Eccentric gear transmission device and transmission method thereof

A transmission device and eccentric gear technology, applied in the transmission device, transmission device parts, friction transmission device, etc., can solve the problems of unsuitable flexible piston engines, vulnerable parts, low transmission efficiency, etc., and increase the utilization rate of equipment , Strong interchangeability, stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

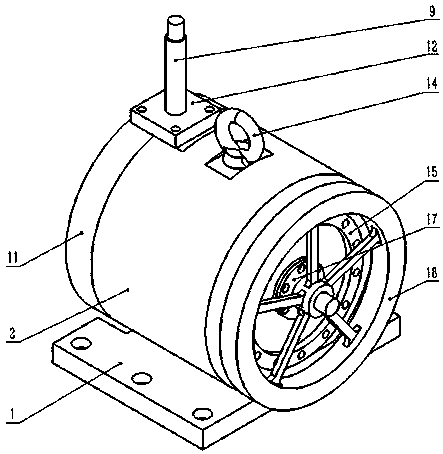

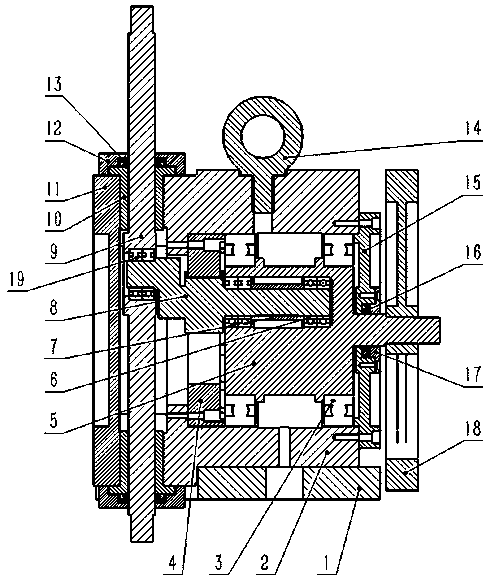

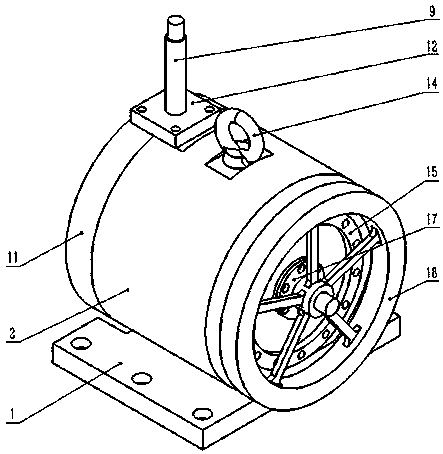

[0036] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention:

[0037] Please refer to the specific structure and usage of the present invention figure 1 and figure 2, an eccentric gear transmission device and a transmission method thereof, comprising a box mounting plate 1, a box body 2, a rolling bearing 3, an inner ring gear 4, an eccentric shaft 5, a gear shaft rolling bearing A6, a sleeve 7, a gear shaft 8, a linear Motion shaft 9, linear bearing 10, box cover 11, linear motion shaft sealing end cover 12, linear skeleton oil seal 13, hoisting ring 14, large end cap 15, rotating skeleton oil seal 16, small end cap 17, flywheel 18, gear shaft rolling bearing B19, the box body 2 is installed on the box body mounting plate 1, the box body 2 is a hollow cylindrical tubular structure, the inner wall of the box body 2 is install...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com