Double-head impact screwdriver device

A screwdriver and impact head technology, which is applied in the field of double-head impact screwdriver devices, can solve the problems of tilting, jamming, and untorqued bolts and nuts of the insulating casing of the insulation piercing clip, so as to achieve adaptability and practicability. Good, the twisting and breaking process is smooth, and it is easy to adjust the effect of the operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

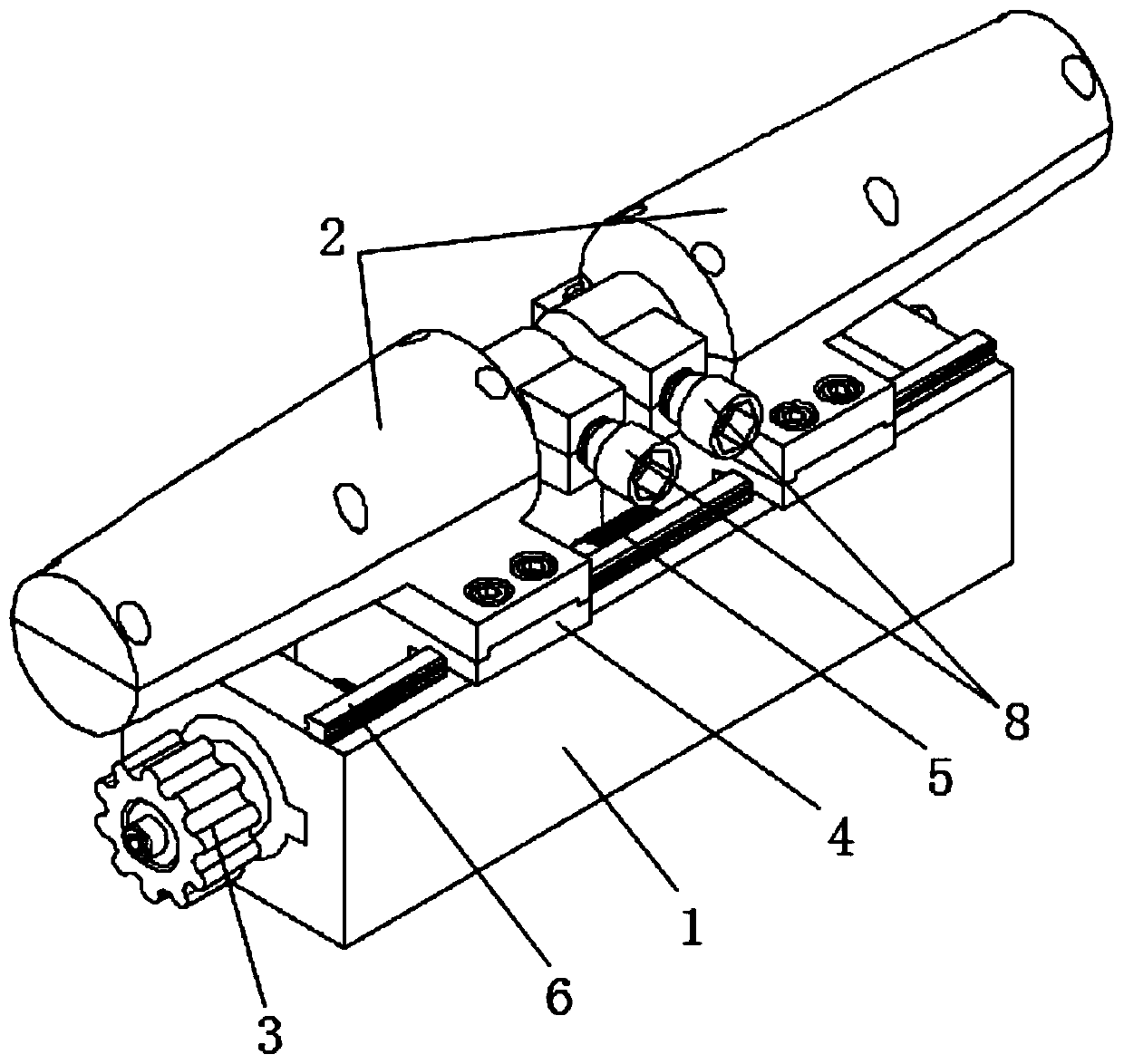

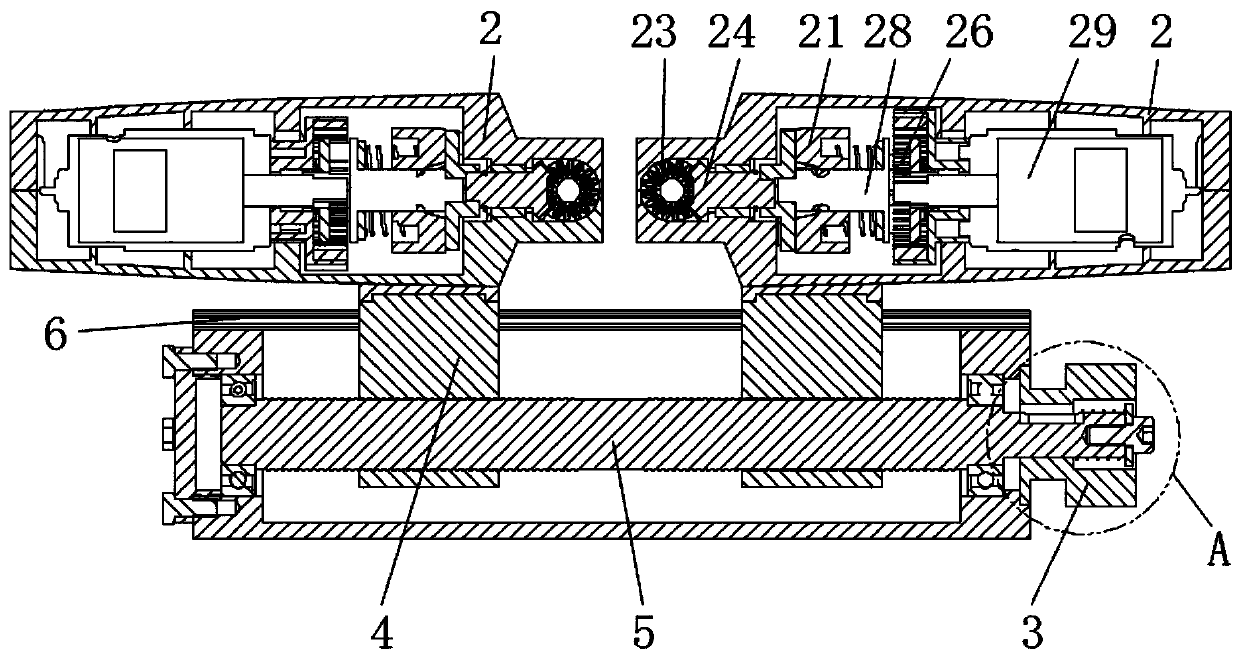

[0036] see figure 1 and figure 2 , a double-head impact screwdriver device, including a base 1, two impact wrenches 2, a slide 4, a lead screw 5, and an adjustment device 3. The lead screw 5 is rotatably connected in the base 1, and two slide plates 4 are threaded on the lead screw 5, and an impact wrench 2 is installed on the top of each slide plate 4, and the power output ends of the two impact wrench 2 are located on the same side of the base 1 , and are fixedly connected with the sleeve 8. The sleeve 8 is used to connect the impact wrench 2 to the bolt to be tightened, and the shape of its inner hole is determined according to the shape of the head of the torque bolt it acts on.

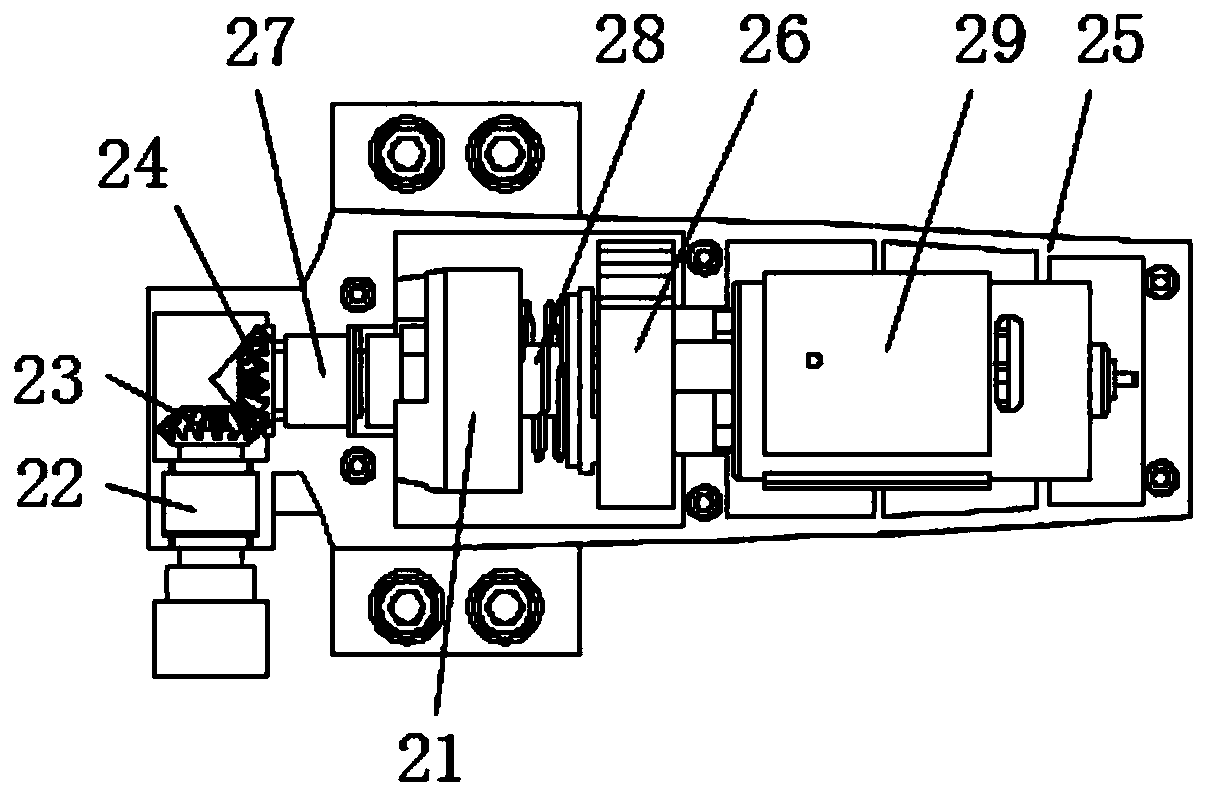

[0037] Such as image 3 As shown, the impact wrench 2 includes a housing 25, an impact motor 29 installed in the housing 25, a reducer 26, an impact head 21, a driven bevel gear 23 and a driving bevel gear 24 respectively rotatably connected in the housing 25. The impact head 21 adopts the s...

Embodiment 2

[0044] see Figure 6 The difference between this embodiment and Embodiment 1 is that: only one end of the lead screw 5 is provided with a threaded section, and a slide plate 4 is threadedly connected to the threaded section, and the top surface of the base 1 is fixedly installed with a slide plate 4- The fixed plate 9 on the side, the top of the sliding plate 4 and the fixed plate 9 are respectively equipped with an impact wrench 2 . The power output ends of the two impact wrenches 2 are located on the same side of the base 1 , and both are fixedly connected with a sleeve 8 . Other features are the same as in Embodiment 1.

[0045] In this embodiment, the adjusting device 3 drives the lead screw 5 to rotate, and under the action of screw transmission, the slide plate 4 on the lead screw 5 and the impact wrench 2 on the top of the slide plate 4 move horizontally, approaching or away from the impact on the fixed plate 9 Wrench 2, so as to realize the distance adjustment betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com