Full-automatic high-viscosity glue extruding device

A high-viscosity, fully automatic technology, used in devices and coatings that apply liquid to the surface, can solve problems such as slow extrusion speed, potential safety hazards, and rupture of plastic barrels, and achieve fast extrusion speed and good safety. , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

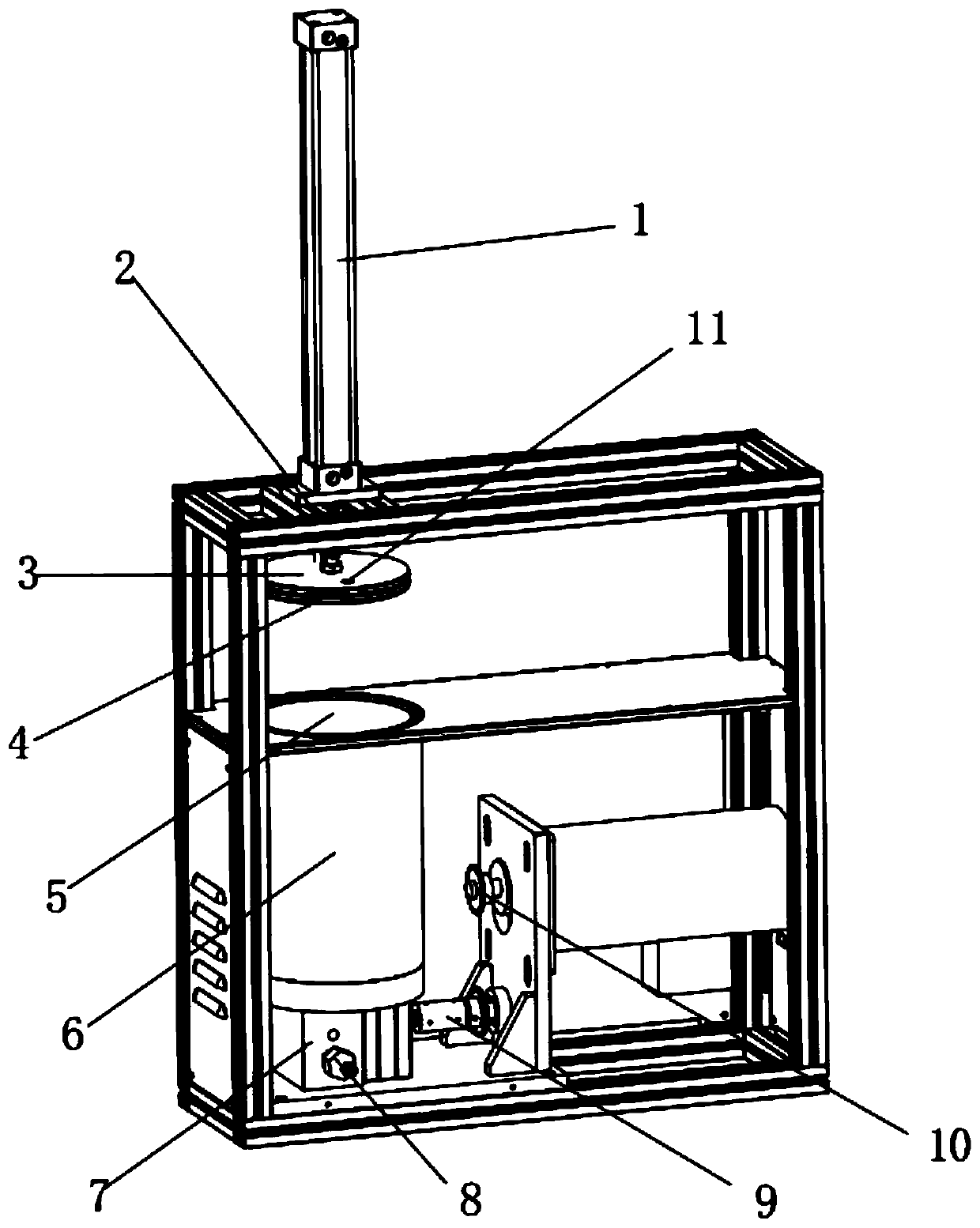

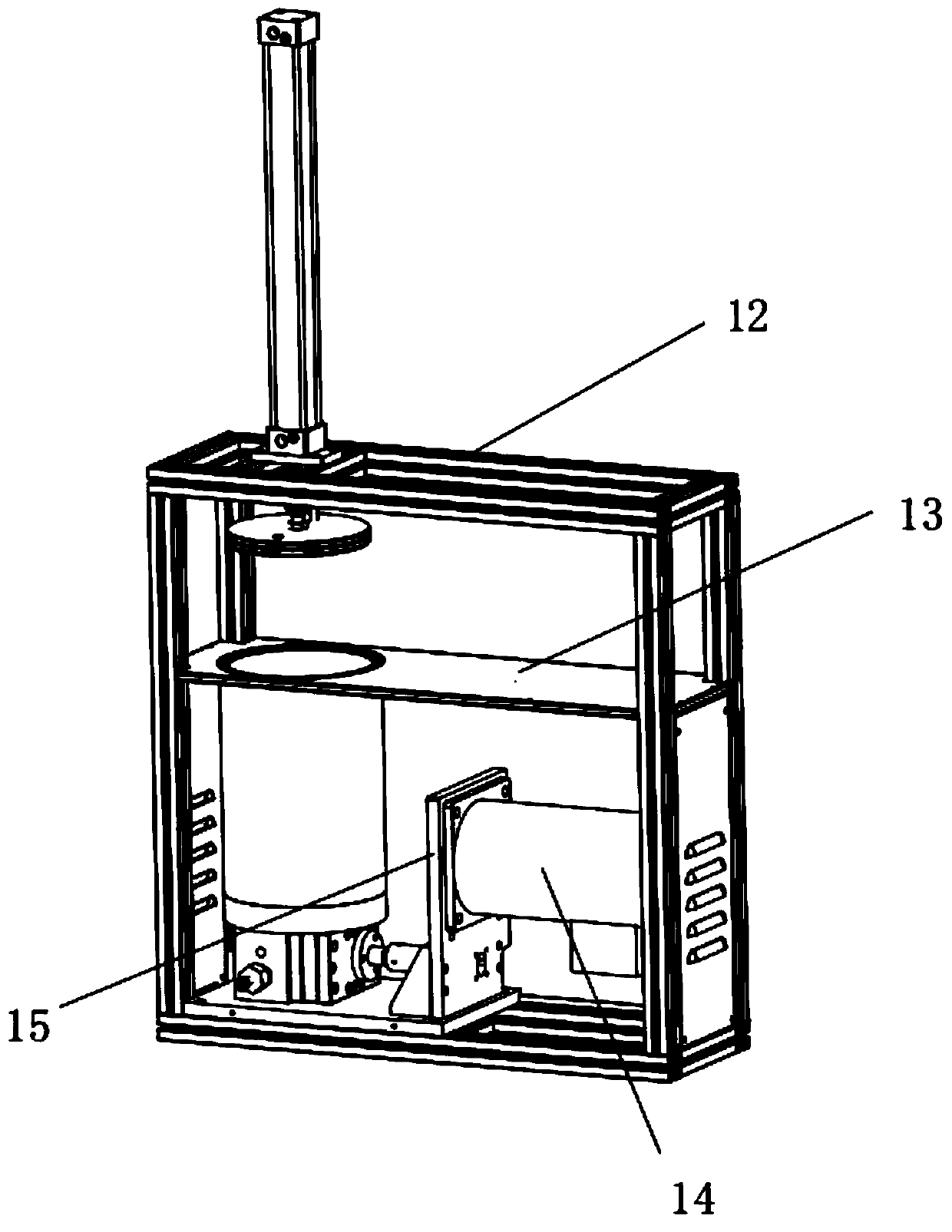

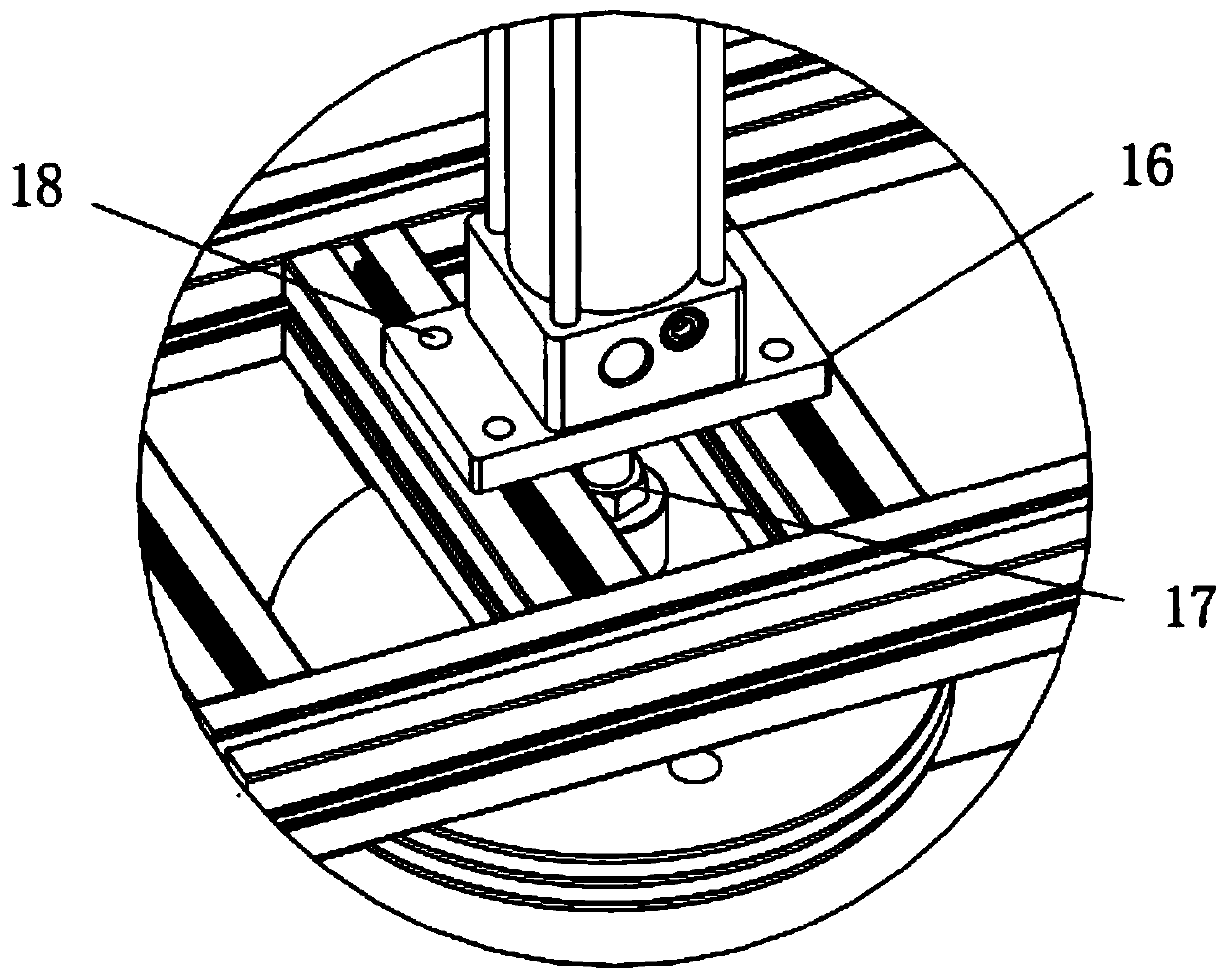

[0016] see Figure 1-3 As shown, the present invention relates to a fully automatic high-viscosity glue squeezing device, which includes a frame 12 and a rubber barrel 6 arranged in the frame 12. The bottom of the glue barrel 6 is provided with a glue leakage hole, and also includes a variable frequency motor 14 , gear pump 7, cylinder 1, cylinder pressure plate 3, frequency conversion motor 14 is connected with the input shaft 9 of the gear pump 7; The glue leakage hole is communicated with the feed port of the gear pump 7; the cylinder 1 is fixedly arranged on the upper end of the frame 12 and is positioned above the rubber bucket 6, and the cylinder pressure plate 3 is fixedly connected with the piston rod 17 of the cylinder 1, The cylinder pressure plate 3 is arranged in the rubber barrel 6 and its side is attached to the inner wall of the rubber barrel 6 , and the surface of the cylinder pressure plate 3 is provided with an exhaust hole 11 .

[0017] As a preferred examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com