High-power suspension type permanent magnet direct drive motor

A permanent magnet direct drive and suspension technology, applied to synchronous motors with stationary armatures and rotating magnets, electric components, electrical components, etc., can solve problems such as difficult loading and unloading, and achieve the effect of improving the convenience of loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

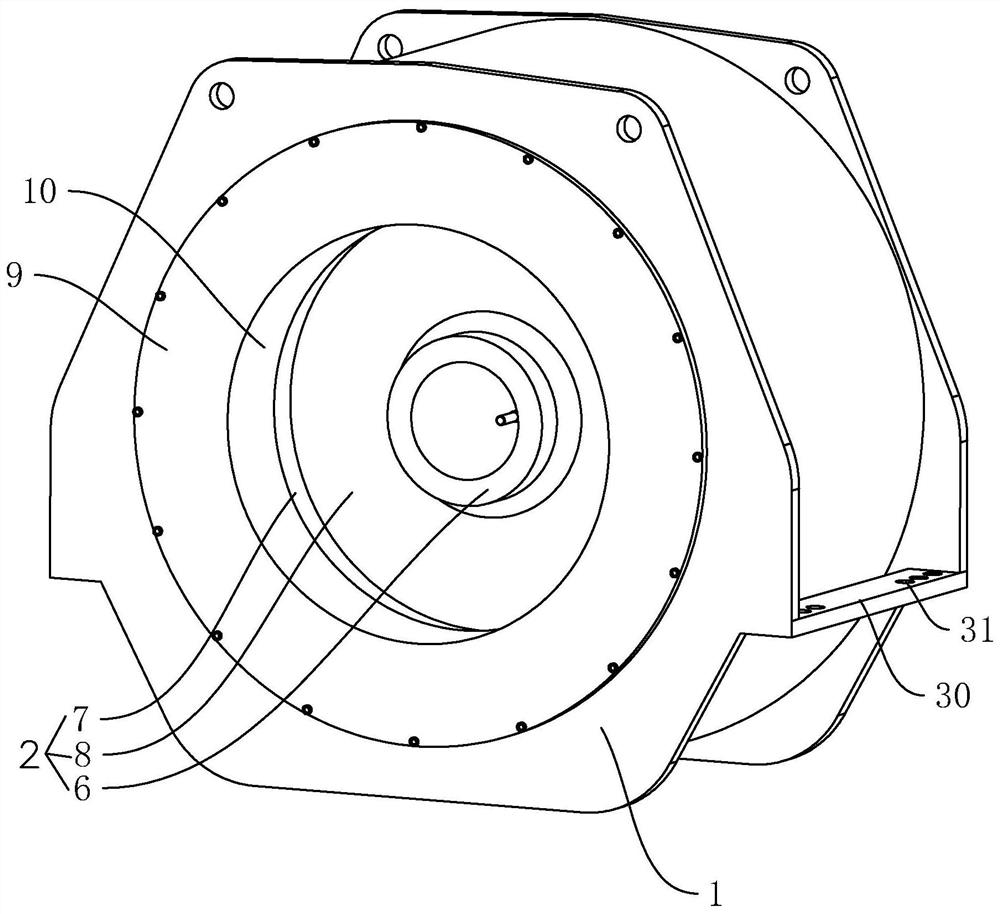

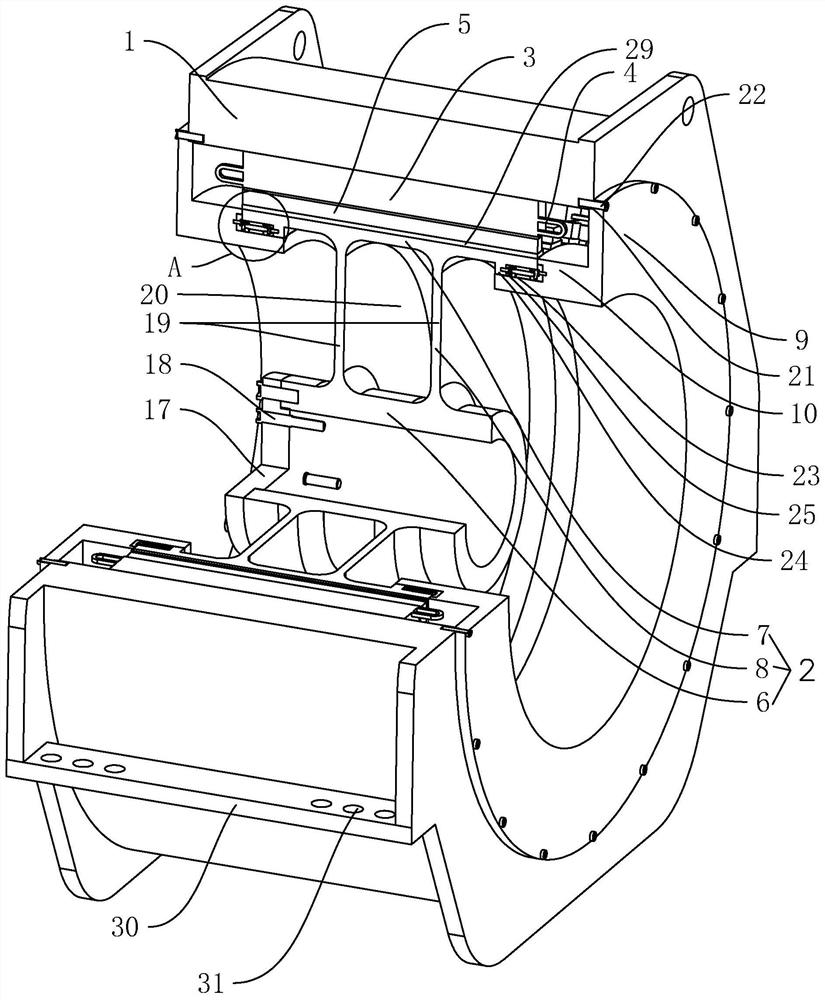

[0032] A high-power suspended permanent magnet direct drive motor, such as figure 1 , figure 2 , image 3 As shown, it includes a stator base 1 and a driving rotor bracket 2 rotatably connected to the stator base 1. A plurality of stator cores 3 are installed at equal angles on the inner circumference of the stator base 1. The stator cores 3 are provided with motor windings. 4. A plurality of permanent magnet poles 5 are installed at equal angles on the outer circumferential surface of the driving rotor bracket 2. The driving rotor bracket 2 includes a central sleeve 6, a connecting ring 7 coaxially arranged with the central sleeve 6, and a connecting ring for connecting The connecting part 8 between the central sleeve 6 and the connecting ring sleeve 7, the central sleeve 6 is used to connect the input shaft of the equipment to be supplied with kinetic en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com