CPVC (Chlorinated Polyvinyl Chloride) composite with better impact resistance

A technology of impact resistance and CPVC resin, which is applied in the field of CPVC compositions, can solve the problems of reducing the tensile strength of CPVC materials, difficult processing of CPVC materials, and high price, and achieve market competitiveness, low extrusion pressure, and reduced production price effect

Active Publication Date: 2014-01-15

CHINA PETROLEUM & CHEM CORP

View PDF4 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, since the brittleness of PVC resin increases with the increase of chlorine content after chlorination, impact modification must be carried out when processing CPVC resin.

[0003] At present, the toughening modifiers used in CPVC are mainly acrylonitrile-butadiene-styrene copolymer (ABS) resin, methacrylate-butadiene-styrene copolymer (MBS) resin, chlorinated polystyrene Ethylene (CPE), acrylic polymer (ACR), silicone-acrylic elastomer, a large amount of ABS, MBS, CPE, ACR modifiers can improve the toughness of CPVC materials, making CPVC materials more difficult to process, and It greatly reduces the tensile strength of CPVC materials, while silicone-acrylic elastomers are not produced in China and are expensive

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

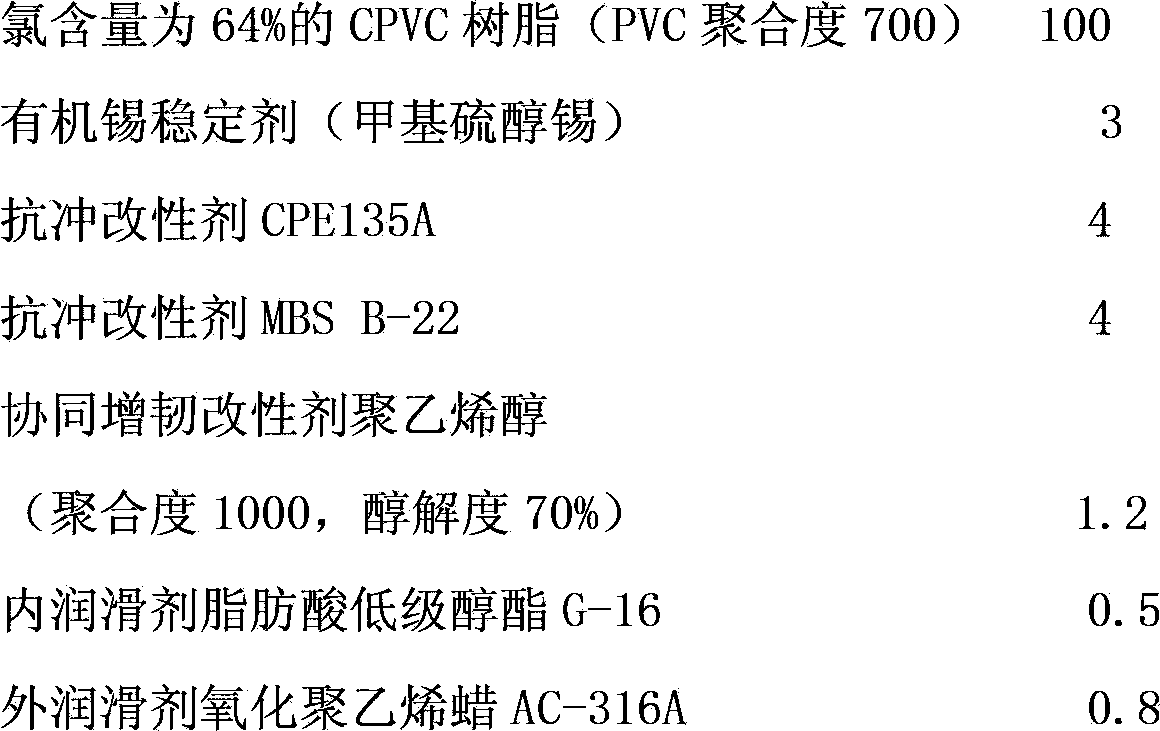

Embodiment 1

[0027]

[0028]

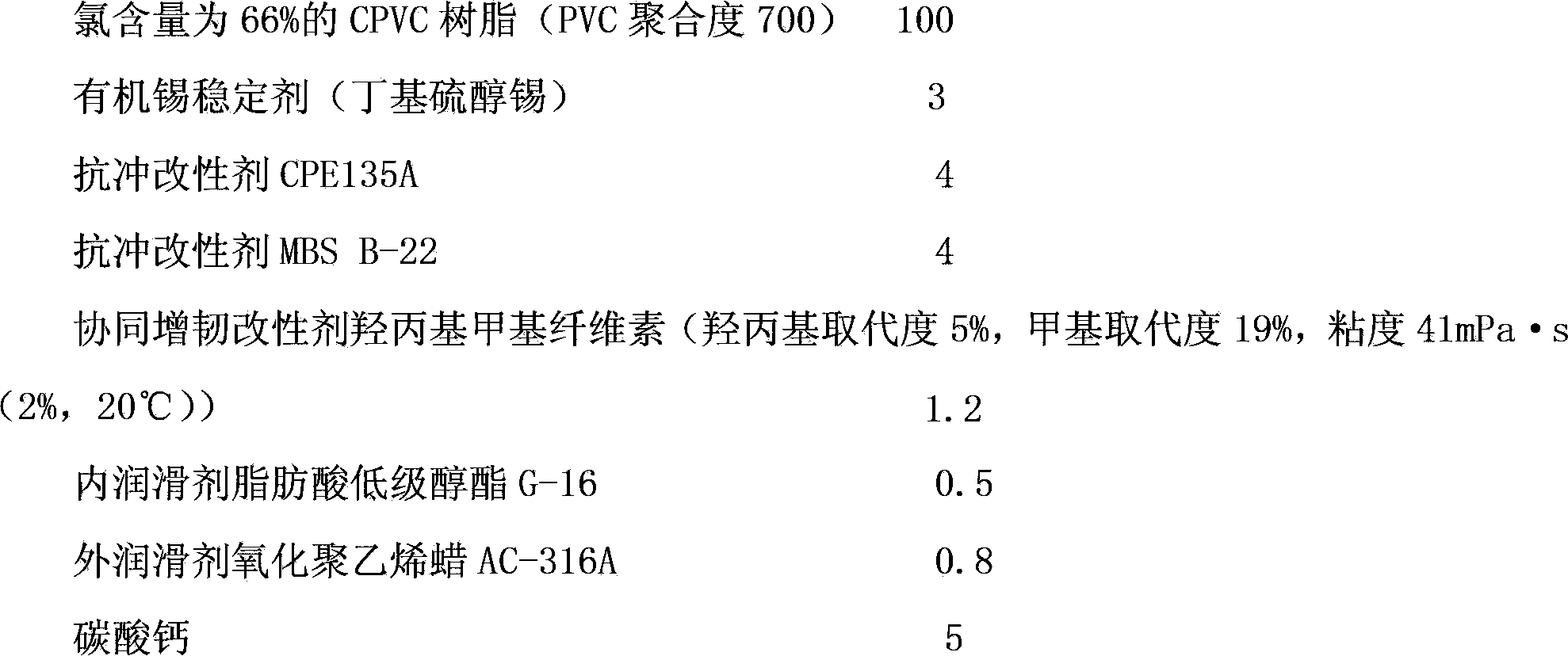

Embodiment 2

[0030]

Embodiment 3

[0032]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a CPVC composite with better impact resistance, and belongs to the field of high molecular materials. The CPVC composite is characterized by being prepared from the following raw materials in parts by mass: 100 parts of CPVC resin, 3-8 parts of stabilizer, 1.2-3.2 parts of complex lubricating agent, 6-10 parts of complex toughened modifier, 0.5-2.0 parts of synergistic toughened modifier and 3-10 parts of filler. According to the invention, a complex impact resistant modifier and a synergistic toughened modifier are used for performing impact resistant modification on the CPVC composite, so that the impact resistance of the CPVC material is improved greatly, and the CPVC composite has higher tensile strength and better processability; meanwhile, production price of products is lowered, so that the product has higher market competitiveness.

Description

technical field [0001] The invention relates to a CPVC composition with good impact resistance, which belongs to the field of polymer materials. Background technique [0002] Chlorinated polyvinyl chloride resin (CPVC) is obtained by chlorination and modification of polyvinyl chloride resin (PVC), and its chlorine content is generally 61%-73%. Therefore, in terms of physical and mechanical properties, heat resistance, weather resistance, corrosion resistance, flame retardant and self-extinguishing properties, it has been greatly improved compared with PVC, and it is a material with excellent performance. It is widely used in the manufacture of various pipes, plates, profiles, sheets, injection molded parts, foam materials, anti-corrosion coatings, etc., and has a large market prospect. However, since the brittleness of PVC resin increases with the increase of chlorine content after chlorination, impact modification must be carried out during processing of CPVC resin. [00...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L27/24C08L1/26C08L29/04C08L23/28C08L51/00C08K5/58C08K3/22C08K3/34C08K3/26

Inventor 李长春张学明贾小波孔秀丽许永森

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com