Submerged arc automatic welding process for high-strength steel Q460GJD for building structure

An automatic submerged arc welding technology for steel used in building structures, applied in welding equipment, welding media, welding equipment, etc., can solve problems such as unstable quality, easy cracks, and low quality grades, and achieve high quality grades and improved productivity , the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

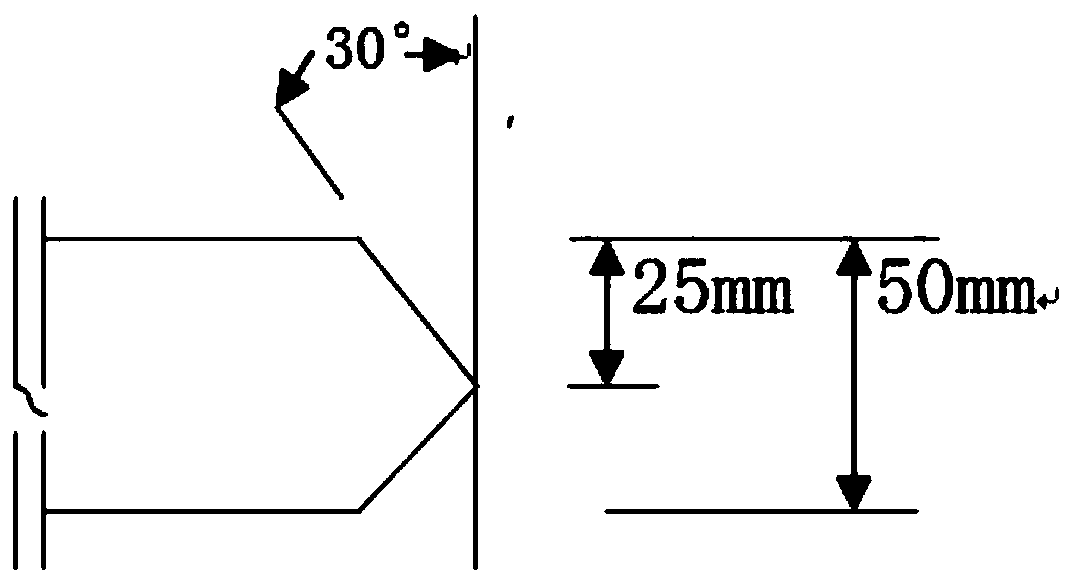

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0037] The chemical composition of Q460GJD steel plate (base material) with a thickness of 50mm meets the range C: 0.10~0.17%, Si: 0.20~0.50%, Mn: 1.2~1.60%, P: ≤0.012%, S: ≤0.007%, Cr: 0.01 ~0.50%, Mo: ≤0.30%, Ni: 0.10~0.30%, Cu: ≤0.30%, Al: 0.02~0.04%, V+Nb+Ti: 0.07~0.15%, N: ≤0.004%, the balance is Fe and unavoidable impurity elements; wherein, carbon equivalent%=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15), carbon equivalent≤0.50%, the mother of this embodiment See Table 1 for material composition. See Table 2 for mechanical properties.

[0038] Welding process: The preheating temperature of the motherboard before welding is 120°C, and the multi-layer and multi-pass welding process is adopted, and the interlayer temperature is 160°C. Other welding parameters are shown in Table 3. Strictly bake the flux before use, the baking temperature is 350°C, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com