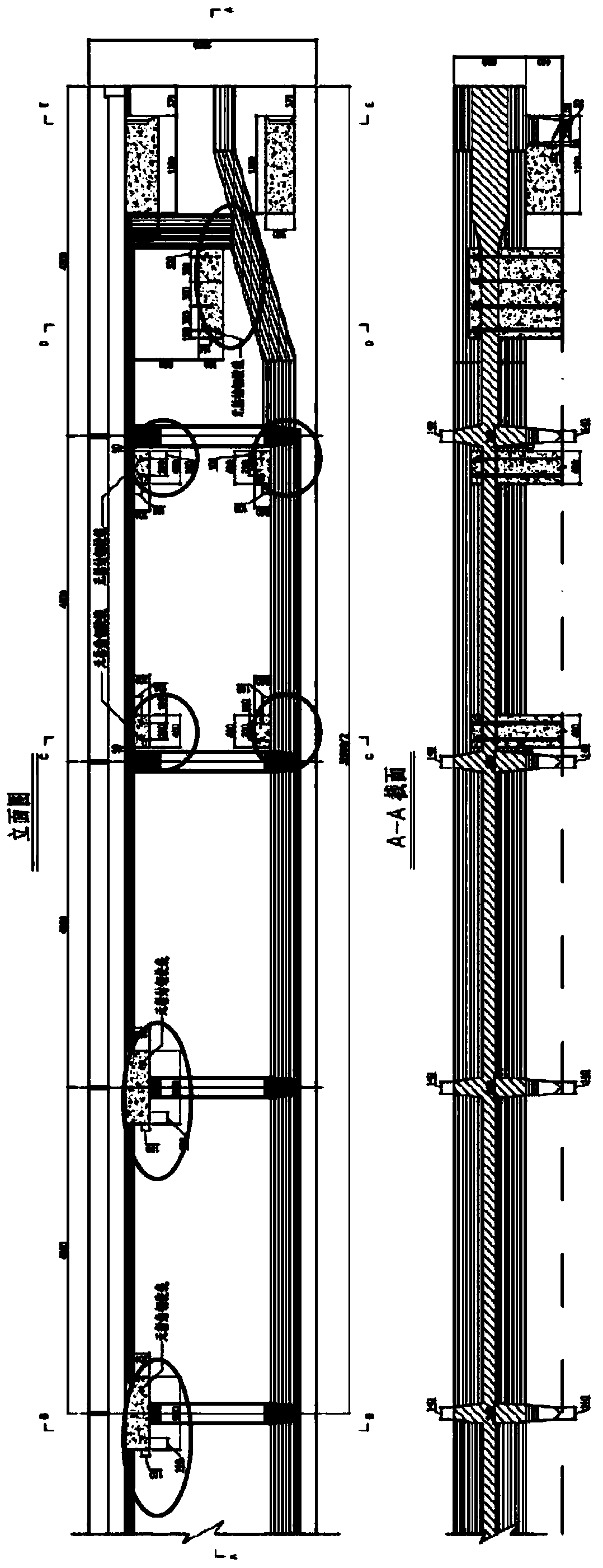

Transverse prestress reinforcement method of railway simply-supported T beam

A technology of transverse prestressing and prestressing steel beams, which is applied in bridge reinforcement, bridge, bridge maintenance, etc., can solve the problems that the reinforcement construction is difficult to meet the preset standards and is not easy to change, and achieve the improvement of transverse stiffness, good precision and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

[0036] Shanxi Yinhuo Railway was built in 1986 and opened to traffic in 1993. It is located in Hequ County, Shanxi Province. It is a local single-track railway connecting Yinta to Huoshan. The total length of the main line is 33.3km. It is a prestressed concrete simply supported girder bridge with a speed limit of 40km / h along the entire line. In 2013, the annual transportation volume of the Yinhuo Line was 8 million tons, and it was a non-electrified railway. In order to meet the new freight volume task, the C64K freight train will be phased out gradually, and then the C80 freight train will be operated, with an expected annual freight volume of 15 million tons. In 2013, the operating unit carried out bridge inspection and load tests on the bridges along the ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com