Thermoplastic low-smoke halogen-free flame-retardant polyolefin special material for optical cable micro-beam tube and preparation method of special material

A thermoplastic and polyolefin technology, which is applied in the field of thermoplastic low-smoke, halogen-free, flame-retardant polyolefin special materials for optical cable micro-bundle tubes and its preparation, low-smoke, halogen-free, flame-retardant polyolefin plastics, can solve the problem of burning and releasing toxic gases, polyolefin materials No flame retardant, poor stability and other problems, to achieve the effect of low smoke toxicity, fast extrusion speed, and not easy to ignite and spread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

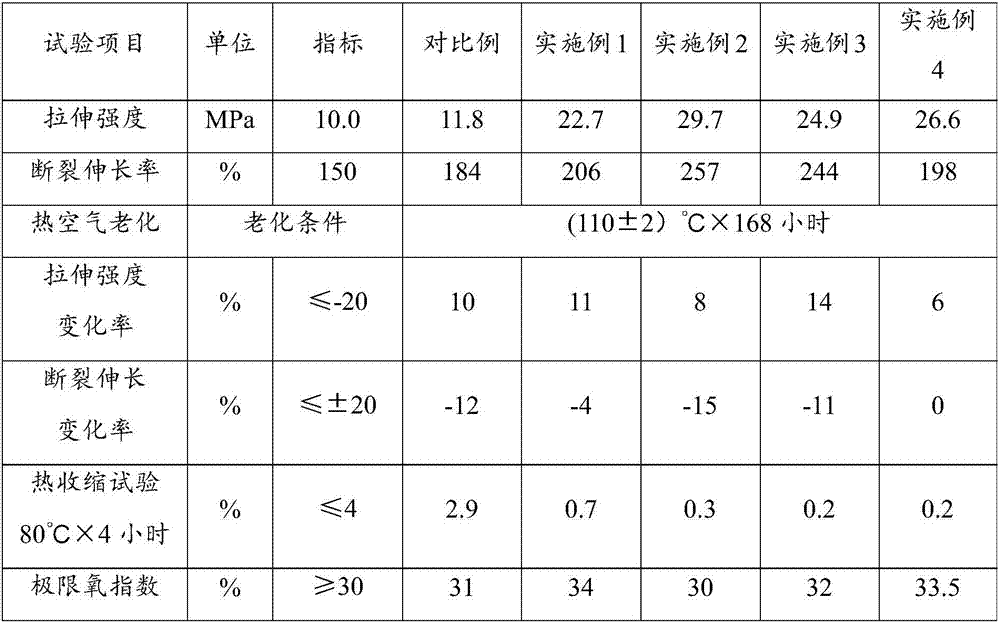

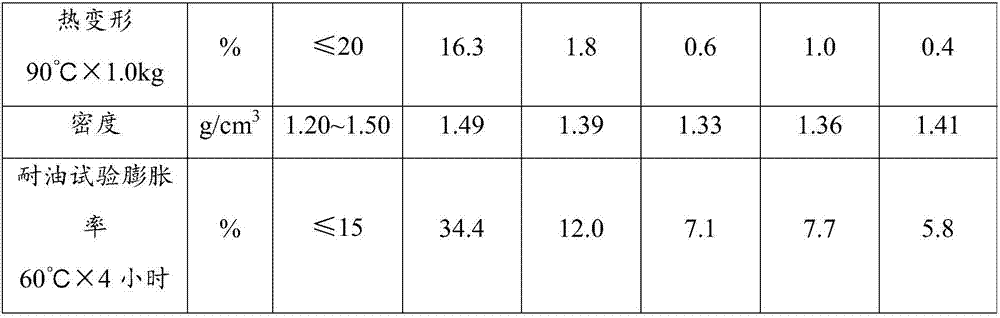

Examples

Embodiment 1

[0039]A thermoplastic low-smoke halogen-free flame-retardant polyolefin special material for optical cable micro-bundle tubes, comprising 10 parts of polypropylene, 45 parts of high-density polyethylene, 5 parts of EPDM rubber, and 25 parts of ultra-low-density polyethylene 15 parts of compatibilizer, 1 part of high molecular weight polysiloxane, 0.1 part of plasticizer, 0.1 part of surface slippery agent, 120 parts of high-efficiency composite flame retardant, 2.5 parts of tubular microcrystalline nano-char forming agent, organosilane 2 parts, 2 parts of antioxidant, 3 parts of processing aid.

[0040] The polypropylene is a copolymerized polypropylene, containing 1% of ethylene monomer and 99% of propylene monomer in terms of mole fraction, its melt index is 5g / (10min, 2.16kg), and its density is 0.86g / cm 3 .

[0041] The melt index of the high-density polyethylene is 0.5g / (10min, 2.16kg).

[0042] The EPDM rubber is a copolymer composed of 70% ethylene, 25% propylene and ...

Embodiment 2

[0057] A thermoplastic low-smoke halogen-free flame-retardant polyolefin special material for optical cable micro-bundle tubes, including 25 parts of polypropylene, 20 parts of high-density polyethylene, 15 parts of EPDM rubber, and 25 parts of ultra-low density polyethylene 15 parts, compatibilizer, 2.5 parts of high molecular weight polysiloxane, 2.5 parts of plasticizer, 2 parts of surface slippery agent, 80 parts of high-efficiency composite flame retardant, 0.5 parts of tubular microcrystalline nano-char forming agent, organosilane 1 part, 0.5 part of antioxidant, 1 part of processing aid.

[0058] The polypropylene is a co-polypropylene, containing 7% of ethylene monomer and 93% of propylene monomer in terms of mole fraction, its melt index is 15.0g / (10min, 2.16kg), and its density is 0.90g / cm 3 .

[0059] The melt index of the high-density polyethylene is 1.0 g / (10 min, 2.16 kg).

[0060] The EPDM rubber is a copolymer composed of 75% ethylene, 20% propylene and 5% et...

Embodiment 3

[0076] A thermoplastic low-smoke halogen-free flame-retardant polyolefin special material for optical cable micro-bundle tubes, including 20 parts of polypropylene, 45 parts of high-density polyethylene, 10 parts of EPDM rubber, and 15 parts of ultra-low density polyethylene 10 parts, 10 parts of compatibilizer, 5 parts of high molecular weight polysiloxane, 2 parts of plasticizer, 2 parts of surface slippery agent, 100 parts of high-efficiency composite flame retardant, 2 parts of tubular microcrystalline nano-char forming agent, organosilane 2 parts, 1.5 parts of antioxidant, 2 parts of processing aid.

[0077] The polypropylene is a copolymerized polypropylene, containing 3% of ethylene monomer and 97% of propylene monomer in terms of mole fraction, its melt index is 5.0g / (10min, 2.16kg), and its density is 0.88g / cm 3 .

[0078] The melt index of the high-density polyethylene is 1.0 g / (10 min, 2.16 kg).

[0079] The EPDM rubber is a copolymer composed of 70% ethylene, 25%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com