Nuclear reactor pressure vessel connection pipe safety end pre-delivery ultrasonic detection device

A technology for pressure vessels and nuclear reactors, which is applied to measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves to analyze materials, etc. It can solve the problems of high manufacturing costs, many operators, and large space occupation. , to achieve the effects of easy installation, enhanced support stability, and guaranteed axial positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

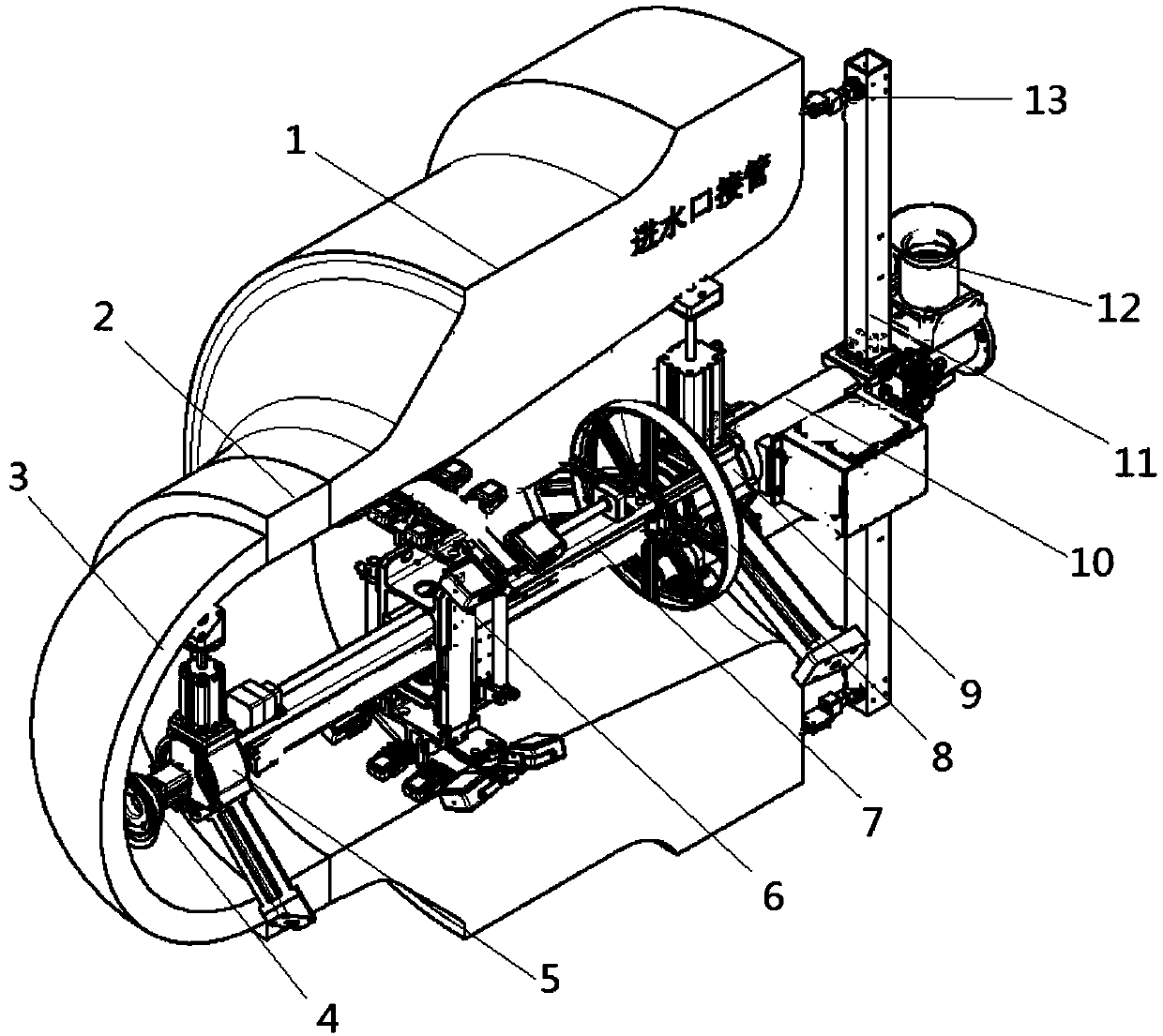

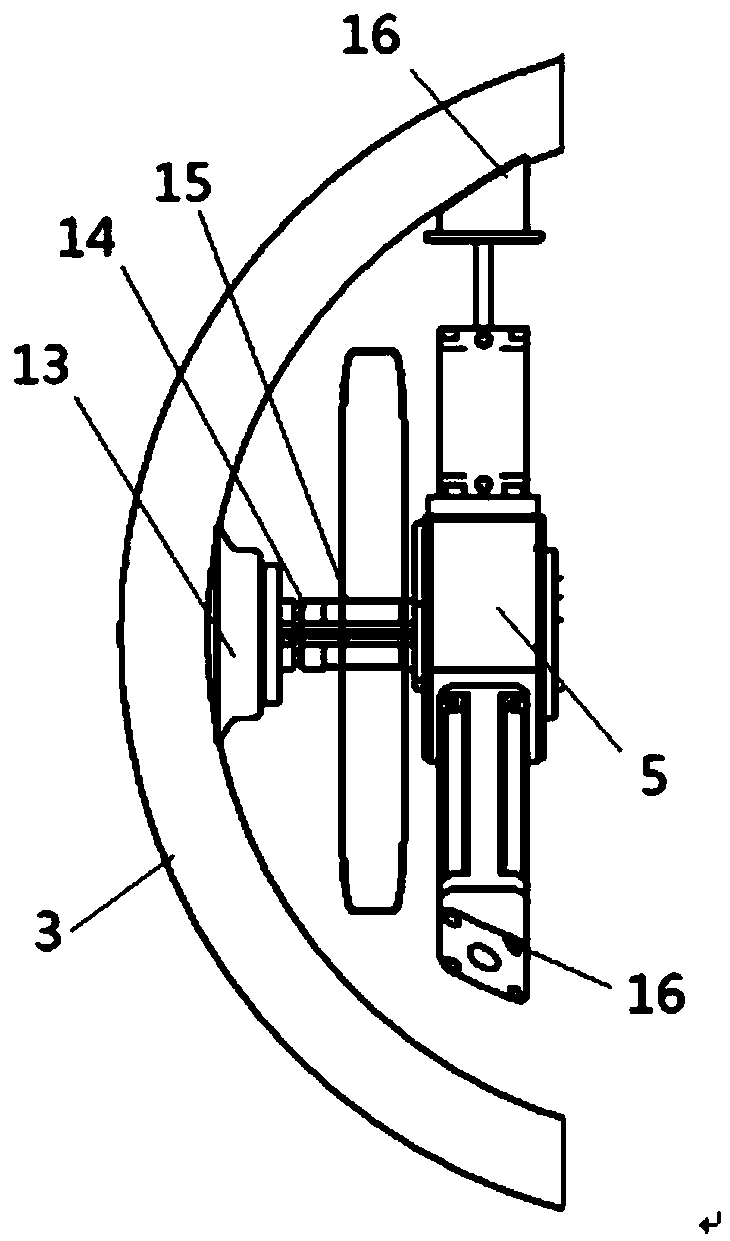

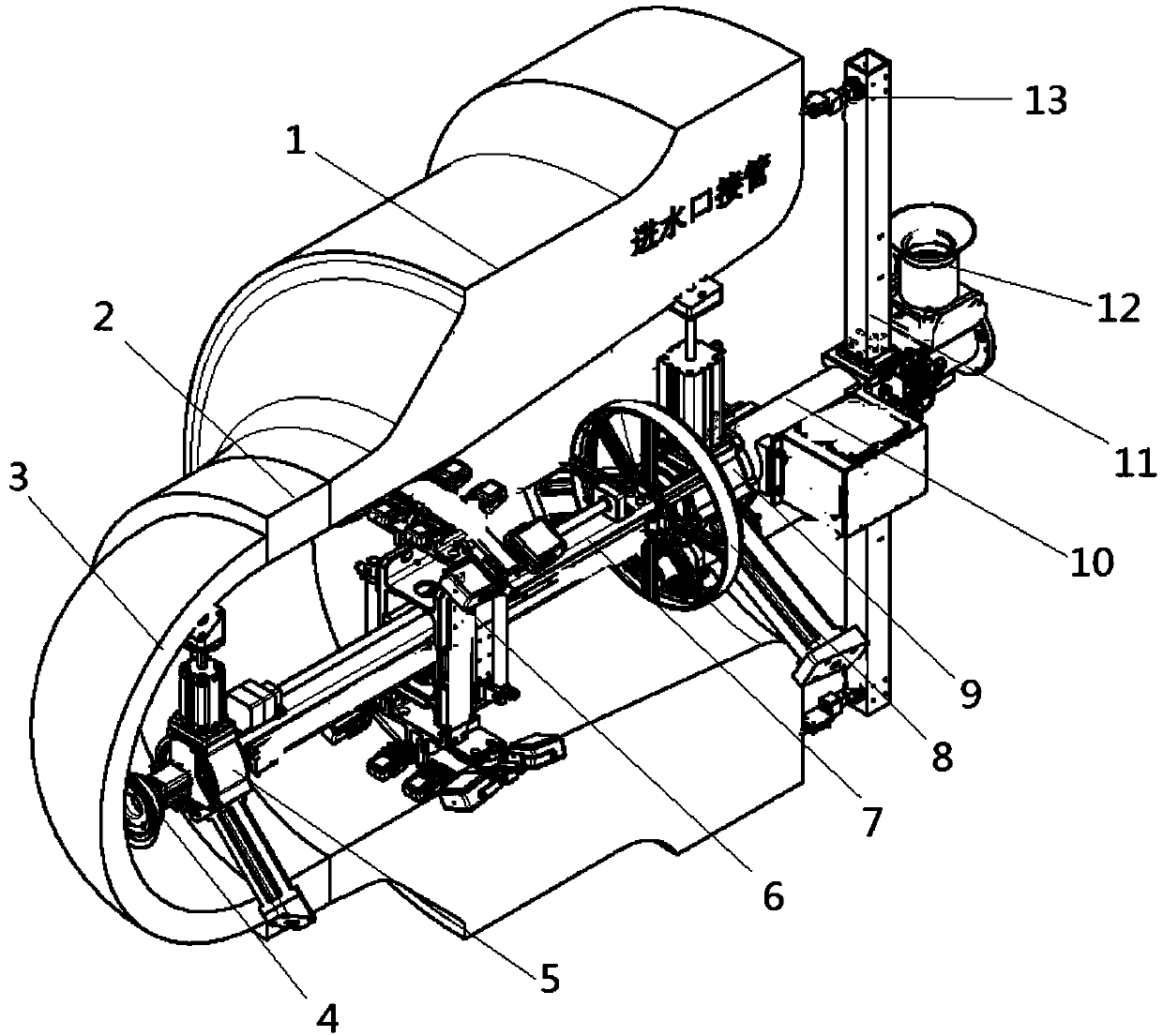

[0024] An ultrasonic inspection device for the safety end of a nuclear reactor pressure vessel, including a suction cup tensile support part 4, a front rotary support part 5, a tray part 6, a linear motion part 7, a circular motion part 8, a rear rotary support part 9, and a frame 10 , gear bar 11, hoisting turning mechanism 12 and limit mechanism 13.

[0025] A circular motion component 8 and a linear motion component 7 are connected between the front rotary support component 5 and the rear rotary support component 9 , and the circular motion component 8 is installed on one side close to the rear rotary support component 9 .

[0026] The front rotary support part 5 and the rear rotary support part 9 not only play the role of supporting and fixing the two ends, but also play the rotary motion support of the circular motion part 8 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com