Steer-by-wire system

A technology of steer-by-wire and steering devices, applied to steering mechanisms, steering rods, mechanical steering mechanisms, etc., can solve problems such as inability to generate reaction force torque, and achieve the effect of ensuring operability and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Embodiments of the present invention will be described with reference to the drawings.

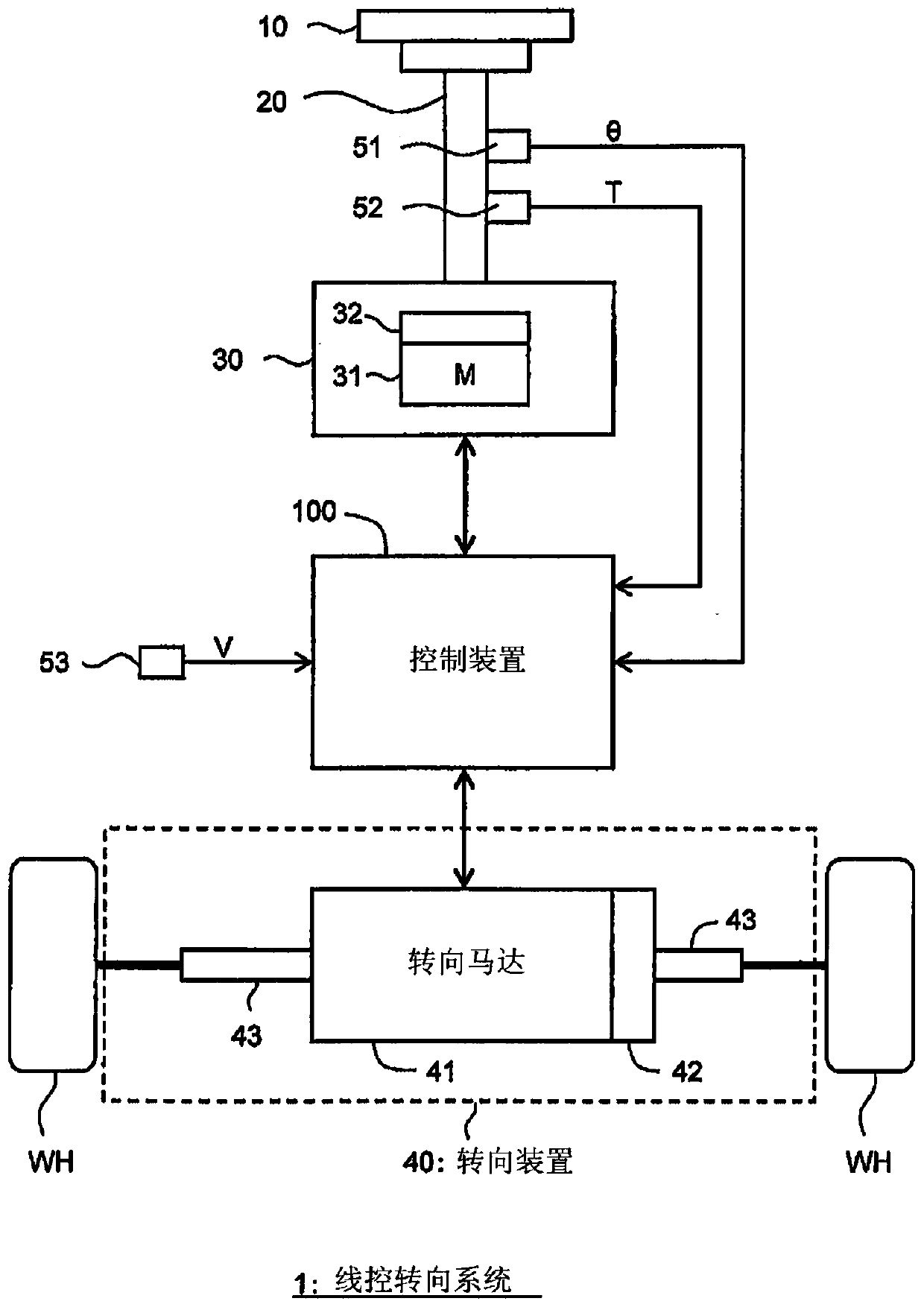

[0067] 1. Basic composition of steering-by-wire system

[0068] figure 1 It is a block diagram schematically showing a configuration example of the steer-by-wire system 1 according to the present embodiment. The steer-by-wire system 1 is mounted on a vehicle, and steers wheels WH of the vehicle by a steer-by-wire system. More specifically, the steer-by-wire system 1 includes a steering wheel 10 , a steering shaft 20 , a steering reaction force generating device 30 , a steering device 40 , a group of sensors ( 51 to 53 ), and a control device 100 .

[0069] A steering wheel 10 (steering wheel) is an operating member used by a driver for steering. The steering shaft 20 is connected to the steering wheel 10 and rotates together with the steering wheel 10 .

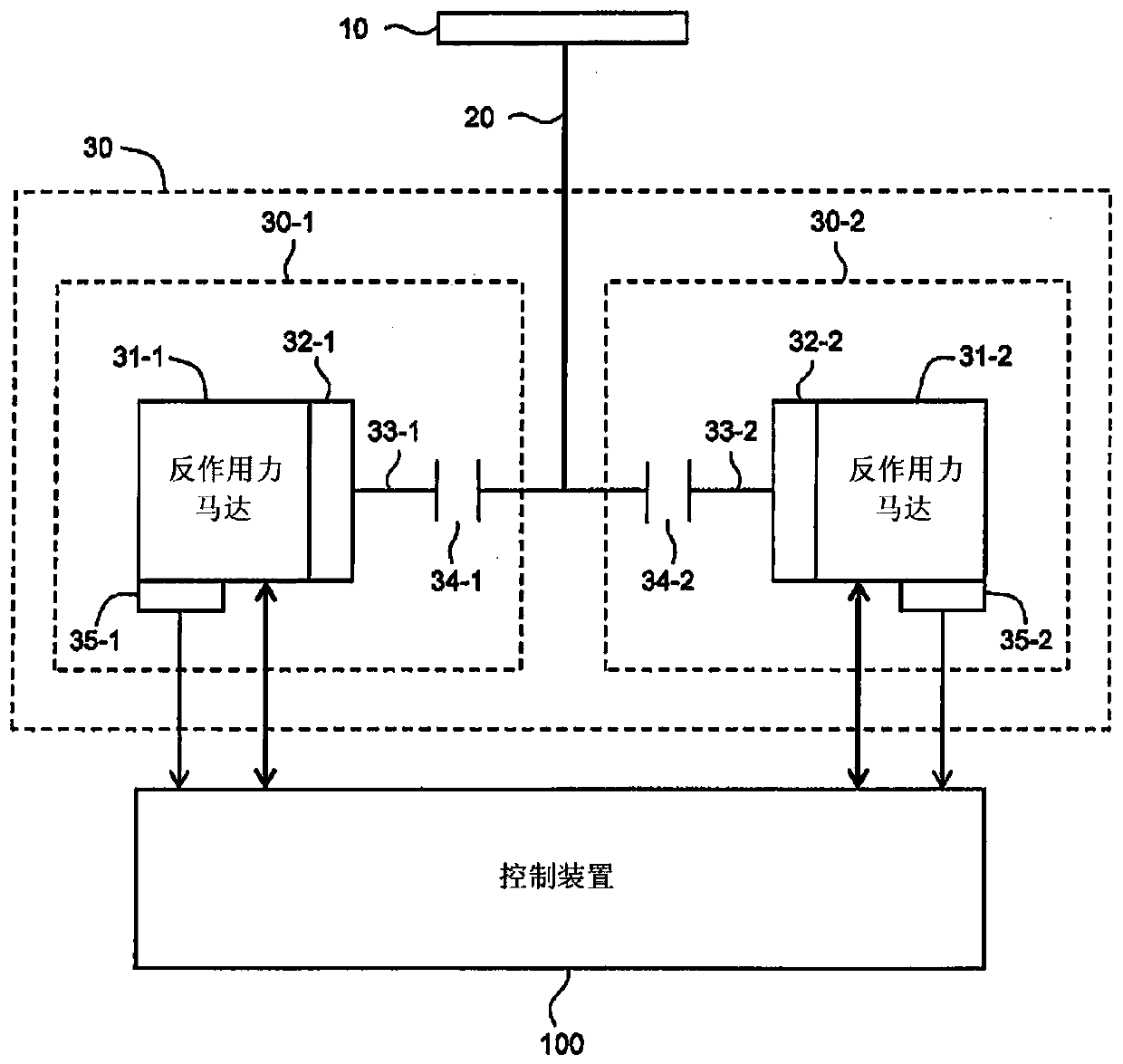

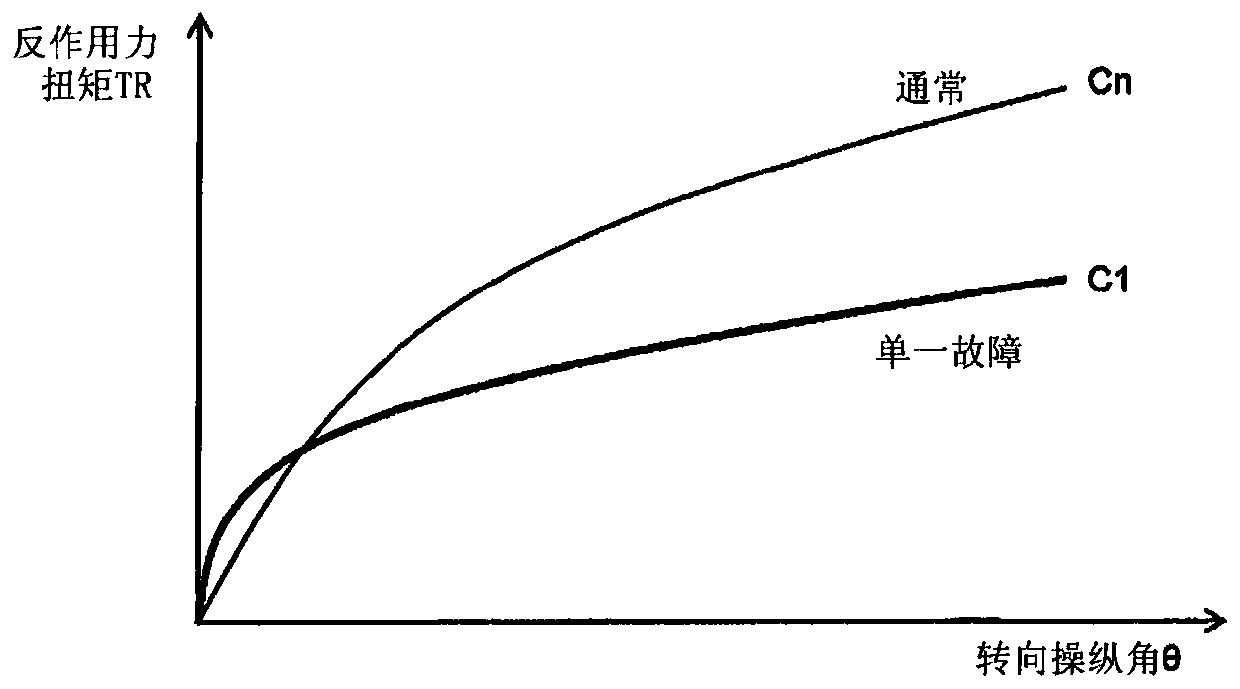

[0070] The steering reaction force generating device 30 simulates a reaction torque TR to the steering wheel 10 . Specifical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com