Novel multi-functional assembly device

An assembly device and multi-functional technology, applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of complex processing, slow production speed, low work efficiency, etc., to simplify the work process and reduce work Difficulty, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

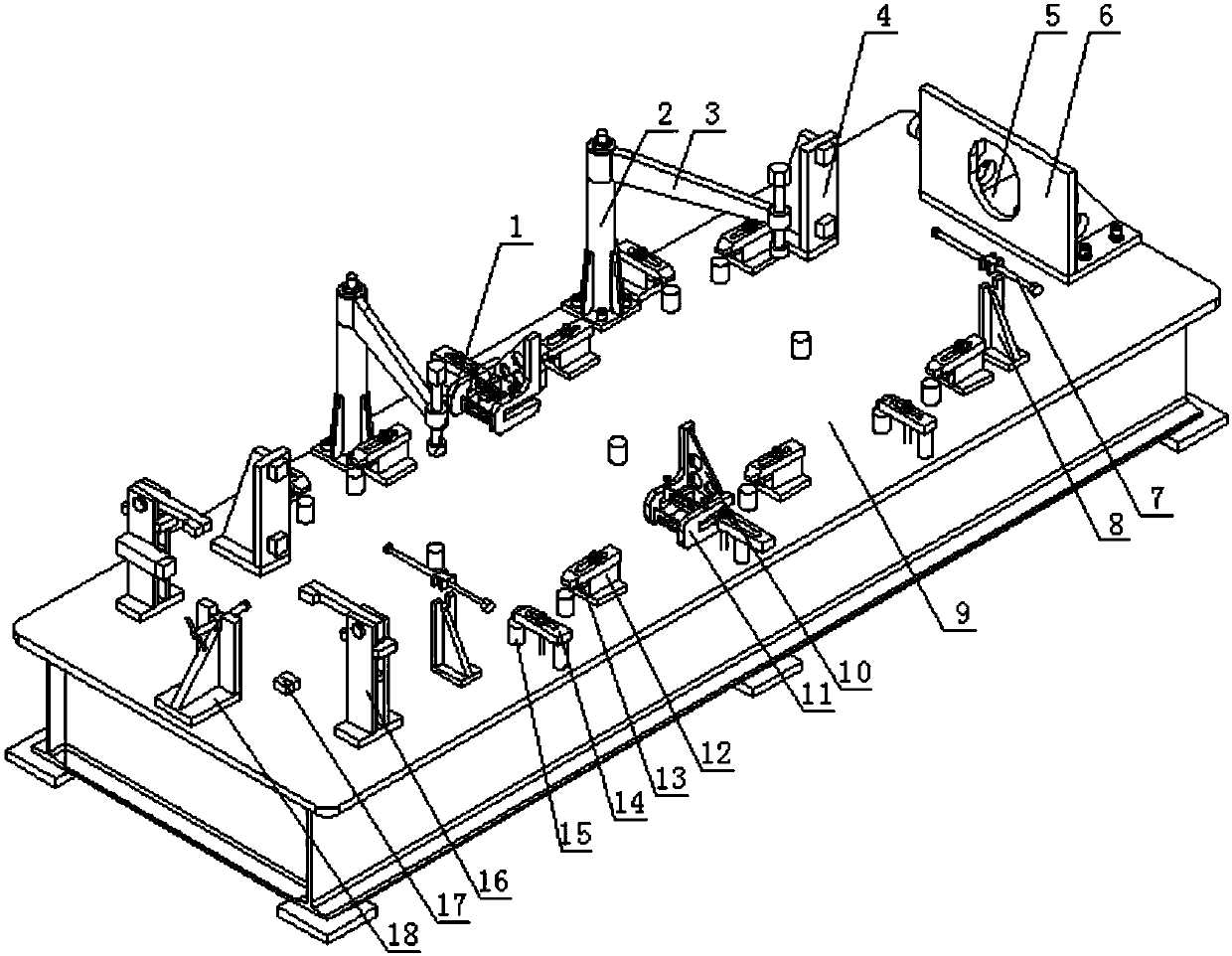

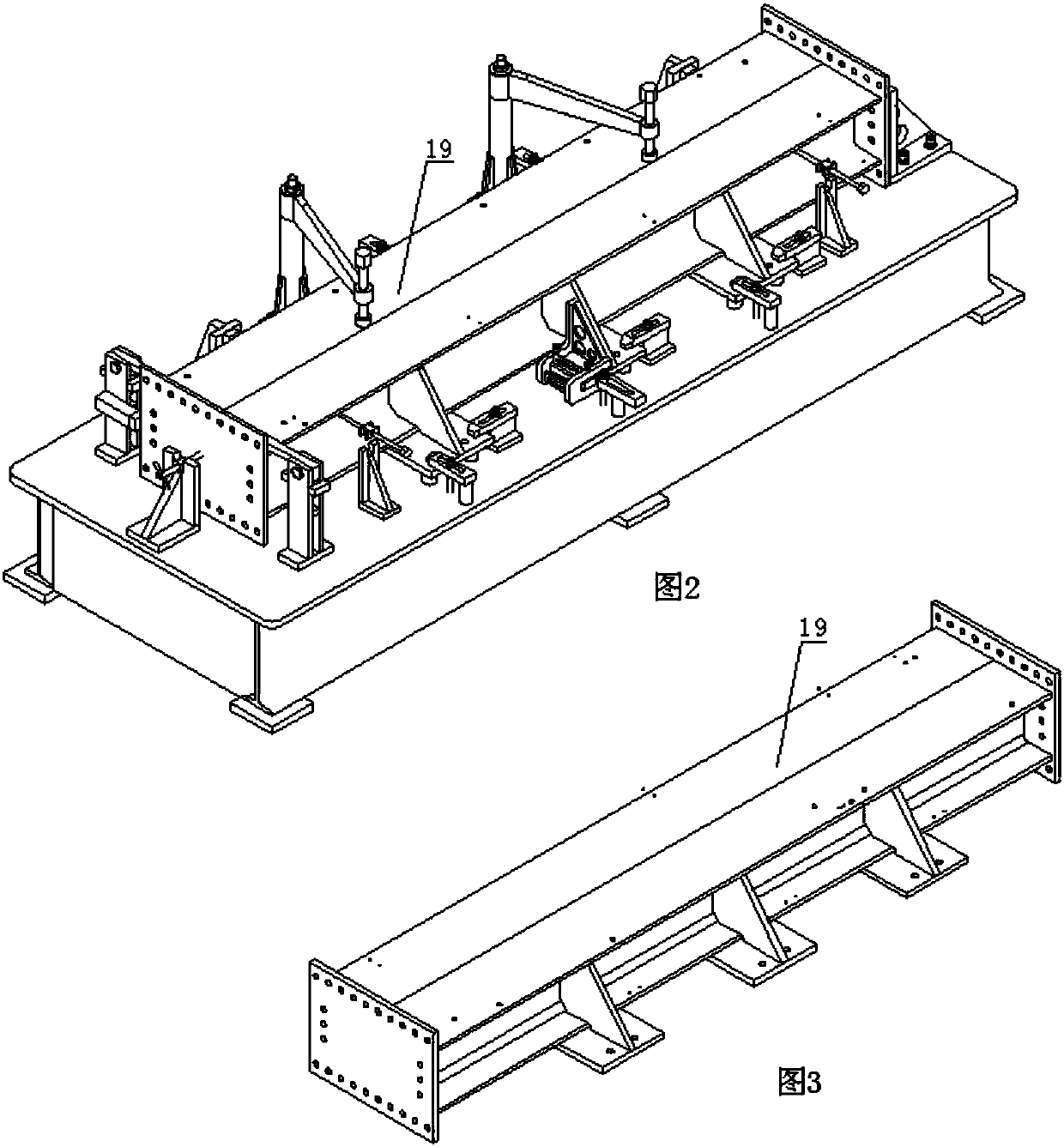

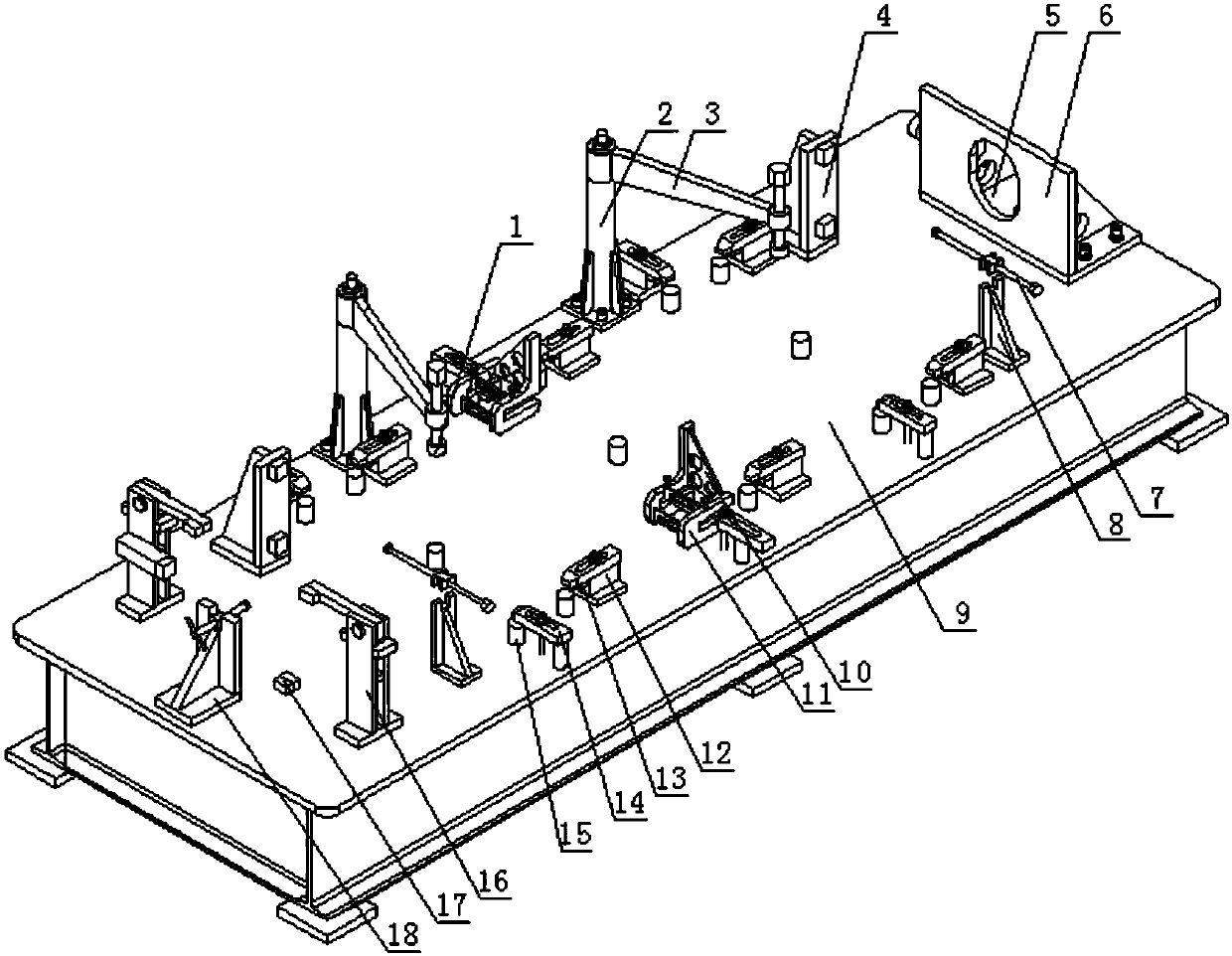

[0024] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

[0025] A new type of multifunctional assembly device, including a tooling base 9, a bottom plate positioning and fixing device, an H beam positioning and fixing device, a side plate positioning and fixing device, and a rib plate positioning and fixing device, the bottom plate positioning and fixing device, the H beam positioning and fixing device, the side plate Both the positioning and fixing device and the rib plate positioning and fixing device are installed on the upper surface of the frock base. The structure of each part is described in detail below:

[0026] ⑴. The bottom plate positioning and fixing device includes a bottom bracket 15, a positioning column 13 and a long pressure plate. Three bottom plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com