Method for artificially synthesizing platelets in vitro in fluid movement mode

A fluid movement and artificial synthesis technology, applied in the field of machinery, can solve problems such as ineffective platelet transfusion and lack of platelet sources, and achieve a huge output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

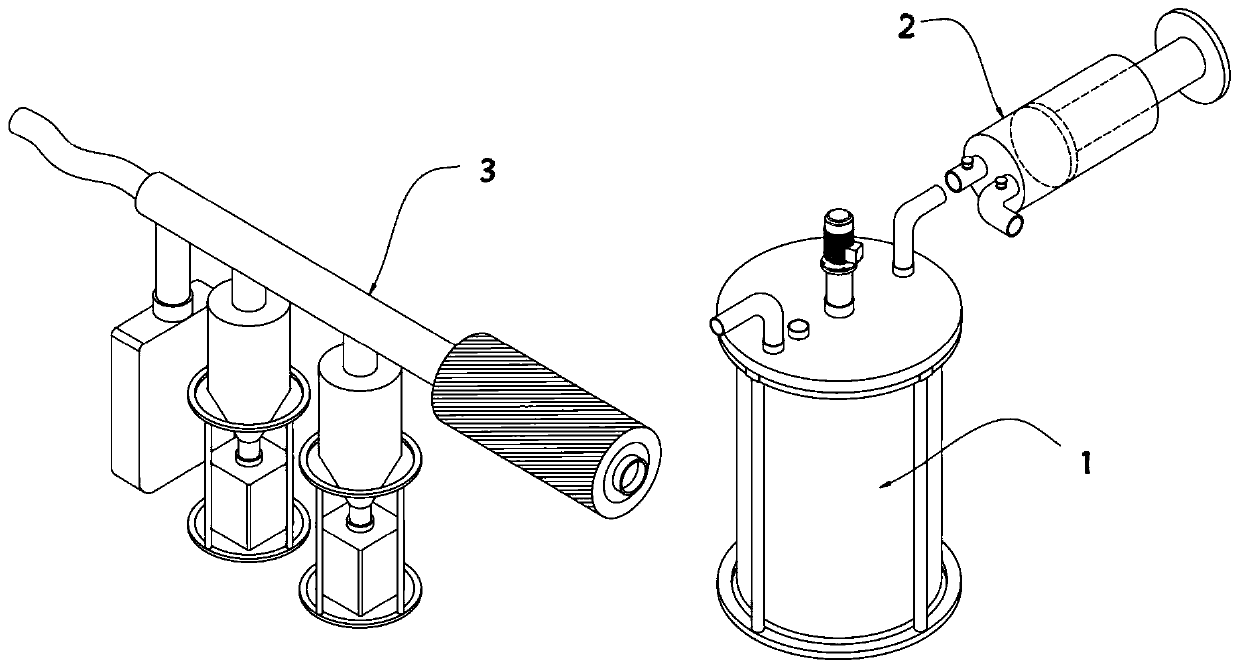

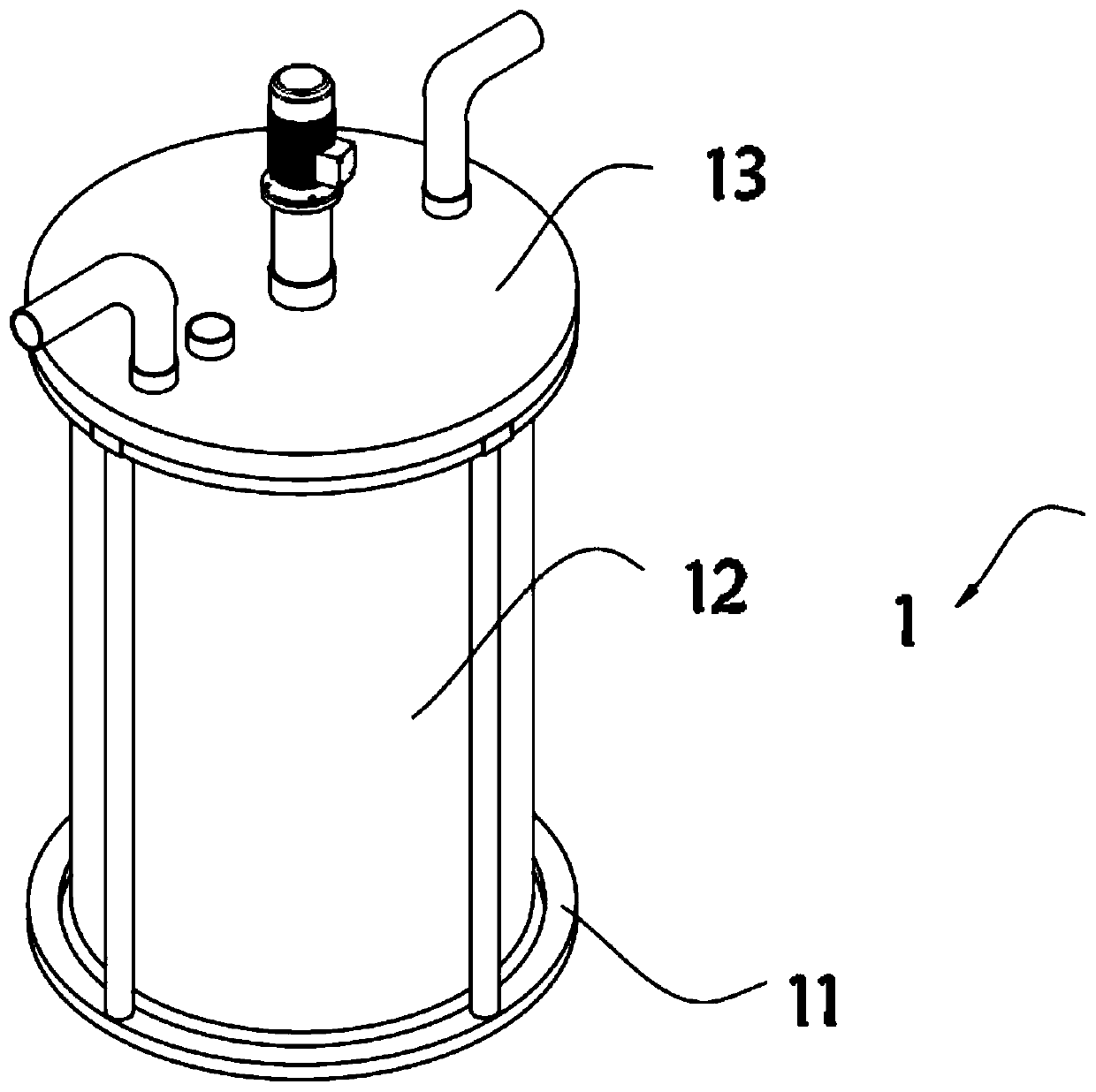

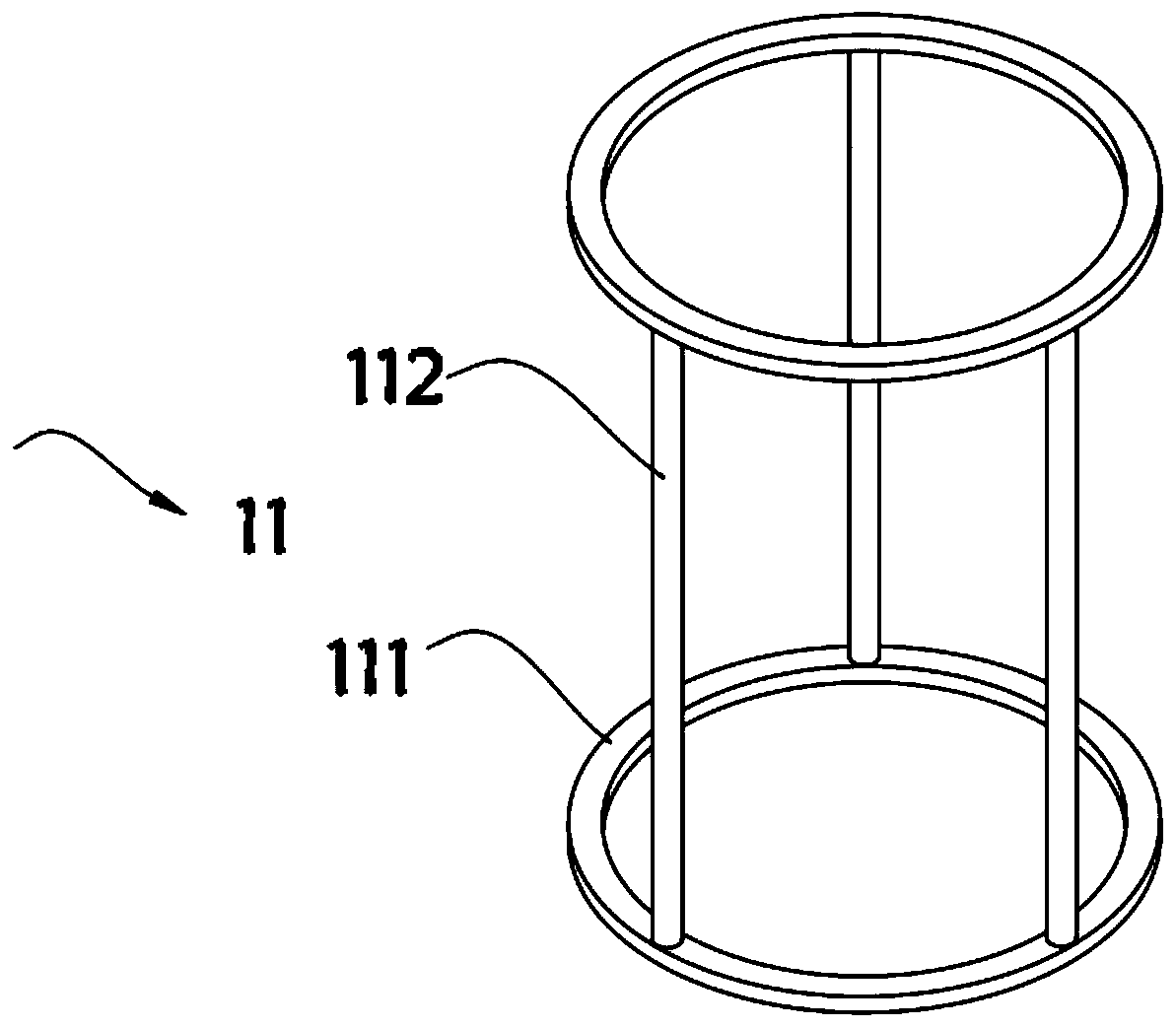

[0044] In one aspect, the present invention provides a device for artificially synthesizing platelets in vitro in a fluid movement mode, such as Figure 1 to Figure 7 As shown, it includes a platelet production device 1, a vacuum suction device 2, and a platelet enrichment device 3. The platelet production device 1 includes a placement frame 11 and a generation cylinder 12 arranged inside the placement frame 11. A snap ring 111, a plurality of connecting posts 112 are installed between the two snap rings 111, a top cover 13 is provided on the top of the generating cylinder 12, a turbulent flow system 14 is arranged inside the generating cylinder 12, and the turbulent flow system 14 includes a spline shaft 141, The bottom of the spline shaft 141 is equipped with an upper blade 142, the bottom of the upper blade 142 is equipped with a telescopic column 143, the bottom of the telescopic column 143 is equipped with a lower blade 144, and the top side of the top cover 13 is equipped...

Embodiment 2

[0052] As the second embodiment of the present invention, in the specific operation process, the turbulent flow system cannot be completely simulated only by the rotating blades. In order to obtain clean platelets, kinetic energy must be generated to force the quasi-platelets to split themselves. 141 to make improvements, as a preferred embodiment, such as Figure 8 to Figure 11 As shown, the upper end of the spline shaft 141 is equipped with an upper mounting plate 1411, the bottom of the upper mounting plate 1411 is provided with a fixed cylinder 1412, the inner top of the fixed cylinder 1412 is equipped with a telescopic cylinder 1413, and the bottom of the telescopic cylinder 1413 is provided with a connecting plate 1414 The top of the connecting plate 1414 is provided with a plurality of mounting screws 1415, the bottom of the connecting plate 1414 is provided with a telescopic shaft 1416, the top of the telescopic shaft 1416 is provided with a plurality of mounting holes ...

Embodiment 3

[0061] As a third embodiment of the present invention, in order to facilitate the vacuum adsorption of the culture solution, the inventors set up a vacuum suction device 2, as a preferred embodiment, such as Figure 12 As shown, the vacuum suction device 2 includes a hollow tube 21, a piston pad 22 is arranged inside the hollow tube 21, a push rod 23 is installed on one end of the piston pad 22, and a push plate 24 is arranged on the other end of the push rod 23. The outer wall of empty pipe 21 is equipped with liquid suction port 25 and liquid discharge port 26 respectively, and the outer wall of liquid suction port 25 and liquid discharge port 26 is all equipped with common valve 27, and liquid suction port 25 and liquid discharge port 26 are all connected with hollow tube. 21 connected.

[0062] In this embodiment, the piston pad 22 is made of rubber material, which has a certain degree of elasticity, and the overall sealing effect is good.

[0063] Further, the size of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com