "the second side C2 in the circumferential direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com