Carbon fiber forming mold and method

A forming mold and carbon fiber technology, applied in the field of carbon fiber forming molds, can solve the problems of high molding cost and inability to form spatial forms, and achieve the effects of low cost, ingenious design, and easy demoulding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

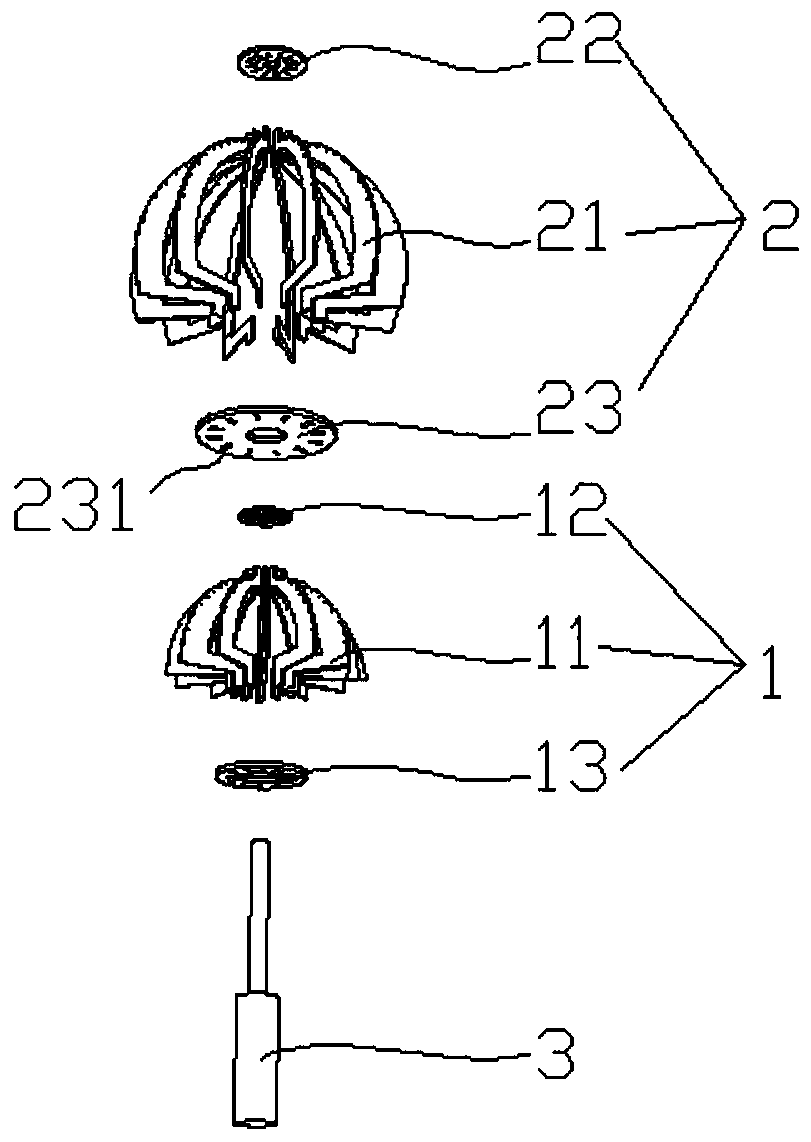

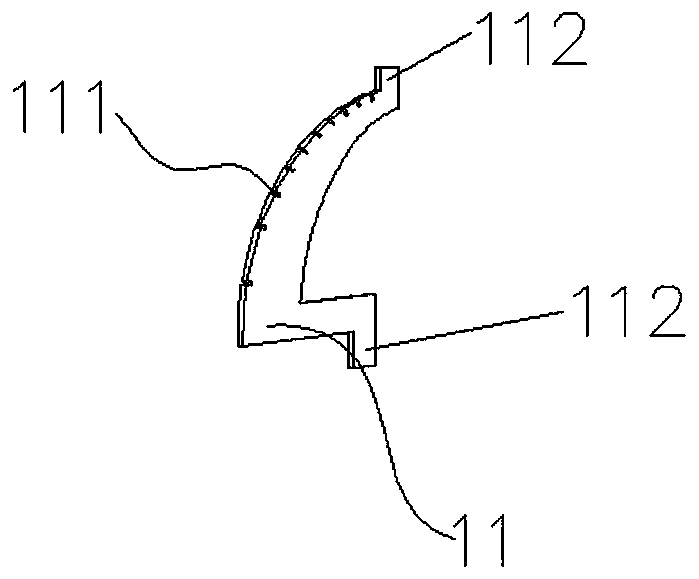

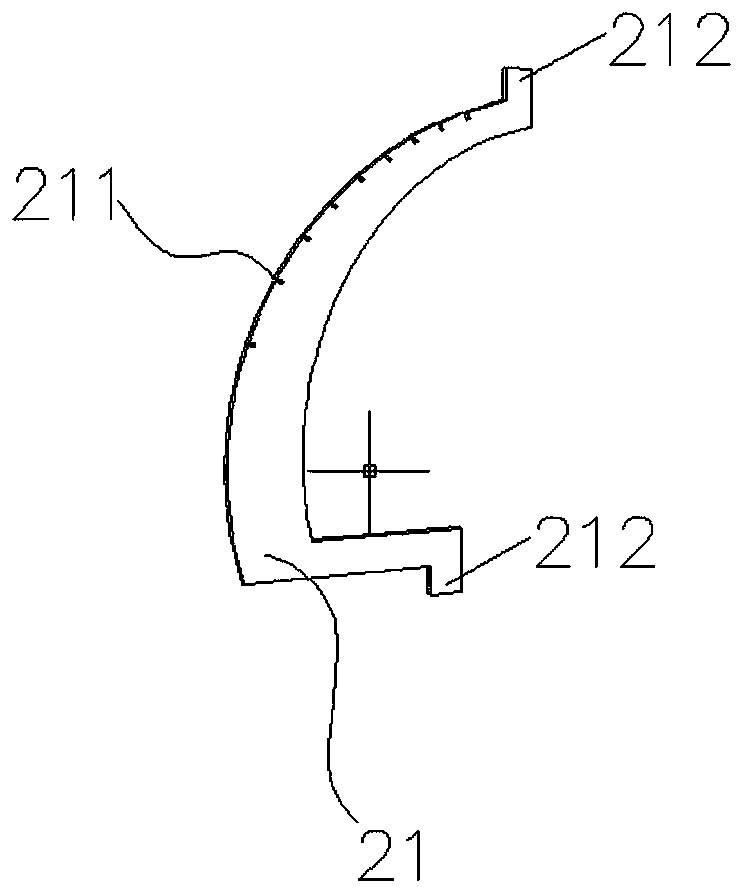

[0038] Examples, see Figure 1-Figure 10 As shown, a carbon fiber molding die according to the present invention includes a mold frame for winding a carbon fiber substrate with a resin-coated surface or a resin-mixed surface. The number of the mold frames is specifically two, but not limited thereto. The two mold bases are arranged coaxially, and are in an internal and external distribution relationship. Hereinafter, for the convenience of description, the two formworks are named as inner formwork 1 and outer formwork 2 respectively. Each mold frame respectively includes a plurality of mold pieces and a fixing piece, and a plurality of membrane pieces are distributed at intervals along the circumferential direction of the fixing piece, and each mold piece is detachably connected with the fixing piece respectively. The present invention also includes a central fixed shaft 3 on which the fixing pieces of each formwork are respectively sleeved.

[0039] In this embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com