Military camouflage rubber base material and preparation method thereof

A rubber and camouflage technology, applied in the rubber field, can solve the problems of influence, bad, and cannot contain polar compounding agents, and achieve the effect of good wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

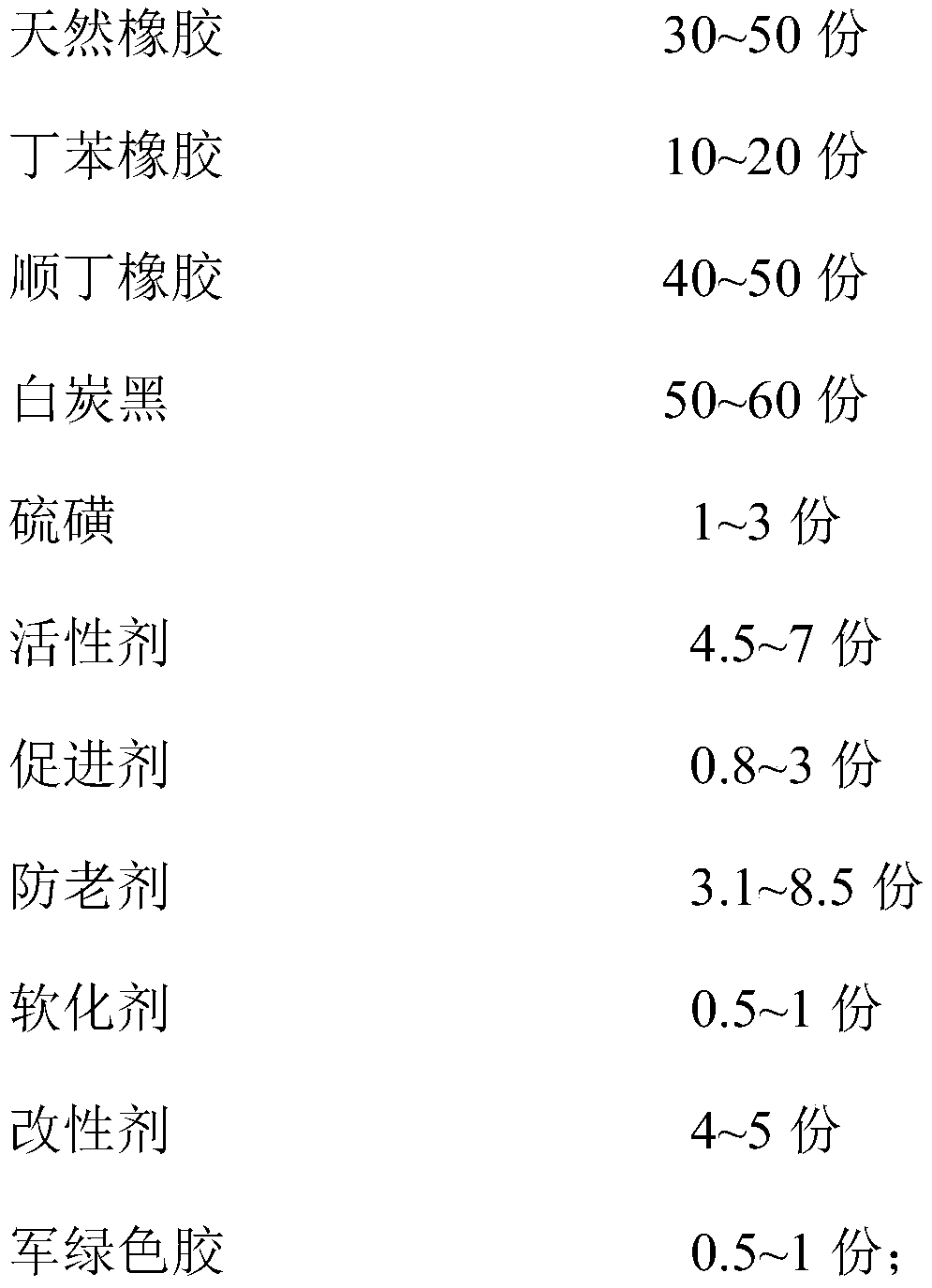

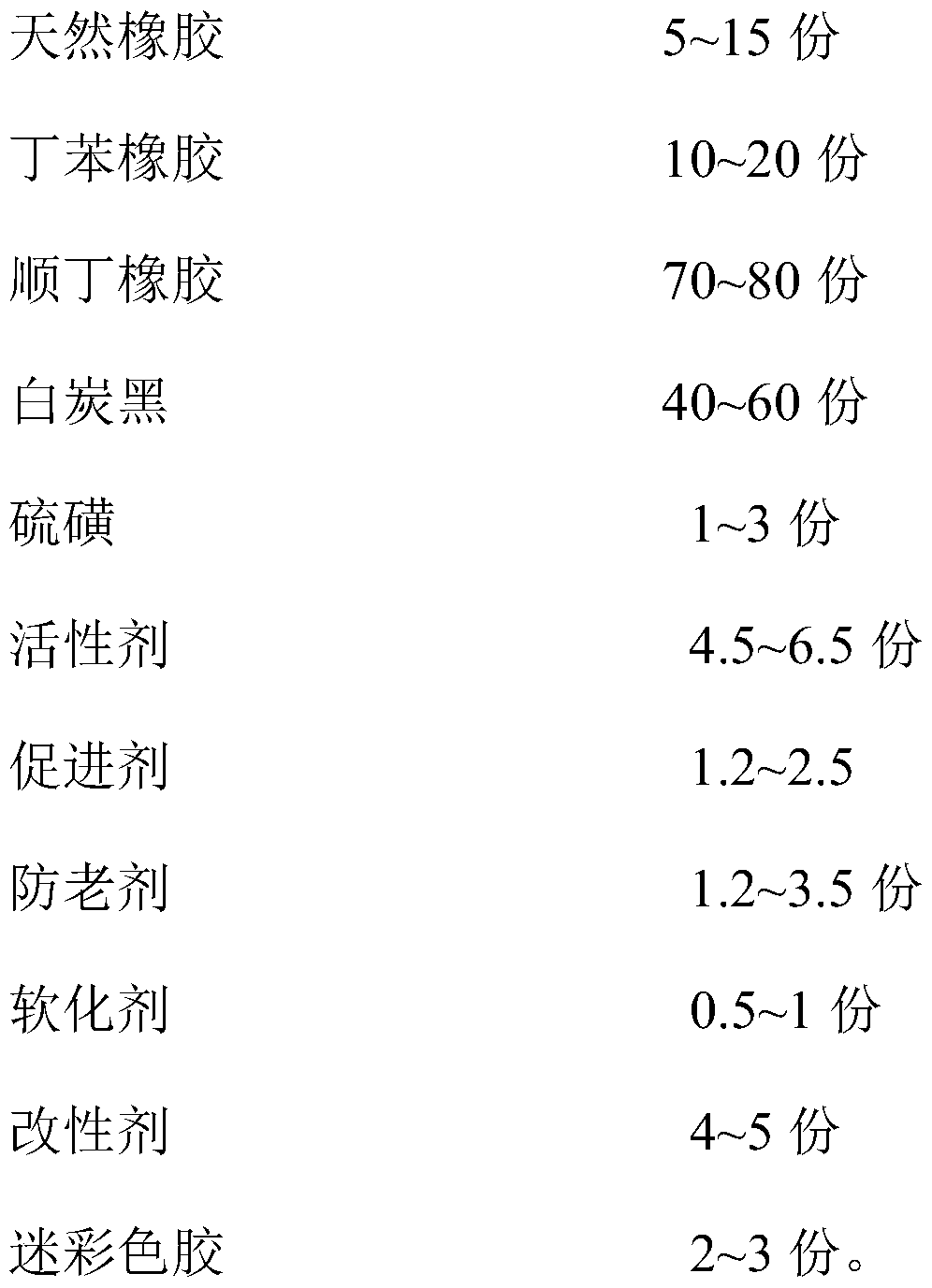

Method used

Image

Examples

Embodiment 1

[0070] The preparation method of the military camouflage rubber substrate of the present embodiment, described preparation method comprises the following steps:

[0071]1) Mix 30 parts of natural rubber, 15 parts of styrene-butadiene rubber and 45 parts of butadiene rubber according to the ratio, and masticate for 2 minutes, add 50 parts of white carbon black, 4.5 parts of active agent, 2 parts of accelerator, 5.9 parts of anti-aging agent, 0.5 1 part of softening agent, 4.3 parts of modifying agent and 0.6 part of army green glue were mixed for 5 minutes at 100°C, and then sulfur was added to vulcanize at 100°C for 0.8h to obtain the main rubber material; wherein, the activator consisted of 4 parts of zinc oxide and 0.5 part of Composed of stearic acid; accelerator consists of 1 part of accelerator DM, 0.5 part of accelerator TS, 0.3 part of accelerator ZDTP and 0.2 part of accelerator D; anti-aging agent consists of 0.5 part of anti-aging agent MB, 0.8 part of anti-aging agen...

Embodiment 2

[0075] The preparation method of the military camouflage rubber substrate of the present embodiment, described preparation method comprises the following steps:

[0076] 1) Mix 40 parts of natural rubber, 10 parts of styrene-butadiene rubber and 50 parts of butadiene rubber according to the proportioning ratio and masticate for 2 minutes, add 55 parts of white carbon black, 6.5 parts of active agent, 2.2 parts of accelerator, 6.6 parts of anti-aging agent, 0.7 1 part of softening agent, 4.8 parts of modifying agent and 0.5 part of army green glue were mixed at 120°C for 3.5min, and sulfur was added to vulcanize at 110°C for 0.7h to obtain the main rubber material; wherein, the active agent consisted of 5 parts of zinc oxide and 1.5 parts of part of stearic acid; accelerator consists of 1.3 parts of accelerator DM, 0.2 part of accelerator TS, 0.4 part of accelerator ZDTP and 0.3 part of accelerator D; antioxidant consists of 1.3 parts of antioxidant MB, 0.8 part of antioxidant B...

Embodiment 3

[0080] The preparation method of the military camouflage rubber substrate of the present embodiment, described preparation method comprises the following steps:

[0081] 1) Mix 50 parts of natural rubber, 10 parts of styrene-butadiene rubber and 40 parts of butadiene rubber according to the proportion and masticate for 1 minute, add 60 parts of white carbon black, 6 parts of active agent, 2.2 parts of accelerator, 7.1 parts of anti-aging agent, 1 1 part of softening agent, 4.6 parts of modifying agent and 1 part of army green rubber were mixed at 130°C for 3.5min, and sulfur was added to vulcanize at 90°C for 1h to obtain the main rubber material; wherein, the active agent consisted of 4.5 parts of zinc oxide and 1.5 parts of Composed of stearic acid; accelerator consists of 1 part of accelerator DM, 0.4 part of accelerator TS, 0.3 part of accelerator ZDTP and 0.5 part of accelerator D; anti-aging agent consists of 1.5 parts of anti-aging agent MB, 1 part of anti-aging agent BH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com